Concrete Canvas Roll

1. Convenient construction: It can be flexibly cut and laid, rolled and easy to transport, cured by watering, suitable for complex environments, and does not require complex templates.

2. Controllable solidification: It can be shaped within 2 hours and reach 80% strength within 24 hours. The formula can be adjusted to greatly shorten the construction period.

3. Environmentally friendly and durable: The material usage is 95% less than conventional concrete, with low alkali and low pollution; Fiber reinforced crack resistance, strength up to C25, corrosion resistance and aging resistance, service life about 50 years.

4. Safety adaptation: Processed with basic waterproofing, good flame retardancy, and low smoke; Suitable for complex shapes, can be cut freely, and adaptable to various types of projects.

Product Introduction

Basic Attributes

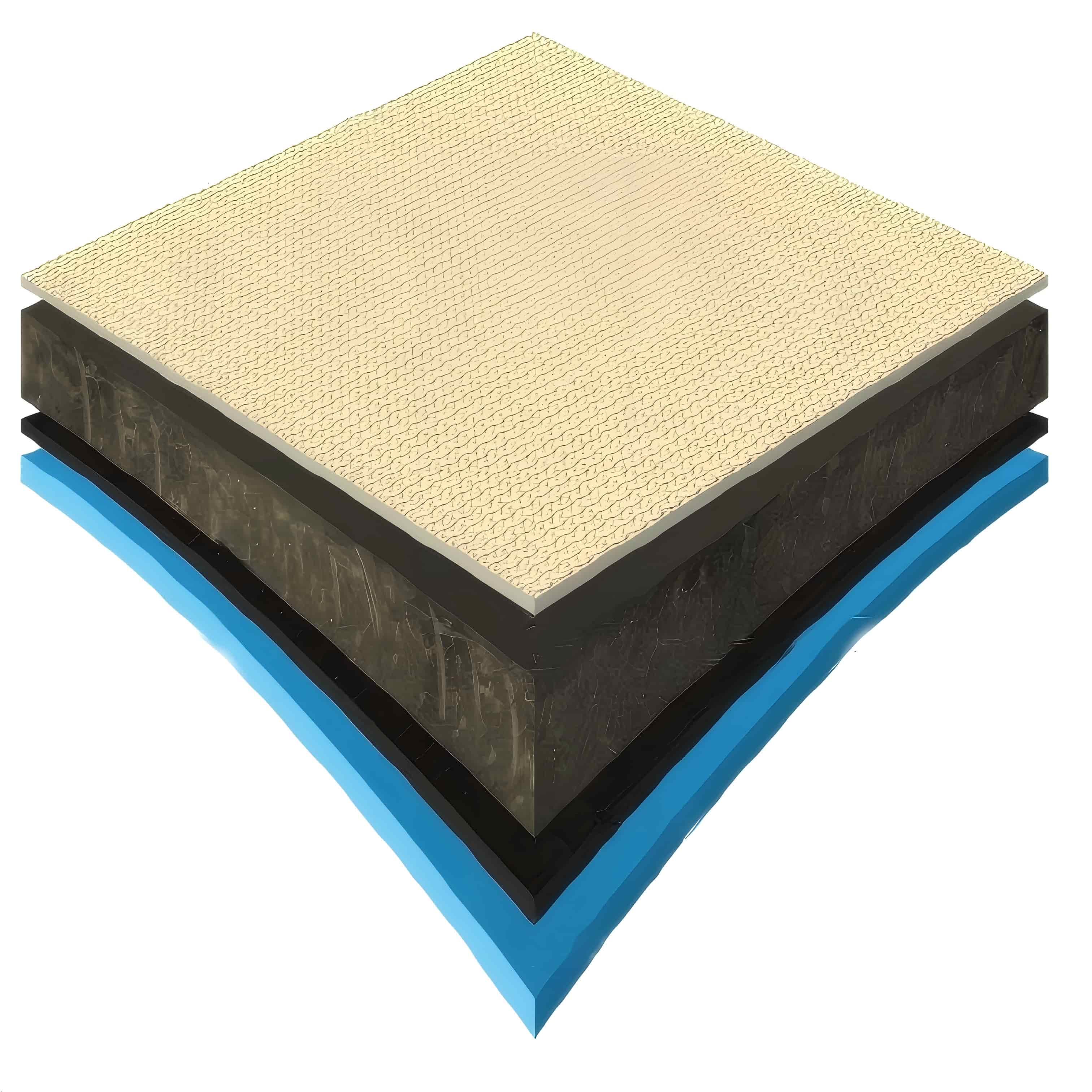

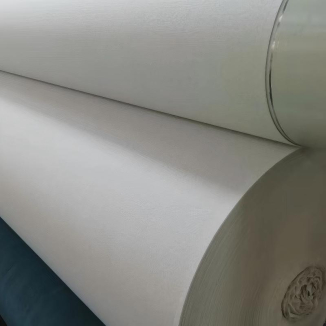

Concrete Canvas Roll is a flexible fabric product made of high-strength fibers as the skeleton, uniformly impregnated with special cement-based materials, and provided in a roll like sealed packaging. Its texture is soft and has a certain degree of toughness. Before curing, it can be flexibly cut, folded, and laid like ordinary fabric. Due to its roll design, the weight of each roll is moderate, making it easy for manual manual loading and unloading as well as short distance handling. Even in difficult to reach construction sites such as mountainous areas and wilderness, it can be easily transported to its destination. The material is processed through multiple special processes, and the continuous fiber reinforced structure inside is evenly distributed. After curing, the overall strength can reach the C25 concrete standard, which can meet the structural strength requirements of most small and medium-sized projects.

Core Functions

Its core function is to rapidly undergo hydration reaction upon contact with water, gradually hardening the soft fabric into a concrete layer with certain strength within a few hours. Through this feature, rapid hardening treatment can be achieved on various foundation surfaces, providing a stable protective layer for structures such as slopes, channels, and pipelines, effectively resisting damage such as rainwater erosion and external impact. At the same time, the cured material can tightly adhere to the surface of the base layer, forming a continuous and complete protective layer, which can prevent soil erosion in slope protection engineering, improve surface wear resistance in hardening engineering, and block water infiltration paths through the compactness of the material itself in waterproof scenarios.

