How to Choose the Right Geomat for Erosion Control: Key Factors to Consider

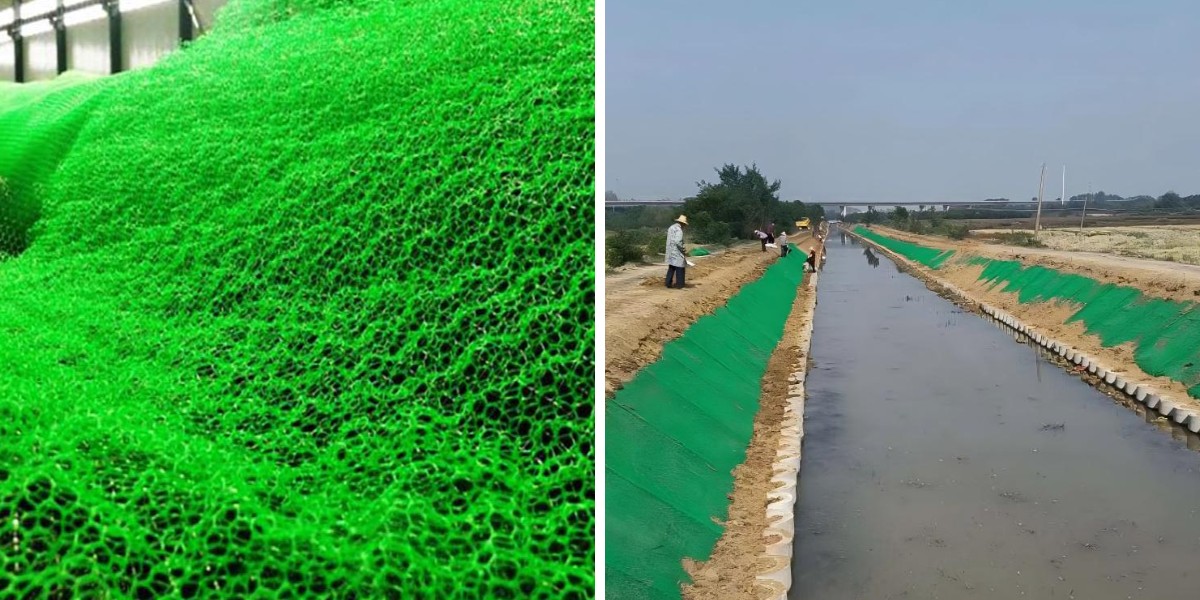

Erosion poses an intense hazard to development sites, agricultural lands, riverbanks, and coastal areas, main to soil loss, infrastructure damage, and ecological imbalance. Geomat, an synthetic or herbal fibrous cloth designed for erosion control, has turn out to be a go-to answer for stabilizing soil and stopping sediment runoff. However, now not all geomats are created equal—choosing the proper one requires cautious evaluation of site-specific needs. This information breaks down the key elements to think about when choosing a geomat for erosion control, making sure your geomat erosion manipulate undertaking can provide long-lasting results.

1. Soil Type: The Foundation of Geomat Selection for Erosion Control

Soil composition immediately influences how a geomat interacts with the ground, making it the first thing to assess. Different soil sorts have special houses (e.g., particle size, cohesion, permeability) that demand precise geomat facets to maximize stability.

1.1 Sandy Soils: Prioritize Anchorage and Sediment Retention

Sandy soils are loose, low in cohesion, and enormously permeable, making them inclined to wind and water erosion. For these soils, a geomat with excessive tensile power and a dense, interlocking shape is essential. Non-woven needle-punched geomats—made from polypropylene or polyester—are perfect here. Their fibrous matrix traps sand particles, stopping them from being washed away, whilst their flexibility permits them to conform to soil contours. Additionally, the porous nature of these geomats promotes water infiltration besides compromising erosion control. When the use of a geomat for sandy soil erosion control, make sure it has a minimal tensile power of 10 kN/m to face up to pulling forces from runoff or wind; this ensures the geomat helps advantageous geomat erosion manage in sandy environments.

