Using Composite Geotextiles for Railway Track Bed Stabilization

For railway engineers and infrastructure developers, reaching a stable, durable, and low-maintenance tune mattress is a consistent pursuit. The basis upon which the tracks relaxation is essential to the whole system's overall performance and longevity. In contemporary railway construction, one cloth has revolutionized this foundational layer: the composite geotextile.

This article delves into how these superior geosynthetics work, their key benefits, and why they are turning into an imperative issue in constructing the railways of the future.

What Are Composite Geotextiles and How Do They Function?

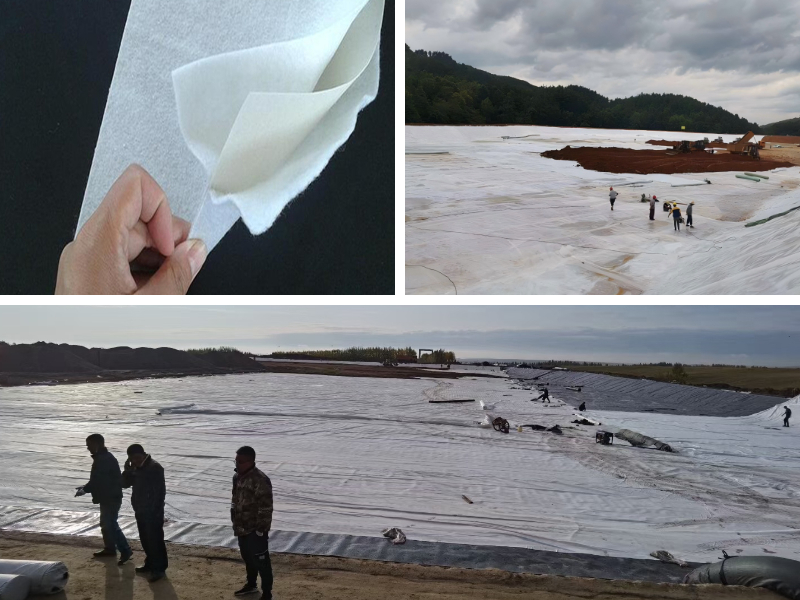

A composite geotextile is an engineered fabric that combines the high-quality residences of two or extra geosynthetic components. Typically, it consists of a geotextile (a fabric-like material) thermally or adhesively bonded to a geomembrane, most in many instances an HDPE composite geomembrane.

This fusion creates a multifunctional product that performs countless imperative roles simultaneously:

●Separation: The geotextile factor prevents the intermixing of the tender subgrade soil beneath with the coarse mixture ballast above. Without this layer, satisfactory soil particles can pump up into the ballast, contaminating it and decreasing its drainage and load-bearing capacity.

●Reinforcement: The material provides tensile electricity to the soil, distributing masses over a wider location and lowering differential settlement.

●Filtration: The geotextile approves water to omit via whilst conserving soil particles, stopping the erosion of the subgrade.

●Impermeable Barrier: This is the key differentiator. The built-in HDPE composite geomembrane layer acts as a strong impermeable geotextile barrier, stopping water from infiltrating the subgrade soil. Water saturation is a essential reason of subgrade softening and failure.

The Critical Role of an Impermeable Geotextile Barrier in Railway Stability

Water is the quantity one enemy of railway song stability. When the subgrade soil underneath the ballast will become saturated, it loses its power and stiffness, main to a host of problems.

The inclusion of an impermeable geotextile layer, particularly the HDPE composite geomembrane inside the composite, addresses this problem head-on. High-Density Polyethylene (HDPE) is famend for its incredible chemical resistance, durability, and very low permeability. By developing a continuous, watertight barrier, the composite geotextile:

●Protects the Subgrade: It shields the underlying soil from floor water infiltration and rising capillary water, keeping its authentic energy and bearing capacity.

●Reduces Frost Heave: In cold climates, a water-saturated subgrade is inclined to frost heave, which creates uneven tune levels. By preserving the soil dry, the impermeable geotextile barrier substantially mitigates this risk.

●Enhances Drainage: With water avoided from coming into from below, the drainage device solely wants to manage floor water and rainfall, making it some distance extra efficient. This maintains the ballast layer dry and functioning optimally.

Key Benefits of Integrating Composite Geotextiles in Railway Projects

The multifunctional nature of a composite geotextile interprets into tangible, long-term advantages for railway tasks of all scales.

1. Extended Service Life and Reduced Maintenance

By stopping ballast infection and subgrade softening, the song geometry stays steady for an awful lot longer. This leads to a dramatic discount in the frequency and price of upkeep things to do like tune leveling, tamping, and ballast replacement. The HDPE composite geomembrane ensures this overall performance is sustained over decades.

2. Improved Load Distribution and Bearing Capacity

The reinforcement characteristic of the composite geotextile approves the music mattress to higher guide dynamic masses from heavy, high-speed trains. It distributes the stress over a wider area, lowering the strain on the vulnerable subgrade and minimizing everlasting deformation. This is vital for heavy-haul freight traces and high-speed passenger corridors.

3. Superior Moisture Management and Erosion Control

The mixture of filtration and impermeability affords unparalleled moisture control. The geotextile facet filters water from the ballast, whilst the impermeable geotextile membrane blocks upward moisture movement. This twin motion protects the structural integrity of the complete music mattress meeting and prevents soil erosion alongside embankments and cuttings.

4. Cost-Effectiveness Over the Project Lifespan

While the preliminary funding in a remarkable composite geotextile may also be greater than common methods, the long-term financial savings are substantial. Reduced upkeep needs, fewer carrier interruptions, and a longer asset lifestyles cycle end result in a considerably decrease complete fee of ownership.

Best Practices for Installing Composite Geotextiles in Railway Construction

Proper set up is paramount to accomplishing the favored overall performance from a composite geotextile.

Site Preparation: The subgrade have to be excellent graded and compacted. All sharp objects, debris, and vegetation have to be eliminated to forestall injury to the material.

Material Placement: Rolls of the composite geotextile are deployed longitudinally alongside the music bed. The facet with the HDPE composite geomembrane have to face downward, in direct contact with the subgrade to structure the impermeable barrier. The geotextile aspect faces upward to interface with the ballast.

Overlapping and Seaming: Adjacent rolls ought to have a enough overlap (as per producer and format specifications). For the impermeable geotextile feature to be continuous, the seams of the geomembrane layer frequently want to be sealed, usually thru thermal or chemical welding, to make certain a whole barrier.

Ballast Placement: The mixture ballast is cautiously positioned on pinnacle of the laid composite geotextile. Initial layers must be positioned gently to keep away from puncturing or displacing the material. Machinery have to now not at once function on the uncovered geotextile.

Conclusion: Building a Stronger Future for Rail with Composite Geotextiles

The challenges of modern-day railway engineering demand revolutionary and strong solutions. The composite geotextile, with its built-in impermeable geotextile layer, represents a substantial soar ahead in song mattress stabilization technology. By combining separation, reinforcement, filtration, and—most importantly—an fantastic moisture barrier by the HDPE composite geomembrane, it offers a holistic protection in opposition to the predominant motives of music degradation.

For any new railway challenge or the rehabilitation of present lines, specifying a high-performance composite geotextile is a verified approach to beautify safety, make sure long-term reliability, and optimize lifecycle costs. It is a foundational funding that paves the way for a smoother, greater resilient, and environment friendly rail network.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province