Understanding Geocell Tensile Strength and Modulus for Long-Term Performance

Introduction: The Foundation of Reliable Geocell Solutions

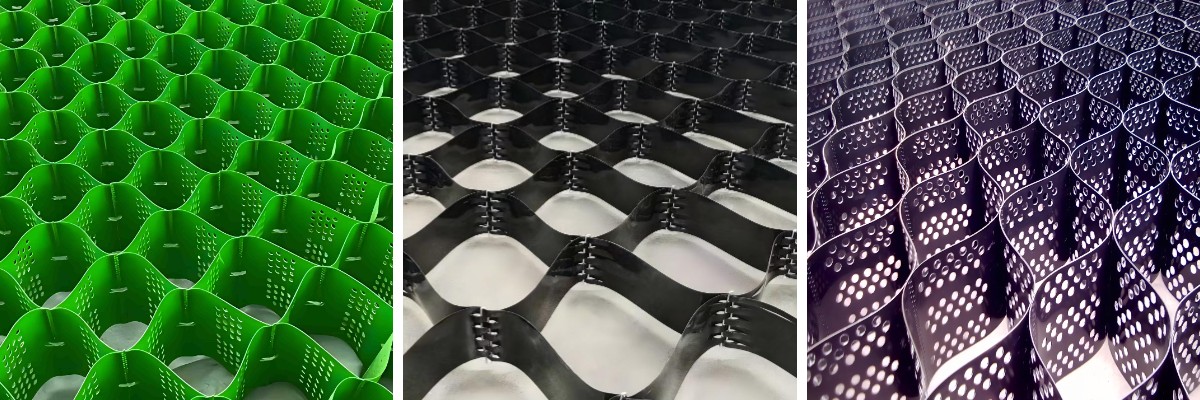

Long-term overall performance in slope stabilization and erosion manage relies upon on two vital mechanical properties: tensile power and modulus. These traits outline how properly geocell options withstand stress, keep shape, and suffer environmental challenges over time. For purposes like motorway embankments, coastal protection, or residential landscaping, geocell slope safety depends on substances engineered to stability flexibility and rigidity—with geocell hdpe (high-density polyethylene) rising as a pinnacle desire for its strong performance. This information breaks down what tensile energy and modulus suggest for geocells, why they count number for long-term reliability, and how to pick out geocell options that supply constant results. Whether you’re designing a large-scale infrastructure challenge or a small erosion manipulate initiative, appreciation these residences is key to heading off untimely failure and making sure lasting stability.

Key Definitions: Tensile Strength and Modulus Explained

To consider geocell options effectively, it’s crucial to make clear the two core houses shaping their performance:

Tensile Strength: Resistance to Pulling Forces

Tensile electricity refers to the most pressure a geocell can stand up to earlier than tearing or breaking when pulled. For geocell slope protection, this property is integral for the duration of set up and all through the project’s lifespan. During installation, geocells are stretched over uneven terrain, anchored at the edges, and crammed with soil or aggregate—all moves that exert pulling stress. Over time, soil movement, temperature fluctuations, and water strain proceed to check the material’s tensile strength. A geocell with insufficient tensile electricity will stretch past its limits, tear at the seams, or collapse, compromising the whole stabilization system.

Modulus: Stiffness and Shape Retention

Modulus (often known as tensile modulus or Young’s modulus) measures a material’s stiffness—how tons it resists deformation beneath stress. Unlike tensile energy (which focuses on breaking point), modulus describes how the geocell behaves earlier than attaining that limit. A high-modulus geocell continues its form beneath load, presenting steady confinement for soil or aggregate. A low-modulus geocell might also stretch excessively, decreasing its potential to assist the fill cloth and shield the slope. For long-term performance, the proper modulus ensures the geocell retains its structural integrity except turning into too inflexible (which leads to cracking) or too bendy (which leads to sagging).

Why Geocell HDPE Excels in Tensile Strength and Modulus

Geocell hdpe is the cloth of desire for disturbing geocell options due to the fact its molecular shape is engineered to optimize each tensile energy and modulus:

Molecular Structure Advantages

HDPE’s linear, dense molecular chains create a cloth that balances flexibility and rigidity. Unlike lower-density plastics, HDPE resists everlasting deformation when stretched, thanks to sturdy intermolecular bonds. This shape offers geocell hdpe excessive tensile electricity to face up to pulling forces and a balanced modulus to keep structure beneath load. For geocell slope protection, this potential the fabric can adapt to minor floor shifts barring tearing whilst offering steady confinement for soil.

