Containment in Wastewater Lagoons: The Durability of Composite Geomembranes in Aggressive Environments

Introduction: The Critical Role of Advanced Lining Systems

Wastewater cure lagoons characterize one of the most difficult environments for containment infrastructure. Exposed to a complicated cocktail of chemicals, organic agents, ultraviolet radiation, and fluctuating temperatures, these services demand lining options that provide exquisite resilience and long-term performance. In this context, Composite Geomembranes have emerged as a premier engineering choice, combining the sturdy impermeability of polymeric membranes with the defensive and reinforcing advantages of geotextile fabrics. This article explores the science and software in the back of these materials, focusing on their demonstrated sturdiness in aggressive wastewater containment scenarios. Understanding the built-in feature of the impermeable geotextile cloth element is key to appreciating the system's success.

The Anatomy of a Superior Barrier: What is a Composite Geomembrane?

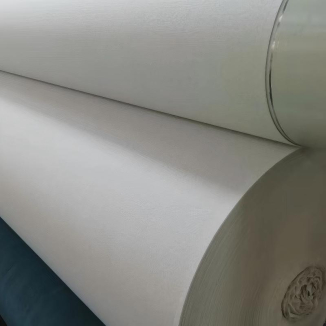

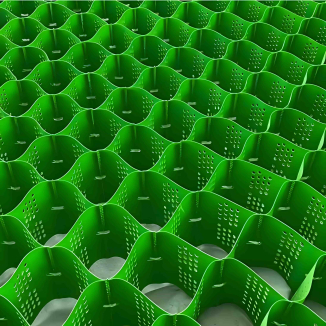

A Composite Geo-membrane is a manufactured multi-layer cloth engineered in particular for fundamental containment applications. Unlike single-ply liners, this gadget usually consists of a bendy geomembrane core laminated to one or greater layers of impermeable geotextile fabric. The geomembrane layer, frequently made from high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), or strengthened polyvinyl chloride (PVC), affords the fundamental hydraulic barrier. Its co-extruded or laminated geotextile backing serves a couple of quintessential functions: it cushions and protects the impermeable movie from puncture for the duration of set up and from subgrade irregularities, enhances interface friction for slope stability, and can supply drainage pathways for gases or minor incidental liquids.

This hybrid sketch takes concept from the established overall performance of Landfill Composite Geomembrane systems, the place comparable challenges from aggressive leachate and long-term steadiness are paramount. The synergy between layers outcomes in a product whose overall performance exceeds the sum of its parts, presenting a tailor-made answer for the harsh prerequisites of wastewater lagoons.

Why Wastewater Lagoons are "Aggressive Environments"

The time period "aggressive environment" in wastewater containment refers to the multifaceted stresses imposed on lining materials. Key elements include:

Chemical Attack: Lagoon contents can differ widely, containing acids, alkalis, hydrocarbons, solvents, and high-salinity brines from industrial processes, all of which can degrade sure polymers.

Biological Activity: Bacteria, algae, and fungi can produce acidic byproducts or bodily connect to surfaces, probably main to biodegradation or biofilm-induced damage.

Thermal Fluctuations: Daily and seasonal temperature cycles motive enlargement and contraction, main to stress on seams and anchored points.

UV Exposure: For uncovered liners, ultraviolet radiation can motive oxidation and embrittlement in unprotected materials.

Physical Stresses: These consist of hydraulic stress from the liquid head, subgrade settlement, and achievable puncture from the subgrade or set up activities.

A standalone geomembrane may succumb to stress cracking, chemical swelling, or puncture over time. This is the place the Composite Geomembrane layout proves its worth, as the built-in impermeable geotextile material acts as a sacrificial armor, dissipating factor stresses and defending the sealing layer.

The Durability Advantage: How Composite Geomembranes Withstand the Assault

The incredible carrier lifestyles of a Composite Geo-membrane in wastewater purposes stems from its layered protection strategy:

Enhanced Puncture and Tear Resistance: The geotextile layer distributes localized stresses from sharp subgrade particles or rocks. This dramatically reduces the threat of installational harm and long-term puncture, a frequent failure mode in harsh environments. This precept is at once tailored from Landfill Composite Geomembrane technology, the place puncture resistance is non-negotiable.

Improved Chemical Resistance: While the polymeric movie is chosen for its chemical compatibility, the geotextile layer provides a protecting buffer. It can stop direct, extended contact between the membrane and centred aggressive factors that would possibly settle on the lagoon floor.

Reduced Stress Cracking: By cushioning the geomembrane from subgrade irregularities and absorbing shear forces, the composite shape minimizes the induction of long-term tensile stresses that can lead to environmental stress cracking (ESC).

Increased Interface Shear Strength: The textured floor furnished by means of the material will increase friction in opposition to adjoining soils or geosynthetics. This is vital for retaining balance on lagoon slopes, specifically beneath variable water levels.

UV Stabilization: High-quality composite liners comprise carbon black or different UV stabilizers into the geomembrane layer, and the material layer can grant extra shading, appreciably slowing photo-oxidative degradation.

The use of a strong impermeable geotextile cloth is consequently no longer an add-on however a core factor of the sturdiness equation, making sure the major barrier stays intact and practical for decades.

Design and Installation: Maximizing Performance in the Field

Specifying a Composite Geomembrane is solely the first step. Its long-term sturdiness hinges on acceptable sketch and meticulous installation.

Site-Specific Material Selection: The preference of polymer (e.g., HDPE for huge chemical resistance, LLDPE for flexibility, fPP for sure organics) and the weight/type of the bonded geotextile have to suit the precise wastewater chemistry and subgrade conditions.

Subgrade Preparation: A smooth, compacted subgrade free of sharp protrusions stays essential. The Composite Geo-membrane is forgiving, however perfect guidance prevents excessive deformation of the composite system.

Seaming Integrity: Field seams, commonly made by using dual-hot wedge fusion, should be completed with precision. The seam ought to bond the geomembrane layers effectively; the geotextile backing is no longer fused however overlapped. Quality assurance trying out (e.g., air pressure, vacuum, or ultrasonic testing) is critical.

Anchorage and Cover: Proper anchorage in perimeter trenches and, the place applicable, the use of shielding cowl layers or ballast in addition guard the system. The layout regularly mirrors pleasant practices developed for Landfill Composite Geomembrane installations, the place regulatory compliance and long-term integrity are fastidiously enforced.

Conclusion: A Sustainable Investment for Long-Term Containment

In the face of escalating environmental rules and the fundamental to defend groundwater resources, the integrity of wastewater containment lagoons can't be left to chance. Composite Geomembranes symbolize a sophisticated, engineered answer born from a long time of journey in annoying purposes like landfill lining. By integrating a protecting impermeable geotextile material at once with a high-performance polymeric barrier, this technological know-how grants unmatched sturdiness in opposition to chemical, biological, and bodily degradation.

For engineers and asset proprietors tasked with designing or refurbishing wastewater lagoons, specifying a Landfill Composite Geomembrane-grade answer ensures a robust, reliable, and long-lasting containment system. It transforms the lagoon from a plausible legal responsibility into a managed, sustainable asset, safeguarding the surroundings whilst imparting peace of thought for the lifecycle of the facility. The Composite Geo-membrane stands as a testomony to superior substances engineering, imparting a definitive reply to the assignment of containment in aggressive environments.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province