The Unsung Hero: The Critical Role of Geotextiles in Modern Drainage Systems

Effective drainage is the cornerstone of any rewarding civil engineering, construction, or landscaping project. Without it, water accumulation can lead to catastrophic failures, from eroded slopes to structural damage. At the heart of modern, efficient drainage solutions lies a indispensable component: the geotextile. This engineered fabric is not just an accessory; it is a quintessential component that ensures the longevity and performance of the complete system. This article delves into the critical role of geotextiles in modern drainage, exploring how they work and why they are non-negotiable for sturdiness and function.

What Are Geotextiles? More Than Just Fabric

Before we explore their special use of geotextile in drainage, let's define what they are. Geotextiles are permeable artificial textiles, typically made from polypropylene or polyester. They are designed to interact with soil and rock to provide particular engineering functions such as separation, filtration, drainage, reinforcement, and protection. When it comes to drainage, the integral functions we care about are filtration and separation. Not all geotextiles are created equal, and perception the different geotextile fabric types is the first step in deciding on the right one for your drainage application.

The Core Function: How Geotextiles Make Drainage Systems Work

The essential challenge in any drainage gadget is allowing water to flow freely into and through the drainage mixture or pipe while stopping the surrounding soil from migrating and clogging the system. This is exactly the place a geotextile comes into play.

Imagine a French drain without a filter fabric. Over time, first-rate soil particles would wash into the gravel, turning it into mud and absolutely blockading the passage of water. The drain would fail, necessitating costly excavation and repair. The strategic use of geotextile as a filter fabric prevents this. It acts as a sieve, located between the soil and the drainage aggregate. Water passes through the geotextile's pores, but the soil particles are held back, maintaining the system's excessive permeability and overall performance for decades.

Separation: Ensuring Long-Term System Integrity

Beyond filtration, the separation function is equally vital. In a drainage trench, the geotextile prevents the native soil from mixing with the clean drainage gravel. Without this barrier, the two substances would intermix underneath dynamic loads (like traffic or hydraulic pressure), lowering the drainage attainable and structural stability of the gravel layer. By keeping the layers distinct, the geotextile preserves the graph integrity and universal performance of the drainage system. This is a critical consideration for all geotextile material types, as they have to possess the mechanical electricity to withstand set up stresses and long-term loading without tearing.

Choosing the Champion: Why Non-Woven Geotextiles Dominate in Drainage

While there are a variety of geotextile fabric types, the most normally specified fabric for drainage and filtration applications is the non-woven geotextile. But why is this the case?

Non-woven geotextiles are manufactured via a mechanical or thermal process that randomly entangles synthetic fibers, creating a felt-like, porous fabric. This shape gives them a distinct set of properties best for drainage:

1.High Permittivity: This refers to the ability to allow water to flow thru the fabric plane. The random fiber form of a geotex non woven creates a multitude of interconnected pores that facilitate excellent cross-plane water flow, which is crucial for water to enter a drain from the surrounding soil.

2.Robust Filtration: The tortuous path through the fabric efficaciously traps soil particles while keeping water passage, preventing blinding and clogging.

3.Conformability: Non-woven geotextiles are extraordinarily flexible and can barring difficulty conform to irregular surfaces, making sure intimate contact with the soil without leaving gaps.

While woven geotextiles provide excessive tensile power and are excellent for reinforcement, their greater planar, slit-film shape is much less most effective for the cross-plane water flow required in most drainage scenarios. Therefore, when filtration and drainage are the predominant goals, a geotex non woven is almost continually the finest choice. Understanding this difference between geotextile fabric sorts is vital for specifying the right product.

Key Applications: The Use of Geotextile in Action

The principles of geotextile filtration and separation are utilized across a significant range of drainage projects. Here are some of the most necessary applications the region their role of geotextiles is undeniable.

1. French Drains and Perimeter Drains

This is the traditional application. A trench is lined with a geotex non woven fabric, filled with clean gravel containing a perforated pipe, and then the fabric is wrapped over the pinnacle to fully encapsulate the aggregate. This creates a protected, free-draining channel that efficaciously collects and redirects groundwater.