Main Features

Outstanding construction convenience

There is no need to build the templates and support systems required for traditional concrete construction. During on-site construction, only watering or allowing the canvas to naturally absorb water after laying can trigger the curing reaction. Even in complex environments such as underwater, wet and muddy conditions, normal construction can be carried out, greatly reducing the requirements for construction conditions.

Controllable and adjustable solidification speed

Within 2 hours after watering, it remains in a plastic state and can be finely adjusted in shape and size; The hardening strength can reach 80% of the design strength within 24 hours, meeting the initial usage requirements. By adjusting the formula ratio of cement-based materials, rapid solidification (suitable for emergency repairs) or delayed solidification (convenient for complex modeling construction) can be achieved, significantly shortening the overall project duration.

Environmental protection and durability

Compared with conventional concrete, the material usage can be reduced by up to 95% under the same protective area, greatly reducing raw material consumption and transportation costs. The alkali content in the material is strictly controlled, resulting in minimal dust pollution during construction and minimal impact on the surrounding ecological environment. The internal fiber network can effectively suppress cracking problems after curing, and has excellent acid, alkali, and weathering resistance. It is not easily degraded by ultraviolet radiation in natural environments and has a service life of about 50 years.

Strong safety performance and adaptability

After special process optimization, it has good basic waterproof performance and can block shallow water infiltration; The material itself does not support combustion, emits less smoke during combustion, and produces low concentrations of toxic and harmful gases, which meets safety and environmental protection requirements. Due to its good drape and ductility before solidification, it can closely follow the complex surface shape of the covered object, and even form special structures such as hyperbolic surfaces. It can be easily cut with ordinary hand tools and is suitable for various engineering needs such as slope reinforcement, site hardening, pipeline anti-corrosion, emergency water blocking, etc.