Resistance to Environmental Degradation

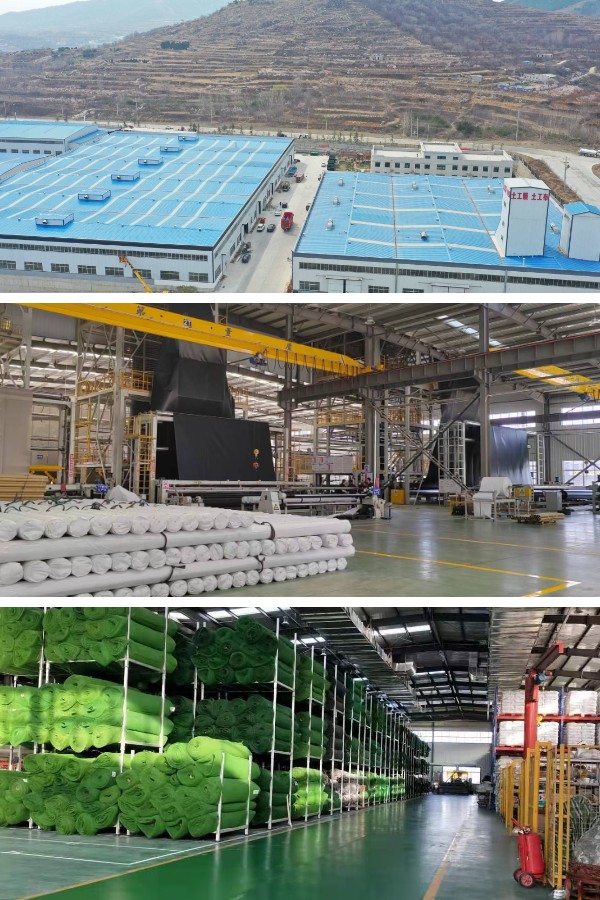

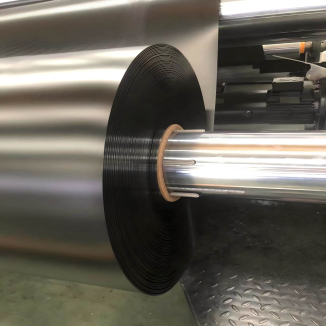

Tensile electricity and modulus degrade over time if the geocell fabric is prone to UV radiation, moisture, or chemicals. Geocell hdpe is infused with UV stabilizers all through manufacturing, stopping photo-oxidation (breakdown from sunlight) that weakens tensile strength. It is additionally hydrophobic (water-resistant) and chemically inert, so moisture and soil contaminants won’t erode its modulus or structural integrity. This sturdiness ensures geocell hdpe retains its key homes for decades, turning in long-term overall performance in out of doors and harsh environments.

Manufacturing Precision

Geocell hdpe is produced thru extrusion, a procedure that ensures uniform thickness and molecular alignment. Consistent thickness skill tensile electricity and modulus are evenly disbursed throughout the geocell panels, warding off susceptible factors that lead to failure. The extrusion method additionally permits producers to tailor modulus to precise applications—for example, stiffer geocells for high-load infrastructure tasks or greater bendy choices for residential slopes. This customization makes geocell hdpe versatile throughout a vary of geocell solutions.

How Tensile Strength and Modulus Impact Geocell Slope Protection

Geocell slope safety depends on tensile electricity and modulus to function three integral functions, all of which immediately have an effect on long-term stability:

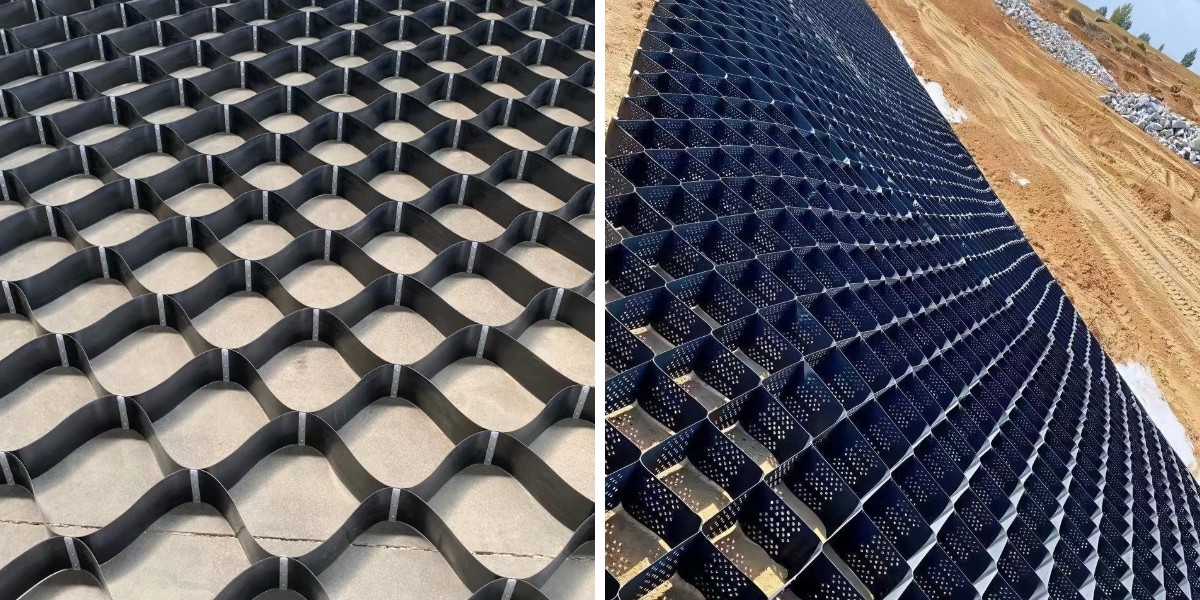

Confinement of Fill Material

Geocells entice soil, aggregate, or vegetation in their cells, stopping erosion and stabilizing the slope. Tensile power ensures the telephone partitions don’t tear when the fill fabric is compacted or shifts. Modulus ensures the cells don’t stretch or crumple below the weight of the fill, retaining the shape that locks the cloth in place. Without ample tensile strength, the cells may additionally rupture, permitting soil to escape. Without the proper modulus, the cells can also sag, lowering confinement and growing erosion risk.

