Field Quality Control (QC) for HDPE Liners: Ensuring Weld Integrity

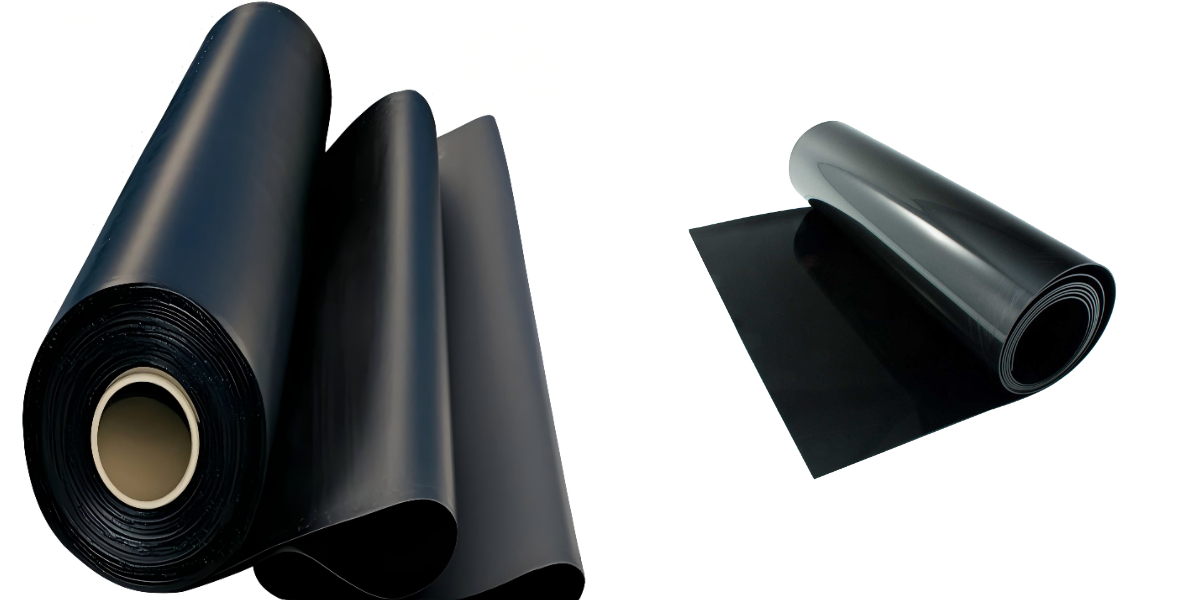

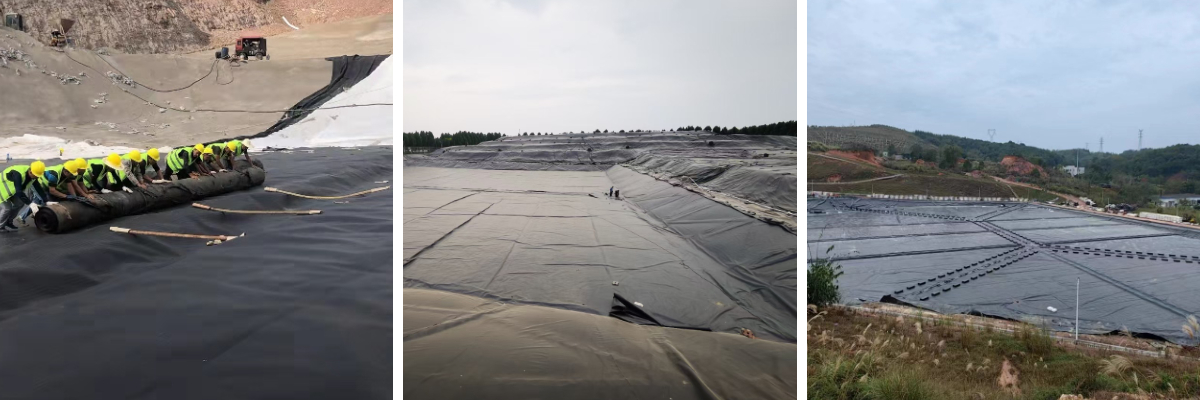

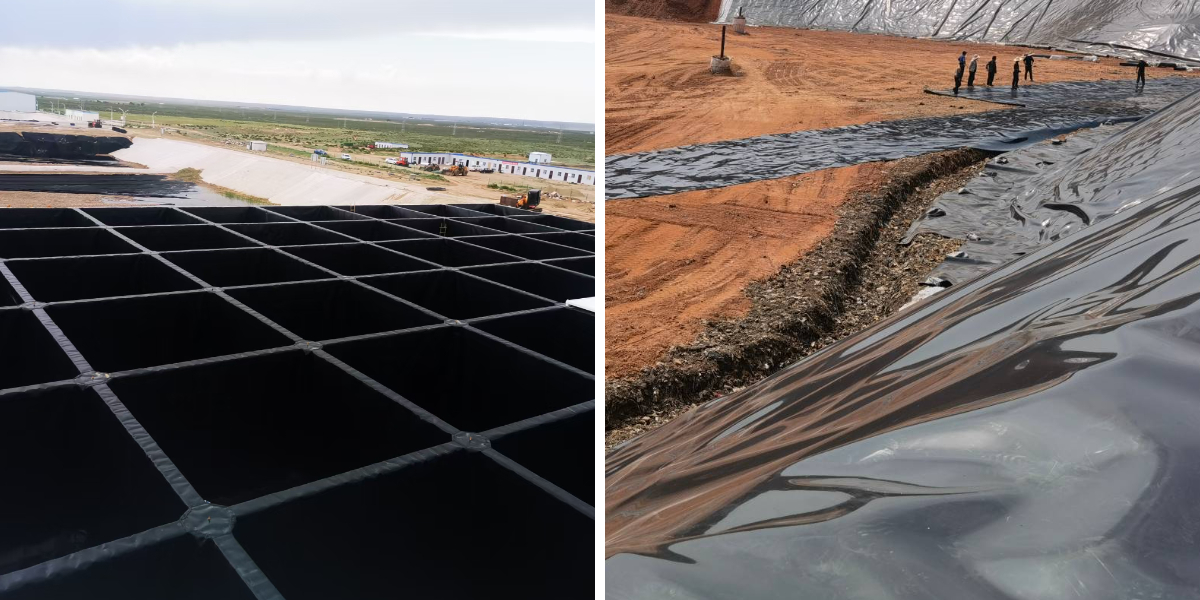

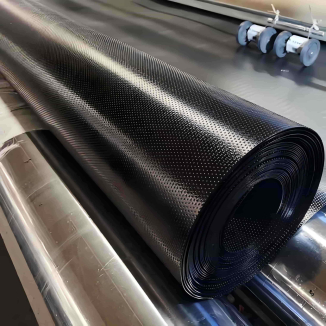

HDPE liners are the spine of containment structures in landfills, water reservoirs, wastewater remedy facilities, and industrial sites—relying absolutely on weld integrity to keep their position as a dependable impermeable geomembrane. A single fallacious weld can compromise the complete system, main to leaks, environmental contamination, and high priced repairs. Field Quality Control (QC) is the unsung hero in stopping these risks, serving as the last line of protection to make certain each seam of a hdpe geomembrane liner meets strict enterprise standards. This information breaks down the vital aspects of subject QC for HDPE liners, from pre-weld preparations to post-weld testing, highlighting how rigorous procedures shield the overall performance of hdpe geomembrane systems.

Why Field QC Is Non-Negotiable for HDPE Liner Systems

A hdpe geomembrane’s popularity for sturdiness and impermeability solely holds if its welds are flawless. Field conditions—temperature fluctuations, wind, dust, and uneven terrain—pose steady threats