Filter Fabric under Pavers

1. Reinforcement function: disperses loads, evenly spreads concentrated stresses, and improves the stability and bearing capacity of the soil.

2. Isolation function: Isolate soil layers of different properties to prevent them from mixing with each other, maintain their respective structures and properties, and thus improve the quality of the project.

3. Filtering function: While allowing water to pass through, it prevents the loss of small soil particles with water, prevents piping and soil erosion, and protects the stability of the structure.

4. Drainage function: Forming drainage channels in its planar direction, which can collect and discharge excess water in the soil, accelerating soil consolidation.

Product Introduction:

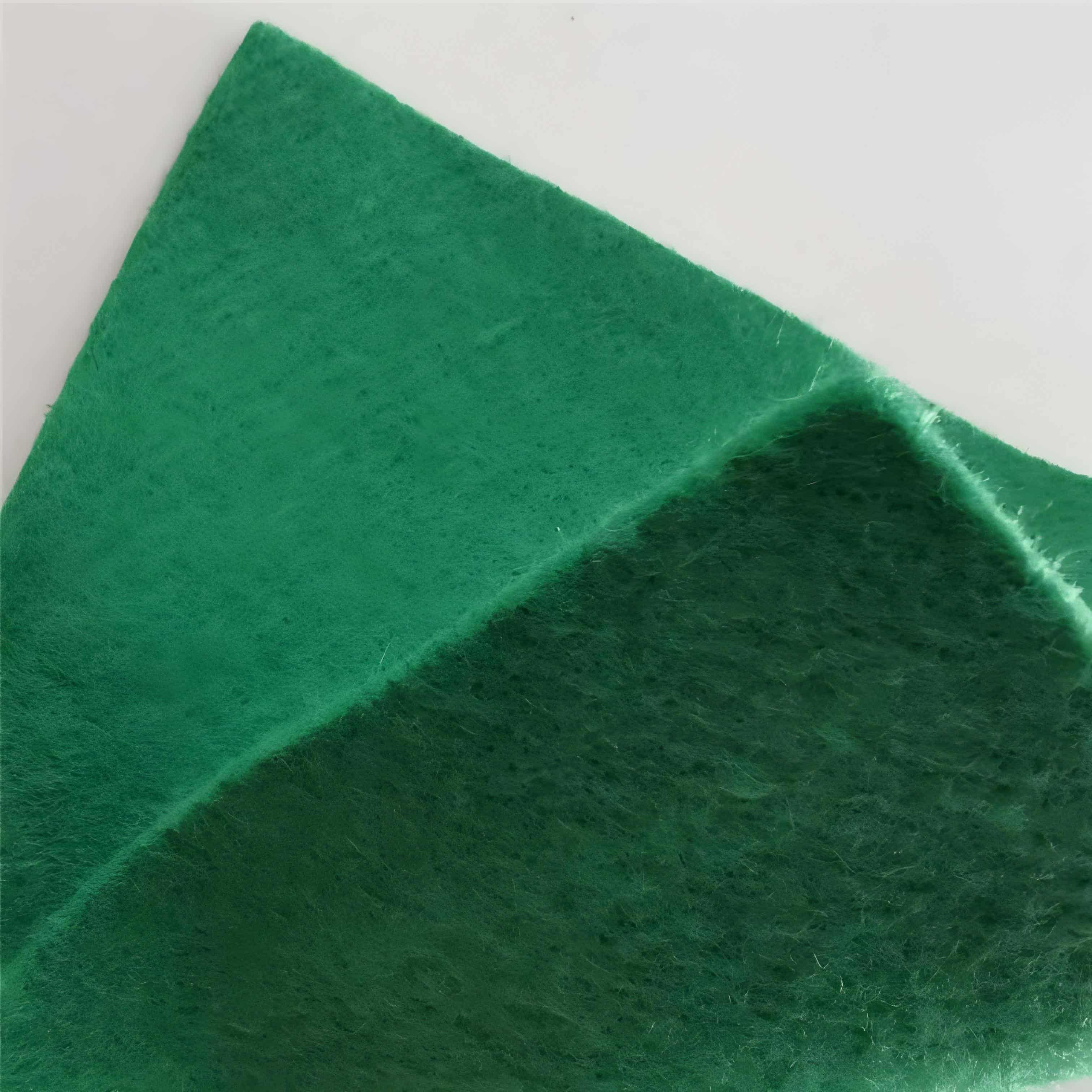

Filter Fabric under Pavers is a permeable geosynthetic material made from synthetic fibers (such as polypropylene, polyester, nylon, etc.) through processes such as needle punching or weaving.

