Key Geocell Specifications: Cell Size, Depth, and Material Strength Explained

When it comes to slope stabilization, soil reinforcement, or erosion control, geocell structures have grow to be a go-to answer in civil engineering and landscaping. But no longer all geocell merchandise operate the same—their effectiveness hinges on three imperative specifications: mobilephone size, depth, and cloth strength. These elements decide how properly a geocell can confine soil, distribute loads, and face up to environmental stress. This information breaks down every key specification, explaining what they mean, how they interact, and why they rely for specific geocell applications. We’ll additionally discover how geocell cloth preferences impact these specs to assist you choose the ideal machine for your project.

Understanding Geocell: The Foundation

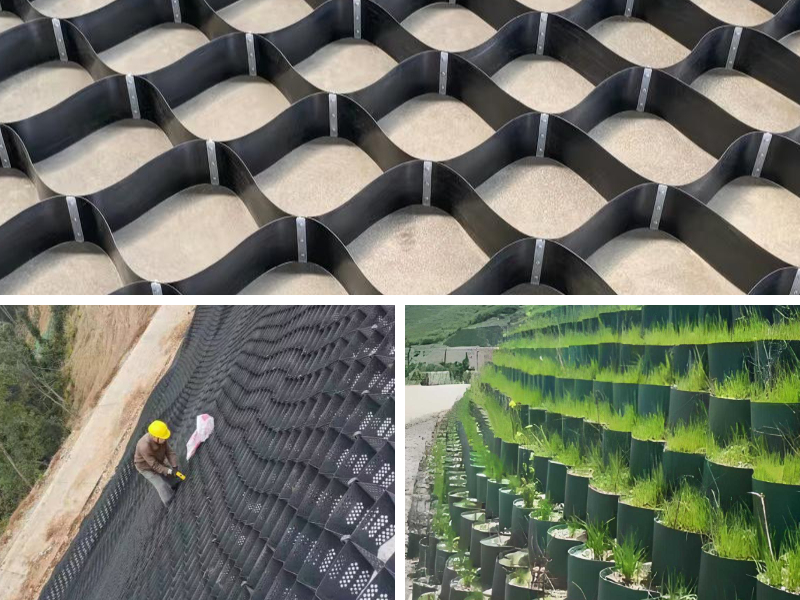

Geocells are three-dimensional, honeycomb-like buildings made from artificial materials. They arrive on-site flat, amplify into inflexible grids, and are stuffed with soil, gravel, or vegetation to create a stable, strengthened composite system. Unlike ordinary reinforcement strategies (such as metal bars or concrete), geocells work with the surrounding soil to enhance its load-bearing potential and stop erosion. Geocell functions vary from dual carriageway embankments and residential landscaping to coastal safety and mining web page stabilization—each requiring tailor-made specs to succeed.

To pick the proper geocell, you have to first apprehend how mobilephone size, depth, and fabric power have an impact on performance. These specs aren’t arbitrary; they’re engineered to fit the special needs of every project.

1. Cell Size: The Shape That Defines Confinement

Cell dimension refers to the dimensions of the character hexagonal or rectangular cells in the geocell grid (e.g., 100mm x 100mm or 200mm x 200mm). It’s one of the most crucial specs due to the fact it immediately influences how nicely the geocell confines infill fabric (soil or aggregate) and distributes loads.

How Cell Size Works: Smaller cells create greater confinement—they lure soil particles tightly, stopping motion and enhancing the composite system’s stiffness. Larger cells permit for extra infill cloth and higher vegetation increase however provide barely much less confinement. The purpose is to in shape telephone measurement to the infill material’s particle size: fine-grained soils (like silt or clay) function quality with smaller cells to stop particle migration, whilst coarse-grained substances (like gravel) can use large cells besides sacrificing stability.

Geocell Applications through Cell Size: For geocell functions like pedestrian paths or residential driveways (where masses are light), large cells (150mm-200mm) are sufficient. For heavy-load initiatives like motorway embankments or industrial yards, smaller cells (50mm-100mm) grant the essential confinement to manage visitors or tools weight. In erosion manage tasks the place vegetation is key, medium-sized cells (100mm-150mm) stability soil retention and plant growth.