to weld quality. Unlike managed manufacturing unit settings, outside set up introduces variables that can weaken seams, even with knowledgeable operators and top-tier equipment. Field QC mitigates these dangers through monitoring each and every step of the welding process, catching problems earlier than they boost into device failures. Beyond compliance with environmental regulations, nice QC ensures long-term performance: a well-inspected hdpe geomembrane liner can remaining 30+ years, whilst a liner with untested welds can also fail inside months.

Pre-Weld QC: Laying the Foundation for Strong Seams

Weld integrity starts offevolved earlier than the first bead is laid. Pre-weld QC focuses on making ready the hdpe geomembrane, equipment, and web page to put off variables that ought to compromise welds:

1. Material Inspection

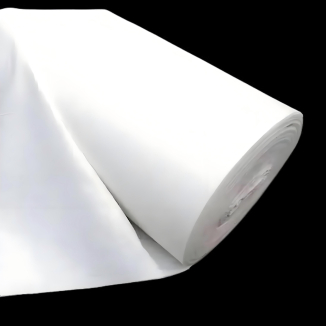

Verify that the hdpe geomembrane liner meets undertaking specifications—check thickness, density, and UV stabilization. Inspect rolls for injury (rips, punctures, or chemical contamination) at some point of transport and storage. Even minor floor defects can intrude with warmness switch at some point of welding, so any compromised fabric have to be trimmed or changed earlier than installation.

