HDPE Landfill Liner

1. Excellent anti-seepage performance:This is its most core advantage. Its permeability coefficient is extremely low (usually less than 10 ⁻¹³ m/s), which can effectively prevent the infiltration of fluids such as water, oil, chemicals, biogas, etc., ensuring that the medium does not leak or pollute.

2. Excellent chemical stability:Especially represented by HDPE geomembrane, it can resist corrosion from most acids, alkalis, salts, and organic solvents, and is suitable for harsh environments such as landfills and chemical parks.

3. Excellent aging resistance performance:By adding anti UV agents such as carbon black, geomembranes can resist prolonged exposure to sunlight and extend their service life in outdoor environments, with a design lifespan of over 50 years.

4. Higher mechanical strength:It has good tensile strength, tear resistance, and puncture resistance, and can withstand certain foundation settlement and external loads.

Product Introduction:

HDPE Landfill Liner is a waterproof and barrier material based on high molecular weight polymers, which is widely used in civil engineering. Here is a detailed introduction:

Materials and Classification

Main materials: Commonly used include polyvinyl chloride (PVC), polyethylene (PE), EVA (ethylene/vinyl acetate copolymer), etc. Among them, PE geomembranes are widely used, such as low-density polyethylene (LDPE) geomembranes, high-density polyethylene (HDPE) geomembranes, etc.

Product classification: According to the structure, it can be divided into smooth geomembranes and rough geomembranes; According to the composite situation with non-woven fabric, it can be divided into one fabric and one film, two fabrics and one film, two films and one fabric, etc. According to quality standards, HDPE geomembranes can be divided into ordinary type, standard GH-1 type, urban construction GH-2S type, etc.

Performance Characteristics

Excellent anti-seepage performance: For example, HDPE geomembranes have extremely small pore sizes, with an average pore size as low as micrometers, and can withstand water pressures up to 300kPa without leakage.

Strong corrosion resistance: The inertia and non-polar nature of polymer materials enable them to resist the erosion of corrosive substances such as acids, bases, salts, and organic matter in water. After 20 years of simulated immersion tests in a solution environment with a pH value of 3-11, their physical and chemical properties remain stable.

Good mechanical properties: The unique long-chain macromolecular structure of polymer materials gives them high tensile and puncture resistance, which can withstand soil pressure, water pressure, and other effects, effectively reducing land settlement and deformation.

Strong weather resistance: It has good heat resistance and cold resistance. It can be used in a wide range of ambient temperatures, ranging from -70 ℃ to+110 ℃, and has good aging resistance. It can be exposed for a long time to maintain its performance.

Specifications

Thickness: Generally between 0.2mm-3.0mm, different projects have different thickness requirements. For example, geomembranes with a thickness greater than 1.5mm are usually used for bottom anti-seepage, and geomembranes with a thickness greater than 0.5mm can be used for temporary covering.

Width: The commonly used width is 6m, and 1m-6m can be customized.

Roll length: The standard roll length is 50 meters, but it can also be customized according to customer requirements.