2. Depth: The Height That Boosts Load-Bearing Capacity

Geocell depth (or height) is the vertical dimension of every cellphone (e.g., 50mm, 100mm, or 200mm). It works hand-in-hand with mobile measurement to decide the system’s load-bearing potential and resistance to shear failure (when soil slides alongside a plane).

How Depth Works: Deeper cells can keep greater infill material, growing a thicker bolstered layer that distributes hundreds over a large area. This reduces the strain on the underlying soil, stopping contract or collapse. Depth additionally enhances shear resistance: the taller the telephone walls, the extra they withstand the horizontal forces that reason soil to slide. However, deeper geocells are stiffer and may also be much less bendy on irregular terrain, so stability is key.

Geocell Applications through Depth: Shallow geocells (50mm-100mm) are perfect for light-duty geocell functions like landscaping slopes or backyard paths. Medium-depth cells (100mm-150mm) work nicely for residential roads or parking lots. Deep geocells (150mm-300mm) are reserved for heavy-duty projects: dual carriageway embankments, airport runways, or mining waste piles, the place most load-bearing capability is critical.

3. Material Strength: The Backbone of Durability

Geocell cloth electricity refers to the tensile strength, tear resistance, and environmental sturdiness of the artificial cloth used to make the grid. Common geocell substances consist of high-density polyethylene (HDPE), polypropylene (PP), and polyester (PET)—each with special power properties.

Key Strength Metrics: Tensile energy (how tons pressure the cloth can face up to earlier than breaking) and tear resistance (how properly it resists punctures or rips) are the most important. HDPE is the most famous geocell cloth due to the fact it balances excessive tensile strength, UV resistance, and chemical tolerance. PP is extra bendy however has decrease UV resistance, whilst PET affords gorgeous electricity however is greater expensive.

How Material Strength Impacts Performance: A geocell with low tensile power will stretch or tear below heavy loads, failing to confine the infill material. Poor UV resistance leads to degradation in sunlight, shortening the system’s lifespan. Chemical resistance is crucial for geocell functions involving industrial sludge, saltwater, or acidic soils—HDPE and PET excel here, whilst PP may also require stabilizers.

Geocell Applications through Material: HDPE geocells are versatile, appropriate for most functions from landscaping to highways. PP geocells work for temporary or included initiatives (to keep away from UV exposure), like transient building web page stabilization. PET geocells are used for high-stress, long-term projects: coastal erosion control, bridge abutments, or industrial sites.

How to Balance the Three Specifications

The first-rate geocell gadget isn’t simply about deciding on one specification—it’s about balancing phone size, depth, and geocell fabric energy to suit your project’s needs. Here’s a step-by-step approach:

1. Define Project Goals: Are you stabilizing a slope, reinforcing a road, or controlling erosion? Each geocell utility has one of a kind priority specs (e.g., erosion manage prioritizes mobile measurement for vegetation, whilst avenue reinforcement prioritizes depth and fabric strength).

2. Evaluate Loads & Soil Type: Heavy hundreds (traffic, equipment) require smaller cells, deeper grids, and more desirable materials. Fine soils want smaller cells; coarse soils can use large ones.

3. Consider Environmental Conditions: Sunny, coastal, or industrial websites want UV-resistant, chemical-tolerant substances (HDPE/PET). Shaded or brief websites can use PP.

4. Test Compatibility: Ensure the geocell specs work with your infill material—e.g., small cells with nice soil, deep cells with gravel.

Common Mistakes to Avoid

When choosing geocell specifications, steer clear of these errors:

Mismatching Cell Size to Soil: Using giant cells with quality soil leads to particle migration and erosion.

Undersizing Depth for Loads: Shallow geocells underneath heavy visitors will settle or collapse.

Ignoring Material Durability: Using PP in sunny areas except UV stabilizers motives untimely failure.

Over-Engineering: Choosing deep, small-cell geocells for light-duty tasks wastes money—balance specs to keep away from overspending.

Conclusion: Specs That Deliver Results

Cell size, depth, and geocell fabric power are the constructing blocks of a profitable geocell system. By grasp how every specification works and how they interact, you can pick a geocell that meets the special needs of your geocell applications—whether it’s a residential backyard slope or a toll road embankment.

Remember: there’s no “one-size-fits-all” geocell. The key is to align specs with mission goals, soil type, loads, and environmental conditions. With this guide, you’re equipped to pick out a geocell gadget that can provide durability, efficiency, and long-term performance—ensuring your mission stands the check of time.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province