Eco-Friendly Geotextile Cloth: Sustainable Options for Green Projects

As inexperienced projects—from ecological restoration to low-carbon infrastructure—gain international momentum, the demand for substances that combination overall performance with sustainability has in no way been higher. Geotextile cloth, a workhorse in development and landscaping, is no exception. Traditional geotextile often depends on fossil fuel-derived plastics or poisonous manufacturing processes, however eco-friendly options are altering the game: they’re made from renewable or recycled materials, manufactured with minimal carbon footprints, and designed to keep away from long-term environmental harm. These sustainable alternatives meet core geotextile wishes (erosion control, soil reinforcement, drainage) whilst aligning with carbon-neutral and waste-reduction goals. Below are 4 necessary pillars of eco-friendly geotextile cloth, plus how to pick out the proper one for your inexperienced project.

1. Sustainable Material Sources: The Foundation of Eco-Friendly Geotextile Cloth

The environmental influence of geotextile cloth starts with its uncooked materials. Eco-friendly preferences prioritize sources that decrease reliance on virgin plastics and decrease useful resource depletion, falling into two key classes tailor-made to distinctive challenge timelines.

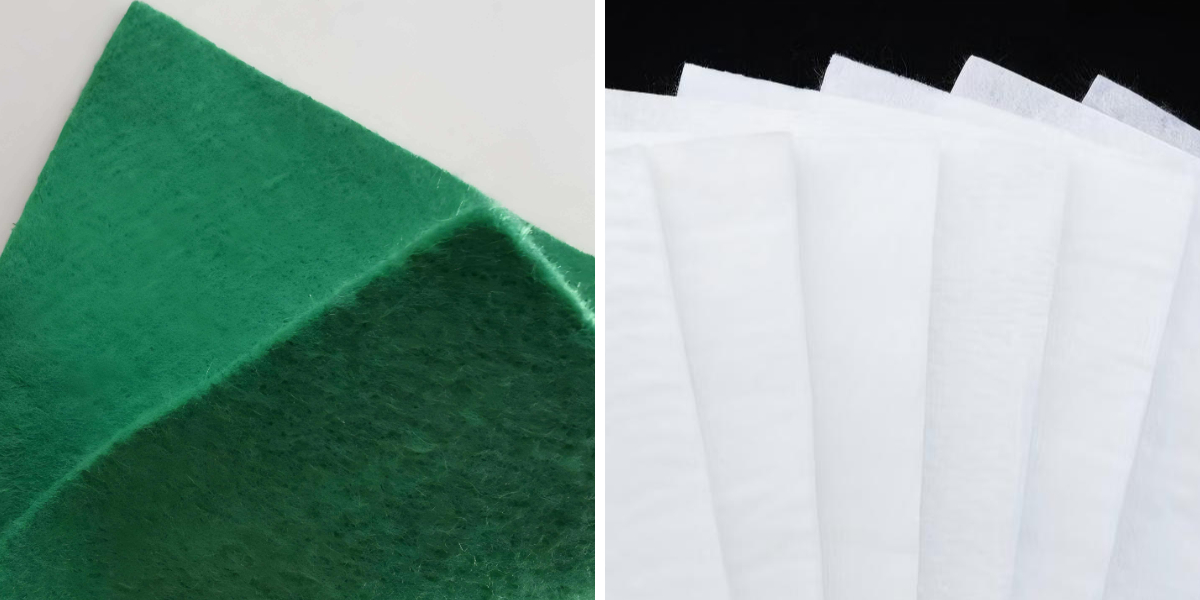

Natural, Biodegradable Fibers: For Temporary Green Projects

Natural fibers are best for temporary initiatives (e.g., seasonal erosion control, transient vegetation establishment) the place biodegradation eliminates post-project waste, as they come from renewable flowers requiring little strength to process; jute geotextile cloth, harvested from jute flora grown with minimal pesticides, breaks down in 6–12 months with no microplastics, making it ideal for riverbank stabilization for the duration of native plant increase (its excessive tensile power holds soil whilst flora root, then decomposes to enrich earth), coir geotextile (made from coconut husk waste, a meals enterprise byproduct) retains water properly and resists rot for 2–3 years, suiting inexperienced roofs or rain gardens to assist seed germination and add natural count as it degrades, and hemp geotextile, which grows shortly with little water and no pesticides, is greater long lasting than jute (lasting 3–5 years) and works for sustainable landscaping like backyard mattress edging or transient direction reinforcement.

Recycled Synthetic Fibers: For Long-Lasting Green Infrastructure

For everlasting or high-stress inexperienced tasks (e.g., sustainable roads, stormwater systems), recycled synthetic geotextile balances sturdiness with eco-friendliness by means of repurposing waste; recycled PET geotextile cloth, made from post-consumer plastic bottles (PET), diverts plastic from oceans and landfills, resists UV rays, chemicals, and moisture (ideal for permeable pavements or stormwater filters), and main manufacturers use low-energy recycling methods to reduce its carbon footprint by means of 30–40% vs. virgin PET geotextile, whilst recycled polypropylene (PP) geotextile, repurposed from industrial plastic scrap (e.g., ancient packaging), gives excessive tensile energy for soil reinforcement in eco-friendly housing foundations and is lightweight, lowering transportation emissions all through delivery.

2. Low-Carbon Production: Minimizing the Footprint of Geotextile Manufacturing

Even sustainable substances lose their eco-cred if made with energy-intensive or polluting processes. Eco-friendly geotextile cloth manufacturers prioritize practices that reduce emissions, water use, and chemical waste.