1.2 Clay Soils: Focus on Drainage and Root Integration

Clay soils are cohesive however slow-draining, regularly main to floor water pooling and crusting—both of which weaken soil shape and extend erosion risk. For clay soils, a geomat that balances water drainage and root assist is critical. Woven geomats, with their structured mesh design, excel here: they enable extra water to get away whilst imparting a steady framework for vegetation growth. Vegetation roots penetrate the geomat and bind clay particles, bettering long-term stability. Additionally, think about a geomat dealt with with biodegradable additives; these substances spoil down over time as vegetation establishes, lowering environmental impact. For clay soil geomat erosion manage projects, choose for a geomat with a permeability charge of at least 10⁻³ m/s to keep away from waterlogging, as acceptable drainage is key to profitable geomat erosion manipulate in clay soils.

1.3 Loamy Soils: Balance Flexibility and Durability

Loamy soils (a combine of sand, silt, and clay) are reasonably cohesive and permeable, making them much less erosion-prone however nevertheless in want of protection. A versatile geomat—such as a composite geomat (combining woven and non-woven layers)—works excellent here. The non-woven layer retains sediment and helps seed germination, whilst the woven layer provides tensile energy to face up to reasonable runoff. This mixture ensures the geomat adapts to loamy soil’s balanced properties, supplying each non permanent erosion manage and long-term vegetation support. When choosing a geomat for loamy soils, verify that it meets nearby environmental requirements for biodegradability, as loamy soils are regularly used for agriculture or landscaping; this alignment ensures the geomat contributes to sustainable geomat erosion control.

2. Environmental Conditions: Matching Geomat to Site-Specific Challenges

Environmental factors—including rainfall, slope steepness, temperature, and vegetation goals—determine how nicely a geomat performs over time. Ignoring these prerequisites can lead to untimely geomat failure and ineffective erosion control, undermining the success of your geomat erosion manage project.

2.1 Rainfall and Runoff: Select Geomats for Water Resistance

High rainfall areas journey excessive floor runoff, which exerts widespread shear pressure on soil and geomats. For these sites, a geomat with excessive water resistance and erosion resistance is non-negotiable. Polypropylene geomats are favored here: they are hydrophobic (repel water), resistant to rotting, and preserve their electricity even when saturated. Additionally, seem to be for geomats with a “rough” floor texture—this slows down runoff velocity, lowering its erosive power. For areas with annual rainfall exceeding 1,500 mm, a geomat with a thickness of 5-10 mm is advocated to face up to heavy runoff; in contrast, low-rainfall areas can use thinner, greater porous geomats (e.g., 2-3 mm non-woven geomats) that center of attention on wind erosion manipulate whilst permitting confined water infiltration. Both alternatives are tailor-made to optimize geomat erosion manipulate based totally on rainfall patterns.

2.2 Slope Steepness: Prioritize Geomat Tensile Strength and Adhesion

Steeper slopes (greater than 30 degrees) face greater gravitational forces, growing the threat of soil sliding and geomat detachment. For steep slopes, a geomat with awesome tensile electricity and anchoring abilities is essential. Reinforced geomats—incorporating artificial fibers or mesh layers—offer the required strength, with tensile values ranging from 15-25 kN/m. Additionally, use soil anchors or staples to impervious the geomat to the slope, making sure it does no longer shift at some point of heavy rain or wind. For slopes between 15-30 degrees, a fashionable woven or non-woven geomat (10-15 kN/m tensile strength) suffices, however continually overlap geomat edges through 15-20 cm to create a non-stop barrier. For geomat erosion manage on slopes, keep away from light-weight geomats (less than 200 g/m²) as they are susceptible to being lifted via wind or runoff, which would compromise geomat erosion manage effectiveness.