Resistance to Slope Movement

Slopes naturally journey minor motion due to soil settlement, freeze-thaw cycles, or water pressure. Geocell slope safety with excessive tensile electricity resists the pulling forces from this movement, anchoring the slope and stopping landslides. A balanced modulus permits the geocell to flex barely with the motion besides breaking, whilst nevertheless imparting sufficient stiffness to restriction immoderate displacement. For steep slopes or unstable soil, geocell hdpe’s optimized houses are crucial to counteract these forces over time.

Durability Through Project Lifespan

Long-term slope safety requires substances that continue their residences for 10+ years. Geocell hdpe’s tensile power and modulus face up to degradation from UV light, moisture, and wear, making sure the geocell continues to function as designed. For example, in coastal slope protection, the place saltwater and extreme daylight are steady threats, geocell hdpe keeps its tensile power and modulus, outperforming substances like polypropylene (PP) that degrade faster. This durability reduces protection charges and avoids the want for untimely replacement.

Selecting the Right Geocell Solutions: Matching Properties to Project Needs

To make sure long-term performance, pick out geocell options with tensile power and modulus tailor-made to your project’s particular challenges:

Evaluate Slope Characteristics

Steeper slopes or slopes with loose, unstable soil require geocell options with greater tensile power to face up to gravitational pull and soil movement. A greater modulus is additionally crucial here, as the geocell wishes to hold structure beneath expanded load. For mild slopes or secure soil, a balanced tensile power and reasonable modulus may also be sufficient, providing fee financial savings besides compromising performance.

Consider Environmental Conditions

Projects in sunny, uncovered areas want geocell hdpe with strong UV stabilizers to defend tensile power and modulus from degradation. Coastal or moist environments require waterproof substances like HDPE, which won’t lose electricity when uncovered to moisture. Industrial websites or slopes close to chemical sources gain from geocell hdpe’s chemical inertness, making sure tensile energy and modulus stay unaffected with the aid of contaminants.

Align with Project Lifespan

Short-term initiatives (e.g., transient development website online slopes) may additionally use geocells with decrease tensile power and modulus, as they don’t require many years of performance. Long-term initiatives (e.g., motorway embankments, everlasting landscaping) demand geocell hdpe with excessive tensile electricity and a long lasting modulus, as the geocell need to keep its homes for the project’s complete lifespan. Investing in these homes upfront avoids pricey repairs or replacements later.

Installation Best Practices to Preserve Tensile Strength and Modulus

Even the satisfactory geocell options will underperform if set up incorrectly. Follow these practices to defend tensile energy and modulus:

Prepare the Slope Surface

Clear the slope of rocks, debris, and sharp objects that ought to puncture the geocell or create stress points. A smooth, compacted floor ensures the geocell distributes load evenly, stopping localized stretching that weakens tensile strength. For uneven slopes, use a geotextile underlay to add a shielding layer and enhance contact between the geocell and soil.

Avoid Overstretching During Installation

When unrolling and anchoring geocell hdpe, keep away from pulling it too tight. Overstretching lines the material, lowering its tensile energy and altering its modulus. Leave a small quantity of slack to accommodate thermal enlargement and contraction, which prevents the geocell from tearing in excessive temperatures. Use acceptable anchoring strategies (e.g., stakes, trenches) to tightly closed the geocell except making use of immoderate tension.

Properly Fill the Geocells

Fill the geocells with the endorsed cloth (soil, aggregate, or vegetation) in layers, compacting every layer gently. Overfilling or the use of overly heavy fabric can exceed the geocell’s tensile strength, inflicting seams to tear. Underfilling reduces confinement, placing pointless stress on the mobilephone partitions and compromising modulus. Follow producer hints for fill depth and compaction to preserve the geocell’s structural integrity.

Conclusion: Tensile Strength and Modulus Are Non-Negotiable for Long-Term Success

Tensile power and modulus are the spine of dependable geocell solutions, identifying how nicely geocell slope safety performs over time. Geocell hdpe stands out as the perfect material, imparting a balanced aggregate of tensile power to withstand tearing and modulus to keep shape—all whilst withstanding environmental degradation.

By appreciation these residences and matching them to your project’s slope characteristics, environmental conditions, and lifespan, you can pick a geocell that gives you long-term stability. Proper set up similarly preserves these key properties, making sure your geocell options defend slopes, stop erosion, and keep away from untimely failure. When it comes to geocell performance, tensile electricity and modulus aren’t simply technical specifications—they’re the warranty of a assignment that stands the take a look at of time.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province