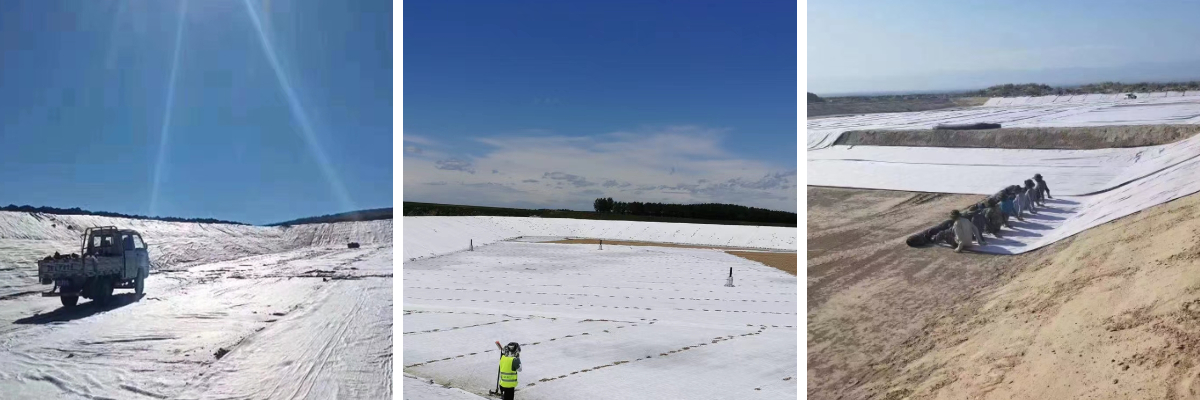

2. Landfill Leachate Systems

In present day landfills, managing leachate (the liquid that percolates thru waste) is a monumental task. Geomembrane liners include the leachate, however it ought to be collected and removed. Here, non-woven geotextiles are used to guard the geomembrane from puncture and to filter the leachate as it flows into the collection pipes, stopping clogging from first-class waste particles.

3. Road and Pavement Edge Drains

Water trapped inside the pavement structure is a major reason of failure. Edge drains, frequently consisting of a perforated pipe surrounded by mixture and wrapped in a geotextile, are established alongside roadways to remove this water. The use of geotextile here is quintessential to stop the infiltration of subgrade soils into the drain, making sure its long-term performance and defending the street investment.

4. Behind Retaining Walls

Retaining walls are beneath regular strain from waterlogged soil. Proper drainage is essential to relieve hydrostatic pressure, which can motive partitions to crack or collapse. A drainage combination layer behind the wall, wrapped in a filter fabric, allows water to drain freely to weeps holes. The choice of sturdy geotextile fabric types for this application is key, as they ought to face up to large backfill pressures.

Specifying the Right Geotextile for Your Drainage Project

Selecting the appropriate geotextile is now not a one-size-fits-all process. Key houses have to be considered primarily primarily primarily based on the soil conditions and project requirements. When planning the use of geotextile for drainage, the most important houses to evaluate are:

1.Apparent Opening Size (AOS): This indicates the approximate largest opening in the fabric. A smaller AOS (e.g., AOS 40-70) is used for fine-grained soils, even as a large AOS (e.g., AOS 30-40) can be used for coarser soils.

2.Permittivity: This is a measure of the fabric's ability to allow water to pass via it. A higher permittivity is generally favored for high-flow drainage applications.

3.Grab Tensile Strength: The cloth must be strong enough to live on installation without ripping or tearing.

Consulting with a licensed engineer or a knowledgeable dealer is always motivated to ensure you are deciding on from the correct geotextile cloth types for your unique soil and hydraulic conditions.

Conclusion: A Small Investment for a Massive Return

The role of geotextiles in current drainage systems can't be overstated. What might show up like a simple sheet of material is, in fact, a highly engineered factor that ensures the durability, efficiency, and success of a multi-thousand-dollar project. By understanding the crucial functions of filtration and separation, and by way of means of specifying the right geotex non woven product for the job, engineers, contractors, and landscapers can prevent high priced screw ups and build infrastructure that stands the take a look at of time. In the world of construction, the small investment in a extremely good geotextile is one of the highest-return selections you can make.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province