Stabilizing Soft Ground: Using Geocells for Road and Pavement Construction on Weak Subgrades

Introduction: The Universal Challenge of Weak Subgrades

Every civil engineer and development challenge supervisor has confronted it: the daunting prospect of constructing a stable, long-lasting avenue or pavement over soft, compressible, or unstable ground. Weak subgrades—such as clay, silt, peat, or loosely compacted fill—present a essential problem. They lack the critical bearing ability and shear electricity to aid regular pavement structures, main to untimely failure, rutting, cracking, and immoderate settlement. Traditional options like whole soil excavation and substitute or deep piling are regularly prohibitively expensive, time-consuming, and disruptive. Today, a greater efficient, robust, and sustainable answer has end up the enterprise wellknown for such challenges: the engineered use of geocells. This superior mobile confinement machine transforms susceptible soils into a strong, built-in composite layer, unlocking a pathway to profitable and long lasting construction. This strategy is a cornerstone of modern-day geocell eco-friendly construction, minimizing earthworks and virgin fabric use.

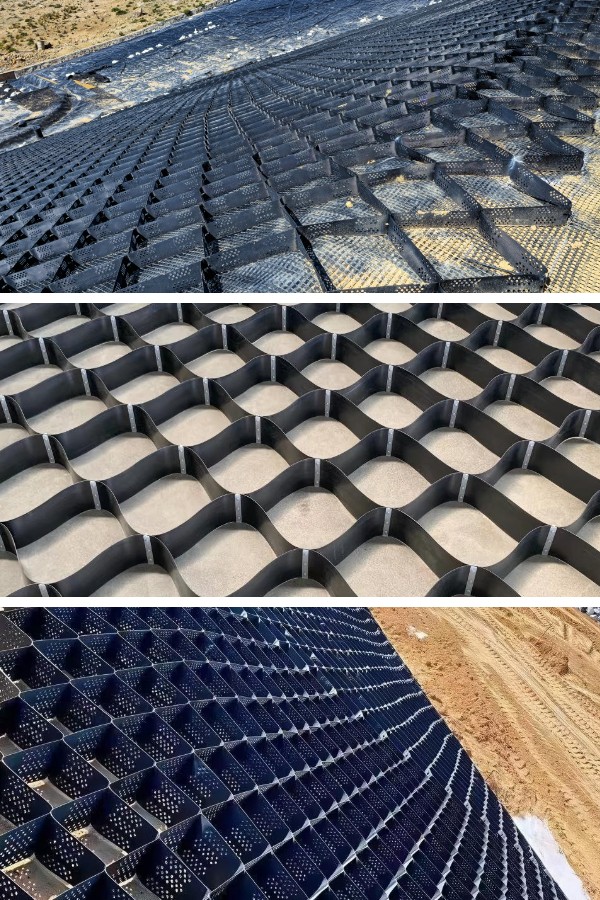

What are Geocells? Understanding the Cellular Confinement Mechanism

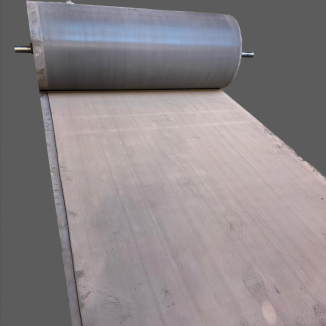

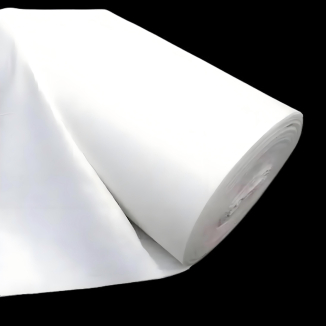

Geocells are three-dimensional, honeycomb-like constructions made from high-density polymer strips welded or woven collectively at normal intervals. When extended on-site, they shape a bendy but inflexible mattress of interconnected cells. These cells are then infilled with domestically handy granular material—crushed rock, sand, or even stabilized soil.

The genius of the gadget lies in confinement. Once infilled and compacted, the phone partitions lock the particles in location via lateral restraint. This action:

Prevents Lateral Movement: Infill cloth can't shift sideways below load, doing away with one of the essential reasons of base path failure.

Distributes Loads Vertically: Applied masses (from vehicles) are unfold over a wider vicinity of the vulnerable subgrade, considerably decreasing the vertical stress and stopping bearing potential failure.

Creates a Stiff Mattress: The composite layer acts as a semi-rigid slab, bridging over neighborhood gentle spots and supplying a uniform, steady platform for the overlying pavement layers.

This creates a reinforced, engineered geocell basis that is basically one-of-a-kind from and most excellent to a traditional unconfined granular layer. The device turns problematic, low-quality infill into high-performing structural material.

Key Applications in Road and Pavement Projects

1. Building Roads and Highways over Soft Soil

This is the quintessential application. By putting in a geocell mattress at the base of the pavement structure, engineers can extensively limit the required thickness of imported aggregate. The geocell layer efficaciously will increase the modulus (stiffness) of the base, making sure that site visitors masses are dissipated earlier than accomplishing the susceptible subgrade. This consequences in a constructible, low-priced avenue that resists rutting and keeps its profile over time, a crucial consideration for get right of entry to roads, haul roads, and even public highways constructed on difficult terrain.

