Geomembrane Waterproofing for Tunnels & Underground Structures

Introduction: The Critical Role of Impermeable Barriers in Subterranean Engineering

Underground constructions like tunnels, basements, and utility vaults face relentless challenges from groundwater pressure, chemical corrosion, and geological instability. Traditional waterproofing methods normally fail to address the complexity of these environments, essential to pricey repairs and operational disruptions. This is the place HDPE geomembrane science emerges as a game-changer. As a synthetic impermeable geomembrane engineered from high-density polyethylene (HDPE), this cloth gives a durable, flexible, and chemically resistant barrier succesful of withstanding extreme subterranean conditions. This facts explores the science, applications, and blessings of HDPE-based choices for tunnel and underground waterproofing, emphasizing their role in current day infrastructure resilience.

Section 1: Understanding HDPE Geomembrane: The Foundation of Underground Waterproofing

1.1 What Makes HDPE Liner Sheet Unique?

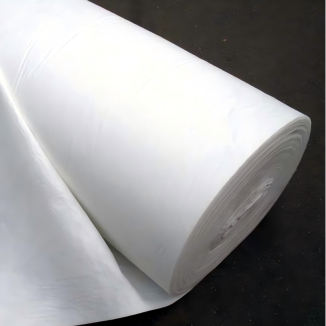

HDPE geomembrane is a factory-fabricated sheet composed of 97.5% HDPE resin blended with 2.5% carbon black, antioxidants, and UV stabilizers. This composition gives you it extremely good properties:

Impermeability: With a hydraulic conductivity fee as low as 1×10⁻¹² cm/s, HDPE liner sheet effectively blocks water, gases, and contaminants.

Mechanical Strength: Tensile electrical energy exceeds 20 MPa, while elongation at smash reaches 300%, enabling it to take in flooring action without tearing.

Chemical Resistance: Unaffected by using acids, alkalis, and salts, making it best for aggressive soil conditions.

UV Stability: Carbon black elements prevent degradation from prolonged daylight hours publicity all thru construction.

1.2 Manufacturing Excellence: The Triple Co-Extrusion Advantage

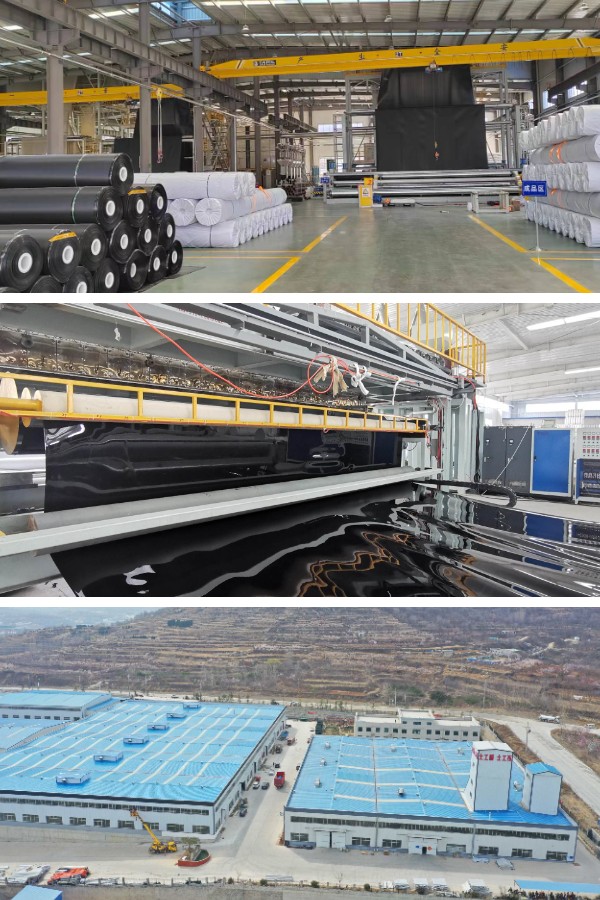

Advanced manufacturing techniques like triple co-extrusion make sure uniform thickness and molecular orientation at some point of the HDPE geomembrane sheet. This system creates a homogenous structure free from susceptible points, vital for functions the vicinity pressure differentials exceed 5 bar (e.g., deep tunnels under the water table). Modern offerings can produce rolls up to eight meters giant and 280 meters long, minimizing seams and set up time.

Section 2: Why HDPE Dominates Tunnel Waterproofing Projects

2.1 Engineering Challenges in Underground Environments

Tunnels confront three predominant waterproofing threats:

Hydrostatic Pressure: Water-saturated soils exert forces that can deform or puncture inferior materials.

Chemical Attack: Sulfates, chlorides, and herbal acids in groundwater degrade normal membranes over time.

Construction Damage: Sharp rock fragments and heavy tools danger abrasion for the period of installation.

2.2 HDPE’s Problem-Solving Capabilities

Pressure Resistance: A 2.5mm-thick HDPE liner sheet withstands 100-meter water heads, equal to 1 MPa pressure.

Puncture Resistance: Field assessments showcase HDPE geomembrane resists penetration from 20mm diameter metallic rods at 300 N force.