It is essentially "cloth used in civil engineering", usually in the form of a roll, with a width of 1-8 meters and a length of 20-100 meters. Although it looks like ordinary cloth, its raw materials and production process are specially designed for engineering applications, making it have excellent properties such as high strength, corrosion resistance, aging resistance, etc., and it is one of the indispensable basic materials in modern civil engineering.

Feature

The reason why geotextiles are widely used is due to their following core characteristics:

1. Excellent mechanical properties: It has high tensile, tear, burst, and puncture strength, and can work under various complex stress conditions while maintaining structural integrity.

2. Excellent permeability: There are numerous pores between the fibers, allowing water to pass smoothly while effectively preventing excessive loss of soil particles, achieving the function of "permeable but impermeable soil".

3. Corrosion resistance and chemical resistance: Made of chemically synthesized fibers, it can withstand the erosion of common chemical substances in soil, resist mold, not afraid of insect infestation, and has a long service life.

4. Flexibility and adaptability: With good flexibility, it can adapt to uneven settlement in different terrains, tightly bond with the soil, and work together.

5. Easy construction: Light weight, roll supply, transportation, and on-site laying are all very convenient, which can greatly improve construction efficiency and reduce labor intensity.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy engineering: solving the problem of "infiltration+protection"

Dam seepage prevention and filtration: laying anti-seepage geotextile (such as composite geomembrane) on the upstream slope of the dam to prevent water infiltration; Laying filter type geotextile on the back slope to prevent soil loss with seepage (i.e. "reverse filtration"), and to avoid dam piping and collapse.

River regulation: After laying geotextile on the slope of the river, cover it with soil or stone to protect the slope soil from being washed away by water flow, and allow groundwater infiltration to maintain the ecological balance of the river.

Reservoir/artificial lake: Used in combination with geomembrane to enhance anti-seepage effect, while geotextile can protect the geomembrane from being punctured by sharp stones.

2. Traffic engineering: solving the problem of "reinforcement+stability"

Highway/railway subgrade: Lay reinforced woven geotextile at the bottom of the subgrade (soft soil foundation area) to disperse vehicle loads, reduce subgrade settlement and uneven deformation, and avoid pavement cracking; Laying isolation geotextile between the roadbed and pavement to prevent soil particles from infiltrating the asphalt layer and extend the service life of the pavement.

Tunnel engineering: Geotextile is laid between the initial support (anchor spraying) and the secondary lining of the tunnel as a "drainage layer" to guide water seepage from the tunnel wall to the drainage pipe and prevent lining water seepage.

Airport runway: High tensile geotextile is laid between the runway base and cushion layer to enhance the stability of the base and resist the impact load of aircraft takeoff and landing.

3. Construction and municipal engineering: solving the problem of "isolation+environmental protection"

Excavation drainage: Filter geotextile is laid around the excavation slope or dewatering well, wrapped with crushed stone filter layer to prevent sediment from blocking the drainage pipeline and ensure the dewatering effect.

Landfill site: as a protective layer of the "anti-seepage system" - laying geotextile under the HDPE anti-seepage membrane to prevent sharp objects in the soil from puncturing the membrane body; Lay geotextile above the membrane to protect it from damage caused by garbage compaction machinery, while guiding the collection of leachate.

Roof greening/underground garage roof: Lay geotextile above the waterproof layer as an "isolation layer" to prevent root systems in the planting soil from puncturing the waterproof layer, while allowing excess moisture to penetrate into the drainage layer.

4. Agriculture and Ecological Engineering: Solving the Problem of "Water Conservation+Protection"

Agricultural water conservancy: Laying geotextile on the slope of irrigation channels to prevent channel erosion and collapse, and reduce water resource leakage losses; In the improvement of saline alkali land, geotextiles are laid to isolate the saline alkali soil from the cultivated layer and prevent the upward movement of salt.

Slope ecological restoration: In the ecological restoration of mine slopes and road slopes, geotextile is first laid to fix the surface soil, and then grass seeds are sprayed. Geotextile can prevent soil erosion and provide a stable environment for grass seed germination.

In summary, with the advantages of "multifunctionality, low cost, and high efficiency", geotextiles have been upgraded from auxiliary materials to "core functional materials" for modern engineering. Their application scenarios are still expanding into emerging fields such as environmental protection and ecological restoration, becoming an important support for promoting the development of engineering construction towards "green, lightweight, and efficient".