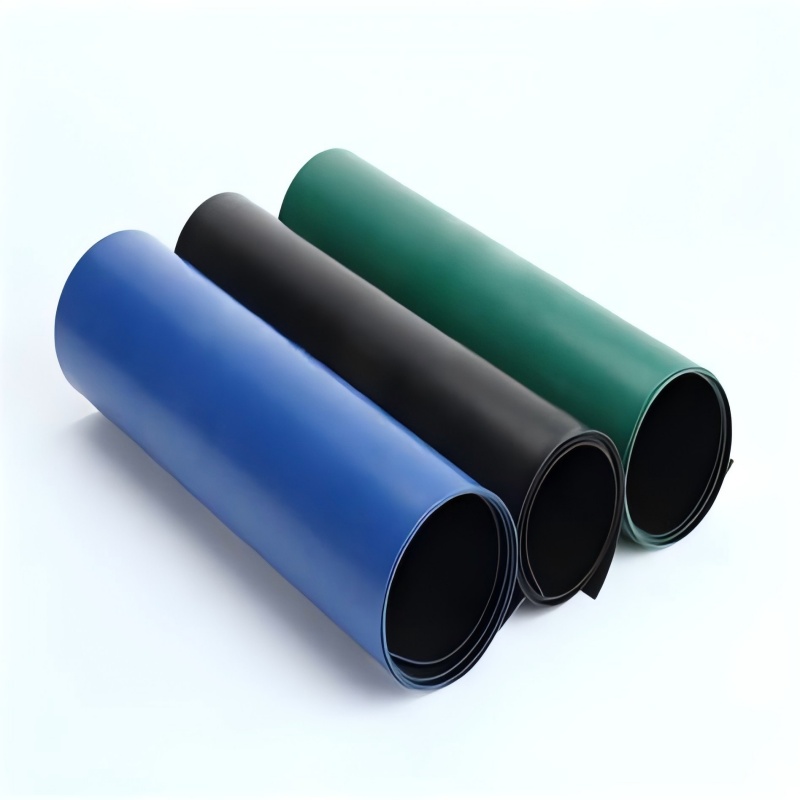

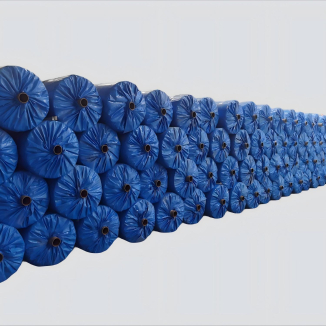

Color: Common colors include black, white, blue, green, etc., and can also be customized according to needs.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

1. Environmental engineering

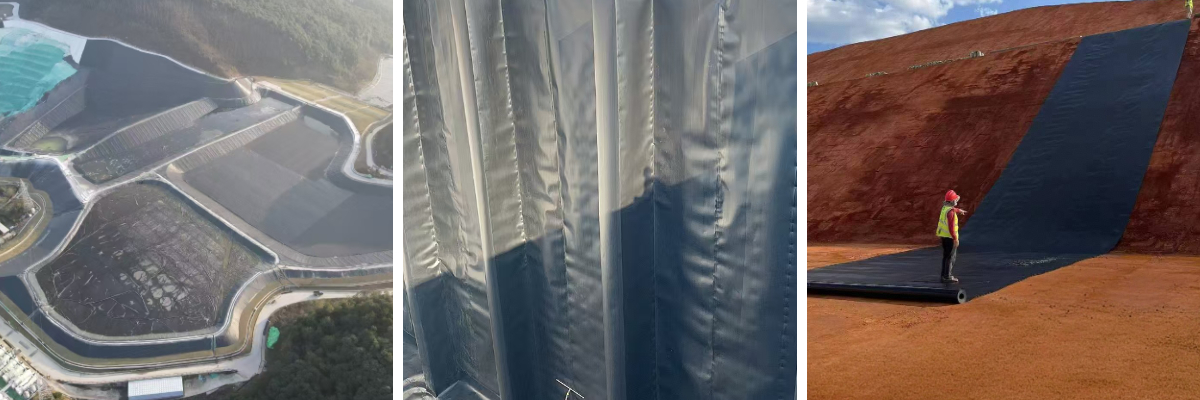

Solid waste landfill (garbage landfill): This is the largest and most classic application of geomembranes. Used for bottom padding and top covering to prevent pollution of groundwater and soil by leachate from garbage, and to collect biogas.

Sewage treatment tank/oxidation pond: used for regulating tanks, sedimentation tanks, anaerobic ponds, etc. in municipal and industrial sewage treatment plants to prevent sewage leakage.

Hazardous waste disposal site: isolate toxic and harmful substances to protect the environment.

2. Water conservancy, hydropower and water resources management

Artificial lakes and landscape water bodies: prevent lake water leakage and maintain water level.

Reservoir and channel lining: reduce water leakage loss during water transportation and improve water resource utilization efficiency.

Anti seepage of dams and embankments: used for the core wall or upstream surface to prevent reservoir water from seeping into the dam body.

3. Mining and Metallurgy

Heap leaching tank: used in the wet smelting of metals such as gold, silver, and copper to lay heap leaching tanks and collect precious metal solutions.

Tailings pond: prevent the leakage of tailings wastewater and heavy metal ions after beneficiation, which pollutes the environment.

Evaporation pond: used in mining and chemical industries to treat wastewater through natural evaporation, with geomembranes preventing its infiltration.

4. Agriculture and Aquaculture

Aquaculture ponds (such as shrimp ponds and fish ponds): Maintain the water level in the pond, prevent water loss, and facilitate pond cleaning and management.

Reservoirs and irrigation channels: Similar to water conservancy applications, they are mainly used for agricultural water-saving irrigation.

5. Construction and Municipal Engineering

Basement and tunnel anti-seepage: as a waterproof layer for the underground part of buildings.

Roof garden waterproofing: providing a reliable waterproof barrier for the roof greening system.

Subway and underground passages: prevent groundwater intrusion.

Geomembranes play an indispensable role in many fields such as environmental protection and sanitation, water conservancy engineering, municipal engineering, landscaping, petrochemical mining, agriculture and aquaculture, transportation facilities, etc. It effectively solves the problem of leakage, protects soil and groundwater, improves the safety and stability of the project, promotes the rational utilization of resources and environmental protection.