Self-Healing Properties: Minor punctures from backfill stones seal robotically under stress due to HDPE’s viscoelastic nature.

Case Study: In a 2024 mountain tunnel project, HDPE geomembrane reduced water ingress by using ability of 98% in distinction to normal bituminous coatings, however each day temperature fluctuations from -15°C to 35°C.

Section 3: Application Scenarios for Impermeable Geomembrane Systems

3.1 Tunnel Lining Waterproofing

For cut-and-cover tunnels, HDPE geomembrane is hooked up between the primary concrete lining and secondary shotcrete layer. Key blessings include:

Dual Protection: Acts as a standalone barrier at the same time as enhancing concrete’s crack-bridging capacity.

Thermal Compatibility: Remains flexible at -40°C, stopping brittleness in cold climates.

Installation Efficiency: A 6-person crew can weld 1,000m²/day the use of hot-air guns, decreasing challenge timelines by using way of 40%.

3.2 Underground Car Parks & Basements

In town environments, HDPE liner sheet serves as a vapor barrier and radon gas shield. Its low permeability (1×10⁻¹⁰ cm/s for water vapor) prevents moisture accumulation that factors concrete spalling and steel corrosion.

3.3 Utility Vaults & Pipeline Tunnels

For structures housing electrical or dialog cables, HDPE geomembrane’s dielectric power (20 kV/mm) gives electrical insulation while blocking off off moisture ingress. This extends cable lifespan thru stopping hydrolysis-induced degradation.

Section 4: Installation Best Practices for Long-Term Performance

4.1 Subgrade Preparation

Surface Smoothing: Remove protrusions >5mm the use of grinding tools to give up stress concentrations.

Drainage Integration: Install geocomposite drainage layers below the HDPE liner sheet to manage seepage forces.

Slope Stabilization: For inclined tunnels, anchor the membrane with HDPE strips every three meters to prevent sliding.

4.2 Welding Techniques

Hot-Air Welding: Preferred for situation seams, attaining bond strengths >90% of mum or dad material.

Extrusion Welding: Used for detailing spherical penetrations, with melted HDPE rod filling gaps completely.

Non-Destructive Testing: Air channel tests comprehend leaks as small as 0.5mm diameter at 200 mbar pressure.

4.3 Quality Control Measures

Batch Testing: Each manufacturing lot undergoes tensile, tear, and puncture assessments per ASTM D4833 standards.

Installation Certification: Crews want to total manufacturer-approved teaching applications before than working on indispensable infrastructure projects.

Lifetime Monitoring: Embedded sensors in some HDPE geomembrane constructions track stress and leakage in genuine time.

Section 5: Comparative Analysis: HDPE vs. Alternative Waterproofing Methods

5.1 HDPE vs. PVC-P Geomembranes

While PVC-P offers larger elongation (400% vs. 300%), HDPE’s pinnacle of the line chemical resistance makes it preferable for:

Acidic soils (pH <5)

High-temperature environments (>60°C)

Projects requiring 100+ 12 months lifespans

5.2 HDPE vs. Bentonite Clay Liners

Sodium bentonite swells to shape a low-permeability barrier on the other hand fails in:

Dry stipulations (requires regular moisture)

High-salinity soils (ions disrupt swelling)

Areas with root penetration risks

5.3 Cost-Benefit Breakdown

Initial material expenditures for HDPE geomembrane common

4.50–6.00/m², alternatively lifecycle monetary financial savings exceed 30% due to:

Reduced renovation (no recoating needed)

Lower insurance plan sketch premiums (classified as “low-risk” by way of way of engineering standards)

Faster mission completion (fewer local weather delays)

Section 6: Future Innovations in HDPE Geomembrane Technology

6.1 Nano-Enhanced Formulations

Researchers are incorporating graphene oxide nanoparticles into HDPE to create membranes with:

50% increased tensile strength

Self-cleaning homes via capacity of photocatalytic reactions

Enhanced UV resistance for above-ground applications

6.2 Smart Geomembranes

Emerging merchandise mix fiber-optic sensors to detect:

Micro-tears previously than they propagate

Chemical changes indicating degradation

Temperature gradients affecting fabric properties

6.3 Biodegradable Additives

For short tunnels (e.g., mining accessways), biodegradable HDPE blends restriction environmental have an effect on even as conserving 90% of famous ordinary overall performance all thru company life.

Conclusion: The Impermeable Future of Underground Infrastructure

As urbanization pushes development deeper underground, the demand for reliable waterproofing selections grows exponentially. HDPE geomembrane and HDPE liner sheet utilized sciences have validated their simply really worth at some point of 50+ years of vicinity applications, imparting unmatched durability, versatility, and price efficiency. By adhering to rigorous set up necessities and leveraging continuous fabric innovations, engineers can now graph subterranean constructions that stay tons longer than their supposed lifespans even as minimizing environmental disruption. For mission vendors in search of a future-proof waterproofing strategy, HDPE stays the gold present day in tunnel and underground construction.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province