2. Pavements for Industrial Yards, Ports, and Logistics Hubs

Areas concern to excessive static and dynamic masses from heavy container stacks, forklifts, and steady truck site visitors demand first-rate subgrade support. A geocell basis right here presents the quintessential balance to forestall differential agreement and cracking of inflexible or bendy pavements. Its potential to deal with heavy cyclic hundreds makes it perfect for intermodal yards, loading docks, and storage areas the place failure is now not an option.

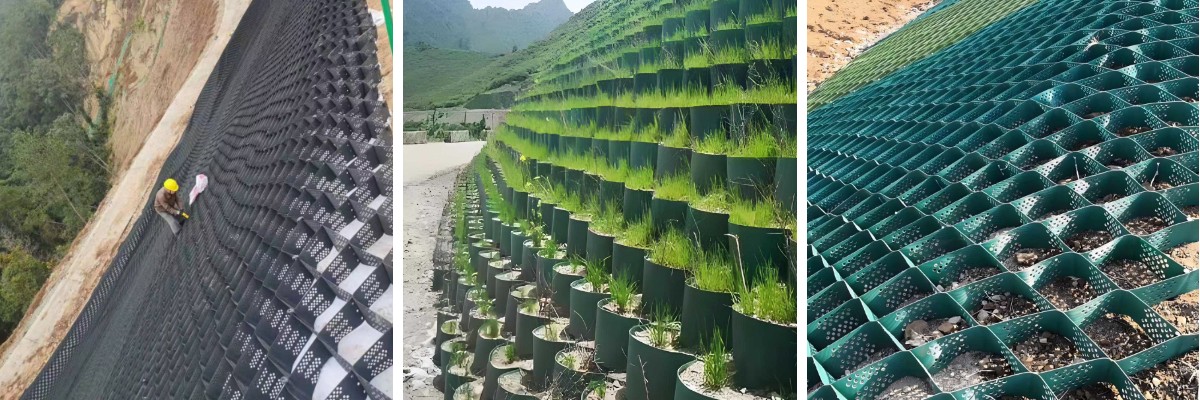

3. Slope Protection and Erosion Control for Embankments and Access Roads

While frequently related with floor erosion control, geocells play a quintessential function in slope safety for developed embankments and cut/fill slopes adjoining to roads. When used to armor a slope face, infilled geocells create a permeable, vegetatable, and extraordinarily steady mat that resists floor runoff erosion and shallow slope failures. This protects the integrity of the road's aiding earthworks. Furthermore, geocells can be used to assemble strengthened slope faces for get right of entry to roads on steep terrain, developing a secure conserving shape that is quicker to construct than usual methods.

The Multifaceted Advantages: Why Choose Geocells?

Unmatched Performance on Weak Soils: Geocells furnish the most nice confinement mechanism for granular infill, supplying most reliable load-distribution and lateral restraint in contrast to different geosynthetics.

Significant Cost Savings: They considerably decrease the extent of expensive, imported notable combination needed. They additionally decrease the depth of soil excavation and disposal, reducing each fabric and hauling costs.

Construction Speed and Simplicity: Installation is rapid and mechanical, requiring much less specialised labor. Projects can development faster, decreasing general timelines.

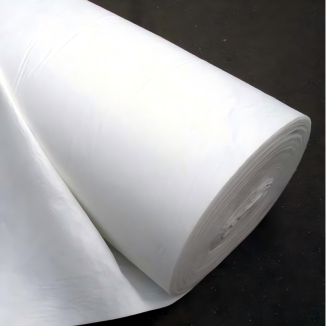

Durability and Long-Term Performance: Made from UV-stabilized, long lasting polymers, geocells furnish a lengthy graph life. The gadget continues its integrity and overall performance over decades, lowering lifecycle protection costs.

**Sustainability and **Geocell Eco-Friendly Construction****: This is a most important benefit. Geocells allow the use of local, frequently marginal on-site soils as infill, minimizing the carbon footprint related with quarrying and transporting big quantities of aggregate. They additionally limit the project's ordinary environmental disturbance.

Design and Installation: A Systematic Approach

Implementing a geocell answer requires cautious planning:

Site and Subgrade Assessment: Understanding the energy (CBR value) and houses of the vulnerable subgrade is vital for design.

Engineering Design: Engineers decide the required depth of the geocell layer, mobile size, polymer strength, and the kind of infill fabric based totally on the ultimate visitors loads.

Subgrade Preparation: The susceptible subgrade need to be graded and minimally compacted to structure a uniform surface.

Geocell Installation: The collapsed panels are multiplied and anchored to the subgrade the use of stakes or pins at specific intervals.

Infilling and Compaction: Cells are stuffed in layers with the certain cloth (e.g., aggregate) and compacted to reap choicest density and interlock.

Conclusion: Building a Stable Future on Unstable Ground

The venture of susceptible subgrades no longer necessitates over-engineered, costly, or environmentally heavy solutions. Geocell technological know-how presents a paradigm shift in geotechnical engineering, offering a smart, efficient, and strong approach for avenue and pavement construction. By growing a effective composite layer—a proper geocell foundation—it turns geological constraints into manageable engineering parameters.

From highways and industrial yards to vital slope safety applications, geocells supply established performance, fee savings, and accelerated construction. Perhaps most importantly, they align flawlessly with the standards of sustainable development, championing geocell eco-friendly building by means of maximizing the use of nearby sources and minimizing environmental impact. For any challenge going through the predicament of smooth ground, geocells stand out as the intelligent, durable, and cost-efficient preference for stabilization and long-term success.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province