2.3 Temperature and Climate: Ensure Geomat Durability

Extreme temperatures—both warm and cold—can degrade geomats over time, threatening the toughness of geomat erosion control. In high-temperature areas (e.g., deserts), geomats made from UV-stabilized polypropylene are critical; these substances face up to solar injury and hold their shape at temperatures up to 60°C. In bloodless climates, the place freezing and thawing cycles occur, a bendy geomat is key—rigid substances may additionally crack when soil expands and contracts. Polyester geomats are best here, as they stay bendy at temperatures as low as -20°C. For coastal areas, which face saltwater exposure, select a corrosion-resistant geomat (e.g., HDPE geomats) to stop degradation from salt spray. When evaluating a geomat for harsh climates, test its “service life” rating—aim for 5-10 years for brief tasks (e.g., building sites) or 15+ years for everlasting geomat erosion manage (e.g., riverbanks).

3. Performance Parameters: Evaluating Geomat Quality for Long-Term Erosion Control

Beyond soil and environmental factors, assessing a geomat’s overall performance metrics ensures it meets the needs of your geomat erosion manage project. Key parameters encompass tensile strength, permeability, vegetation compatibility, and durability.

3.1 Tensile Strength: Measure Geomat Resistance to Pulling Forces

Tensile energy (the most pressure a geomat can stand up to earlier than breaking) is fundamental for withstanding runoff, wind, and soil movement—all key threats to geomat erosion control. For most geomat erosion manipulate projects, a minimal tensile electricity of 10 kN/m (for flat areas) or 15 kN/m (for slopes) is recommended. To affirm this, request check reviews from manufacturers—look for compliance with worldwide requirements like ISO 10319 (for geosynthetics tensile testing). Avoid geomats with inconsistent energy (e.g., various with the aid of extra than two kN/m across samples), as they may additionally fail at vulnerable points. Additionally, think about “elongation at break”—a geomat with 15-20% elongation is ideal, as it can stretch barely barring breaking, adapting to minor soil motion and sustaining geomat erosion manage over time.

3.2 Permeability: Balance Drainage and Sediment Retention

Permeability (the price at which water passes thru the geomat) immediately influences soil moisture degrees and erosion risk, making it a key thing in geomat erosion control. A geomat that is too impermeable motives water pooling, whilst one that is too permeable approves sediment to escape. For most projects, a permeability fee of 10⁻³ to 10⁻² m/s is optimal—this approves water to drain whilst trapping soil particles. To take a look at permeability, use the regular head technique (per ASTM D4491) and make certain outcomes are regular throughout the geomat’s surface. For initiatives centered on vegetation increase (e.g., reforestation), pick out a permeable geomat that lets in water and vitamins to attain seeds, aiding germination and root development; this synergy between geomat and vegetation enhances long-term geomat erosion control.

3.3 Vegetation Compatibility: Support Natural Stabilization

Vegetation is a key aspect of long-term erosion control, so choosing a geomat that works with plant life is crucial for high-quality geomat erosion control. Biodegradable geomats (e.g., coconut coir or straw geomats) are perfect for initiatives the place vegetation will in the end change the geomat—they destroy down over 6-12 months, imparting brief help whilst seeds grow. Non-biodegradable geomats (e.g., polypropylene) work for everlasting tasks however require openings or pores giant ample for roots to penetrate (at least two mm in diameter). Additionally, reflect onconsideration on pre-seeded geomats—these come with grass or native plant seeds embedded, saving time and ensuring vegetation aligns with nearby ecosystems. For geomat erosion manage projects, continually fit the geomat’s degradation price to the vegetation’s increase timeline; for example, fast-growing grasses pair properly with 6-month biodegradable geomats, making sure non-stop geomat erosion manipulate as vegetation establishes.

Conclusion

Choosing the proper geomat for erosion manipulate is a strategic system that hinges on grasp your site’s soil type, environmental conditions, and overall performance needs. By prioritizing soil-geomat compatibility, adapting to nearby local weather challenges, and verifying key overall performance metrics, you can make sure your geomat erosion manage venture is effective, durable, and cost-efficient. Remember: a well-selected geomat no longer solely prevents soil loss however additionally helps ecological restoration, turning susceptible areas into stable, healthful landscapes. Whether you’re working on a development site, farm, or riverbank, make investments time in evaluating these factors—your geomat erosion manipulate project’s success relies upon on it.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province