Renewable Energy-Powered Factories

Top sustainable geotextile manufacturers strength manufacturing with solar, wind, or hydroelectric strength as a substitute of fossil fuels; for example, a North American producer of recycled PET geotextile makes use of one hundred percent photo voltaic power for extrusion (the procedure that turns plastic into geotextile fibers), slashing its carbon emissions by using 50% in contrast to typical factories, which aligns with inexperienced projects’ desires of decreasing lifecycle environmental impact.

Water-Saving & Chemical-Free Processing

Traditional geotextile production frequently makes use of heaps of liters of water for cleansing and dyeing plus poisonous chemical substances for durability, however eco-friendly choices keep away from this: for recycled artificial geotextile, dry extrusion eliminates water use totally (unlike wasteful moist processes); for herbal fiber geotextile (e.g., jute), mechanical retting (separating fibers from plant stalks with machines) replaces chemical retting, slicing water use through 60% and stopping poisonous runoff into waterways; and as an alternative of detrimental UV stabilizers or flame retardants, eco-friendly geotextile material makes use of plant-based oils or mineral clay, which meet enterprise requirements (e.g., Oeko-Tex® for safety) and make sure the geotextile doesn’t damage soil or wildlife.

Waste Reduction in Production

Sustainable producers optimize reducing patterns to minimize geotextile scrap, then recycle leftover fabric into new products—for example, coir geotextile offcuts are floor into mulch for inexperienced projects, growing a closed loop—and some additionally provide custom-sized rolls to minimize on-site waste, so initiatives solely use the geotextile material they need.

3. Performance That Matches Sustainability: Eco-Friendly Geotextile That Works

Green initiatives can’t compromise on feature for sustainability. Eco-friendly geotextile is engineered to meet or exceed the overall performance of usual options, with delivered environmental benefits.

Biodegradability for Short-Term Projects

For transient initiatives (e.g., development web page erosion control), biodegradable geotextile material eliminates post-project waste; in contrast to typical plastic geotextile (which lingers in landfills for centuries), jute or coir geotextile breaks down into natural matter, as viewed in a motorway venture in Europe that used biodegradable jute geotextile for erosion manage throughout construction—after eight months, it decomposed completely, decreasing waste through 90% vs. the usage of non-biodegradable geotextile.

Durability for Long-Term Green Infrastructure

For everlasting tasks (e.g., inexperienced roofs, wetland restoration), recycled synthetic geotextile offers longevity; recycled PET geotextile has a lifespan of 15–20 years (same as virgin PET) and resists UV degradation, mold, and soil chemicals, that means fewer replacements (lowering fabric waste and carbon emissions from manufacturing new geotextile), as validated through a inexperienced roof in Singapore that has used recycled PET geotextile for 12 years with no symptoms of wear.

Low Environmental Leachate

Eco-friendly geotextile fabric is examined to make certain it doesn’t launch toxins into soil or water—critical for touchy tasks like ingesting water catchments or wetland restoration; recycled geotextile undergoes leachate checking out (per ASTM D5258) to verify no heavy metals or microplastics seep out, whilst herbal fiber geotextile is inherently non-toxic, making it secure for tasks the place natural world or plant fitness is a priority.

4. Targeted Applications: Choosing the Right Eco-Friendly Geotextile Cloth

Not all eco-friendly geotextile fits each and every inexperienced project. Matching the fabric to your project’s dreams and prerequisites ensures most appropriate overall performance and sustainability.

Ecological Restoration Projects

Riverbank stabilization, reforestation, or wetland reconstruction want geotextile that helps ecosystems, so biodegradable choices are best: coir geotextile fabric retains water to help native grasses develop on riverbanks, then decomposes in 2–3 years (giving vegetation time to anchor soil naturally), whilst jute geotextile resists rot in moist wetland stipulations and doesn’t damage aquatic life, stabilizing soil whilst wetland plant life (e.g., cattails) set up to create a self-sustaining habitat.

Green Building & Landscaping

Green roofs, dwelling walls, and sustainable gardens remember on geotextile for drainage and soil separation, so recycled artificial selections excel here: recycled PET geotextile acts as a filter layer for inexperienced roofs, stopping soil from clogging drainage structures (its 15+ 12 months lifespan fits inexperienced roof components, decreasing maintenance), whilst light-weight recycled PP geotextile fabric helps plant life in residing partitions whilst letting water and vitamins flow—it’s non-toxic for plant fitness and recyclable at the stop of the wall’s life.

Sustainable Infrastructure

Low-impact roads, permeable pavements, and stormwater structures want strong, long lasting geotextile, so recycled artificial options work best: recycled PET geotextile reinforces permeable pavements whilst letting rainwater infiltrate soil (reducing runoff) and resists oil and deicing chemicals, suiting city roads, whilst recycled PP geotextile fabric traps sediment and pollution in stormwater filters (protecting groundwater) and is long lasting ample for 10+ years of use, plus recyclable afterward.

Conclusion

Eco-friendly geotextile cloth is greater than a “green trend”—it’s a sensible answer for inexperienced tasks that demand each overall performance and environmental responsibility. By prioritizing sustainable substances (natural or recycled), low-carbon production, dependable performance, and focused applications, you can make certain your geotextile choice helps your project’s dreams whilst minimizing damage to the planet. Whether you’re restoring a wetland or constructing a inexperienced roof, eco-friendly geotextile proves that sustainability and feature don’t have to be at the same time exclusive—they can work collectively to create longer-lasting, extra accountable inexperienced spaces.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province