2. Site and Surface Preparation

Ensure the liner set up floor is clean, dry, and free of debris, rocks, or sharp objects that ought to puncture the hdpe geomembrane or create uneven welding conditions. Secure the liner to forestall motion all through welding—wind-driven shifts can purpose misalignment of seams, main to susceptible bonds. In intense temperatures (below 10°C or above 35°C), alter set up timelines or use climate-control measures to preserve the liner inside foremost welding temperature ranges.

3. Equipment Calibration

HDPE welding machines (wedge welders, extrusion welders) have to be calibrated day by day to make certain steady heat, pressure, and speed. Test welds on scrap portions of the identical hdpe geomembrane fabric to validate settings—adjust temperature or strain if check seams fail preliminary checks. Faulty gear is the main motive of inconsistent welds, so ordinary calibration is non-negotiable.

In-Weld QC: Monitoring Seams in Real Time

During welding, QC inspectors work alongside operators to screen the process, making sure adherence to requirements and addressing problems immediately:

1. Seam Alignment and Preparation

Ensure liner panels are overlapped efficaciously (typically 15–30 cm for wedge welding) and aligned straight. Clean overlap areas with lint-free cloths and accredited solvents to put off dirt, oil, or moisture—contaminants create gaps in the weld. Inspect side trim: jagged or uneven edges need to be re-cut to create a smooth, uniform floor for welding.

2. Welding Parameter Monitoring

Track heat, pressure, and journey velocity at some point of the welding process. For wedge welding, affirm the warm wedge temperature stays inside the material’s top of the line range; for extrusion welding, display the molten resin temperature and bead size. Any deviation (e.g., a drop in warmness due to wind) requires pausing the procedure to readjust, stopping vulnerable seams.

3. Visual Inspection of Welds

Perform real-time visible exams on each and every weld. A exceptional seam must have a consistent, uniform bead (for extrusion welding) or smooth, fused edges (for wedge welding) with no gaps, bubbles, or burn marks. If visible defects are detected, mark the place for restore and re-inspection earlier than proceeding.

Post-Weld QC: Testing for Impermeability and Strength

Post-weld trying out is the last step to verify weld integrity, the usage of standardized techniques to notice hidden flaws:

1. Air Pressure Testing

The most frequent check for hdpe geomembrane liner welds, air strain checking out includes sealing a part of the seam (typically 1–2 meters) and injecting air to a targeted pressure. Monitor strain tiers over a set time—if stress drops, it suggests a leak. This technique is particularly positive for detecting small gaps or pinholes in wedge welds.

2. Vacuum Testing

Ideal for large, flat weld areas or extrusion welds, vacuum trying out makes use of a vacuum container positioned over the seam. A cleaning soap answer is utilized to the weld; if bubbles shape when vacuum stress is applied, a leak is present. This non-destructive take a look at is speedy and wonderful for figuring out each floor and subsurface flaws.

3. Peel and Shear Testing

For adverse checking out (performed on pattern welds, now not the authentic liner), peel and shear exams measure the pressure required to separate welded panels. A weld need to fail in the hdpe geomembrane cloth itself, no longer at the seam—indicating the weld is more advantageous than the liner. This take a look at validates the universal electricity of the welding process, now not simply character seams.

Repair and Documentation: Closing the QC Loop

Any weld failing post-weld trying out requires immediately repair. Repairs are made the use of the identical welding approach as the unique seam, with extra overlap round the faulty area. Repaired seams bear the equal checking out method to make sure they meet standards. Equally necessary is documentation: hold exact archives of pre-weld inspections, gear calibration, in-weld observations, and take a look at results. This forms serves as proof of compliance, aids in future maintenance, and affords a historic document of the hdpe geomembrane liner’s integrity.

Conclusion: QC as the Guardian of HDPE Liner Performance

Field Quality Control is no longer simply a step in HDPE liner installation—it’s the cornerstone of a reliable, long-lasting impermeable geomembrane system. From pre-weld fabric exams to post-weld stress testing, each QC measure works to make certain that hdpe geomembrane welds are strong, consistent, and leak-proof. For task managers, contractors, and environmental professionals, investing in rigorous subject QC is an funding in peace of mind: it reduces the hazard of steeply-priced repairs, ensures regulatory compliance, and protects the surroundings from contamination.

In the world of containment systems, a hdpe geomembrane liner is only as right as its welds. By prioritizing discipline QC, you’re no longer simply constructing a liner—you’re constructing a machine that will stand the check of time, handing over on the promise of HDPE’s sturdiness and impermeability for a long time to come.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province