8 oz Geotextile

1. Cost and lifespan advantages: Compared to traditional materials such as sand and gravel layers, the unit area cost is low, and there is no need for frequent maintenance, significantly reducing overall costs;

2. Advantages of convenient construction: lightweight texture, rollable transportation, construction only requires splicing, no need for large equipment, high efficiency, and can adapt to harsh construction environments such as high and low temperatures and humidity;

3. Environmental and sustainable advantages: using more recyclable materials, the production energy consumption is 60% lower than that of cement products, and it can also reduce sand and gravel mining, protecting the ecological environment

Product Introduction:

8 oz Geotextile is a new type of geotechnical material, which is made of synthetic fibers (such as polypropylene, polyester, polyethylene, etc.) or natural fibers (such as cotton, hemp, etc., which are less commonly used) as raw materials. It is a permeable geosynthetic material made through processes such as needle punching, weaving, thermal bonding, and chemical bonding. It mainly undertakes functions such as filtration, drainage, isolation, reinforcement, and protection in fields such as geotechnical engineering, water conservancy engineering, and transportation engineering. It is one of the indispensable key materials in modern engineering construction.

Core Features

The characteristics of geotextile are determined by its raw materials and processes, mainly reflected in the three dimensions of physics, mechanics, and chemistry:

1. Physical characteristics

Controllable permeability: The porosity is usually 30% -90%, and the permeability coefficient can be adjusted according to demand (10 ⁻³ -10 ⁻¹ cm/s), which can both drain and filter;

Lightweight: The unit area weight (gram weight) is generally 100-800g/㎡, which is more than 80% lighter than traditional sand and gravel filter layers, making it easy to transport and construct;

Good flexibility: can adapt to complex terrains (such as steep slopes and curved foundations), is not easily damaged after bending or folding, and has a high degree of fit.

2. Mechanical characteristics

High tensile strength: The longitudinal/transverse tensile strength can reach 5-50kN/m, which can withstand the tensile force generated by soil deformation and avoid cracking;

Strong tear/puncture resistance: When facing crushed stones or mechanical compaction during construction, it is not easily torn or punctured, ensuring structural integrity;

Stable creep performance: When subjected to long-term loads (such as soil pressure), the deformation is small and tends to be stable, without causing engineering failure due to "excessive creep".

3. Chemical characteristics

Excellent corrosion resistance: It has good resistance to acids, bases (pH 3-11), salts, organic solvents, etc., and can last for 10-50 years in environments such as sewage, seawater, and saline alkali land;

Strong anti-aging property: some products are added with anti ultraviolet (UV) and antioxidant, which can resist sun exposure in the open air and slow down aging;

Non toxicity: Geotextiles made from food grade materials such as polypropylene can be used in drinking water engineering and will not release harmful substances to pollute water bodies.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Transportation Engineering

Highway/railway subgrade: laid between the subgrade and the cushion layer, serving to isolate, filter, and drain, prevent the mixing of subgrade soil and gravel, and reduce subgrade settlement (especially in soft soil foundation sections, it can reduce settlement by 30% -50%);

Road maintenance: When renovating old road surfaces, geotextile is laid as a "crack prevention layer" to reduce the reflection cracks caused by old road surface cracks on the new road surface;

Tunnel engineering: used as a drainage layer behind the tunnel lining to discharge water seepage from the surrounding rock and prevent lining cracking or seepage.

2. Water conservancy engineering

Embankment/riverbank anti-seepage: Used in combination with geomembrane to form a "geotextile geomembrane" anti-seepage structure, enhancing the anti-seepage effect while protecting the geomembrane from being pierced by sharp stones;

River/channel slope protection: laid between the slope protection bricks and the soil to filter rainwater, fix the soil, and prevent sediment loss under the slope protection bricks (to avoid slope collapse);

Reservoir/Lake Dredging: Used for "sludge filtration" in dredging projects, separating water and solid particles from sludge, facilitating sludge removal and water resource recovery.

3. Municipal engineering

Wastewater treatment plant: used as a filtration layer for sedimentation tanks and filters, to filter suspended solids in wastewater and improve water quality;

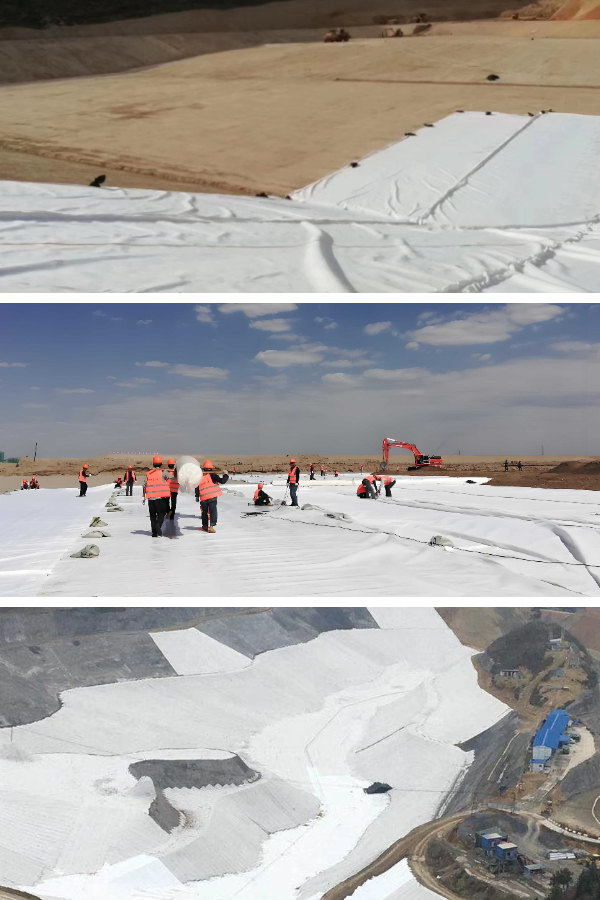

Landfill site: laid at the bottom and periphery of the landfill area, serving as a protective layer for the "anti-seepage layer" (preventing sharp objects from penetrating the anti-seepage membrane), while filtering the leachate (reducing the infiltration of pollutants into groundwater);

Urban greening: used for roof greening and drainage layer of artificial lakes to discharge excess rainwater and prevent plant root rot or water accumulation in artificial lakes.

4. Geotechnical Engineering

Soft soil foundation reinforcement: Composite with geogrid (forming a "geotextile grid" reinforcement structure) to enhance the bearing capacity of soft soil foundation and reduce foundation settlement (such as soft foundation treatment in industrial parks and airport runways);

Slope protection: It is laid on the surface of the slope soil and fixed with anchor rods to prevent landslides or soil erosion of the slope soil (especially in mountainous roads and mining reclamation projects).

5. Other fields

Agricultural engineering: used for anti-seepage and filtration of drainage layers in greenhouses and irrigation channels in farmland;

Environmental protection engineering: used for anti-seepage of tailings ponds and filtration of leachate from solid waste yards;

Military engineering: rapid anti-seepage reinforcement of temporary flood control embankments and emergency rescue projects.

In summary, geotextile has become a key material for improving quality, reducing costs, and increasing efficiency in modern engineering construction due to its advantages of multifunctionality, high cost-effectiveness, and convenient construction. With the development of engineering technology, its application scenarios will also expand to more specialized fields.