Product Parameters

surveillance project | DYSNT-A1 | DYSNT-B1 | DYSNT-C1 | Test basis | remarks |

length (M) | 10--50 | / | |||

width (M) | 1--3 | / | |||

thickness (mm) | 6mm/8mm/9mm/10mm/12mm/15mm/20mm | / | |||

Compressive strength (MPa) | ≧50 | ≧70 | ≧85 | GB/T17671-2021 | |

Flexural strength (MPa) | ≧13 | ≧18 | ≧22 | GB/T 7019-2014 | |

Flexural strength retention rate after freeze-thaw cycles (%) | ≧85% | ≧90% | ≧90% | GB/T 50082-2009 | The freezing and thawing cycle from 50 to 200 times changed the indexes accordingly |

Water quality requirements for hydration | running water | Tap water, sea water | Tap water, seawater, sewage | / | |

Construction temperature conditions | · Construction above 0℃ | · Construction above-5℃ | · Construction above-5℃ | / | |

fire protecting performance | B1 | GB 8624-2012 | |||

Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||

Copper (total copper) (mg/L) | ≤100 | ||||

Zinc (total zinc) (mg/L) | ≤100 | ||||

Cadmium (total) (mg/L) | ≤1 | ||||

Lead (total lead) (mg/L) | ≤5 | ||||

Total chromium (mg/L) | ≤15 | ||||

Nickel (total nickel) | ≤5 | ||||

Arsenic (total) | ≤5 | ||||

Product Application

Slope protection engineering

Concrete canvas rolls exhibit significant advantages in slope protection in mountainous areas, on both sides of highways, and along riverbanks. Due to its excellent drape and extensibility before solidification, it can closely adhere to the complex terrain of slopes, and can be smoothly laid on gentle slopes, steep slopes, or uneven slopes. After laying, watering and solidification can quickly form a continuous and complete concrete protective layer, effectively resisting rainwater erosion and water flow erosion, preventing slope collapse and soil erosion. The internal fiber-reinforced structure can also enhance the overall stability of slopes, reduce landslide risks, and is particularly suitable for slope protection projects in mountainous areas with complex geological conditions and inconvenient transportation.

Site hardening project

For temporary sites, rural roads, warehouse floors, and other scenarios that require rapid hardening, concrete canvas rolls are an ideal choice. It can be flexibly cut according to the size of the site, and the laying process does not require complex templates, which can be easily completed manually. After watering and curing, the strength can reach 80% of the design strength within 24 hours, and it can be put into use in a short period of time, greatly shortening the construction period of site hardening. The cured surface has good wear resistance and compression resistance, which can meet the daily needs of vehicle driving, cargo stacking, etc., and has less dust pollution during the construction process, with minimal impact on the surrounding environment. It is particularly suitable for site hardening projects that require high construction efficiency and environmental protection.

Pipeline protection engineering

Concrete canvas rolls play an important role in the anti-corrosion and impact protection of underground pipelines, water pipelines, and industrial pipelines. It can tightly wrap around the surface of the pipeline, adapt to the circular curved structure of the pipeline, and form a strong protective layer through watering and solidification, effectively isolating corrosive substances in the soil from corroding the pipeline, while resisting external soil pressure and mechanical impact damage to the pipeline. It has excellent acid and alkali resistance and weathering resistance, which can protect pipelines from the influence of natural and industrial environments for a long time, prolong the service life of pipelines, reduce pipeline maintenance costs, and is particularly suitable for pipeline protection engineering in chemical, water conservancy and other fields.

Emergency engineering field

The advantages of concrete canvas rolls are particularly prominent in emergency projects such as flood disaster water blocking, road repair, and temporary cofferdams. The roll design makes it easy to transport and deploy quickly. In emergency situations, it can be manually laid to the desired location and solidified into shape by watering or using on-site water sources. It can solidify normally underwater and quickly construct temporary water retaining walls or cofferdams to prevent the spread of floods; In road repair, it can quickly harden damaged road surfaces and restore road traffic capacity. Its solidification speed is controllable, and a fast solidification formula can be selected according to emergency needs to meet the time requirements of emergency projects and save valuable time for emergency rescue.

Concrete canvas rolls play an important role in various fields such as slope protection, site hardening, pipeline protection, and emergency engineering due to their convenient construction, fast and controllable solidification, environmental friendliness, durability, and strong adaptability. Whether it is long-term protection in complex terrain or rapid response in emergency scenarios, it can meet engineering needs in an efficient and environmentally friendly manner, effectively reducing construction difficulty and costs, while ensuring the stability and durability of the project, demonstrating a wide range of application value and potential.