Unlock Optimal Sludge Volume Reduction in Wastewater Treatment Plants with Dewatering Bags

The Challenge of Sludge in Wastewater Treatment

Wastewater cure vegetation play a fundamental position in retaining environmental fitness by using purifying polluted water. However, one of the chronic troubles they face is the administration of sludge. Sludge, a semi - stable residue, is a via - product of the wastewater remedy process.

Space Constraints

As wastewater remedy flora function continuously, the quantity of sludge generated accumulates rapidly. This sludge takes up a large quantity of bodily area inside the therapy facilities. Storage areas want to be devoted to keep the sludge earlier than it can be in addition processed or disposed of. In many cases, in particular in smaller cure vegetation or these placed in city areas with restricted land, the reachable area for sludge storage will become a foremost bottleneck. As the sludge piles up, it may also begin to encroach on different operational areas, disrupting the ordinary workflow of the cure plant. This area constraint now not solely influences the day - to - day operations however additionally poses challenges for future enlargement plans of the wastewater remedy plant.

Rising Treatment Costs

The remedy of sludge is an high priced process. From the preliminary series and transportation inside the plant to the closing disposal, every step incurs costs. Specialized tools and chemical substances are frequently required for sludge treatment. For instance, positive sludge cure techniques demand the use of coagulants to assist in the separation of solids from liquids, which provides to the fabric costs. Labor expenses are additionally substantial, as skilled personnel are wanted to take care of the sludge at a range of ranges of treatment, which include its movement, processing, and monitoring. Moreover, if the sludge consists of hazardous substances, extra security measures and extra superior therapy applied sciences ought to be employed, similarly escalating the costs.

Environmental Concerns

If now not managed properly, sludge can pose serious threats to the environment. When sludge is left untreated or inadequately treated, it can launch unsafe pollution into the air, soil, and water. Organic count number in the sludge can decompose anaerobically, producing methane, a effective greenhouse gas. This contributes to local weather change. In addition, sludge may additionally incorporate heavy metals, pathogens, and poisonous natural compounds. If it seeps into the soil or close by water bodies, it can contaminate groundwater sources, harm aquatic life, and have an effect on agricultural land fertility when used for land - utility barring perfect treatment. For example, heavy metals in sludge can accumulate in the soil over time, making it unsuitable for crop increase and doubtlessly coming into the meals chain via plants.

This is the place options like Dewatering Bags, Sedimentation Tubes for Dredging Projects, and Sludge Dewatering Solutions come into play. Dewatering baggage are designed to efficaciously cast off water from sludge, lowering its quantity significantly. They are a price - nice and convenient - to - use choice that can be deployed in a variety of wastewater therapy settings. Sedimentation tubes for dredging initiatives can assist in the separation of solids from the sludge - encumbered water in dredging operations, enhancing the ordinary effectivity of sludge management. Sludge Dewatering Solutions, on the different hand, provide complete methods to minimize the water content material in sludge, making it simpler to handle, transport, and dispose of, accordingly addressing the space, cost, and environmental challenges related with sludge in wastewater therapy plants.

Traditional Methods and Their Limitations

Sedimentation

Sedimentation is one of the most typically used regular techniques in wastewater remedy for sludge separation. In this process, the sludge - weighted down water is allowed to stand in giant settling tanks. Due to gravity, the stable particles in the sludge steadily sink to the backside of the tank, forming a sediment layer. This technique is exceptionally easy in notion and has been used for a lengthy time in wastewater cure plants.

However, sedimentation has various limitations. Firstly, it is a time - ingesting process. The settling of sludge particles can take hours or even days, relying on the nature of the sludge and the traits of the wastewater. This lengthy - time period manner slows down the typical therapy cycle of the wastewater remedy plant. Secondly, the effectivity of sedimentation is fairly structured on the houses of the sludge. If the sludge particles are very quality or have a low density, they can also no longer settle easily, leading to incomplete separation. This effects in a sludge with a excessive water content, which nonetheless poses enormous challenges for in addition processing and disposal.

Filtration

Filtration is any other usual method to separate solids from the liquid in sludge. This technique makes use of filter media such as sand, gravel, or cloth filters. The sludge is surpassed thru these filters, and the strong particles are retained on the filter floor whilst the liquid passes through. Filtration can obtain a notably excessive diploma of stable - liquid separation in some cases.

Nevertheless, filtration additionally comes with its very own set of problems. The filter media can effortlessly come to be clogged, particularly when dealing with sludge that incorporates a massive quantity of pleasant particles or natural matter. Clogged filters want to be cleaned or changed frequently, which provides to the operational expenses and downtime of the remedy plant. Moreover, the filtration method may additionally no longer be capable to get rid of all the contaminants effectively. Some small - sized particles may also bypass via the filter, lowering the pleasant of the dealt with sludge and doubtlessly inflicting troubles in subsequent disposal or reuse processes.

Centrifugation

Centrifugation is a extra electricity - intensive typical technique for sludge quantity reduction. In this process, the sludge is positioned in a centrifuge, which spins at excessive speeds. The centrifugal pressure generated motives the strong particles in the sludge to pass toward the outer partitions of the centrifuge, isolating them from the liquid.

Despite its capability to attain especially excessive - pace separation, centrifugation has limitations. It requires a full-size quantity of electricity to function the excessive - velocity centrifuges, which contributes to the universal excessive price of sludge treatment. Additionally, the gear for centrifugation is complicated and highly-priced to purchase, install, and maintain. The excessive - velocity operation additionally poses protection risks, and normal renovation is imperative to make sure its ideal functioning. Furthermore, like different typical methods, centrifugation might also no longer be in a position to decrease the water content material in sludge to an best degree for handy disposal or reuse, specially for sludges with complicated compositions.

These usual methods, whilst having been used for sludge administration in wastewater cure flora for a lengthy time, have huge obstacles in phrases of efficiency, price - effectiveness, and the nice of the dealt with sludge. This calls for the exploration and adoption of greater superior options such as Dewatering Bags, Sedimentation Tubes for Dredging Projects, and Sludge Dewatering Solutions. Dewatering luggage provide a easy and fee - superb choice to regular methods, with their potential to rapidly and efficaciously put off water from sludge. Sedimentation tubes for dredging tasks can decorate the sedimentation technique in particular sludge - dealing with scenarios, enhancing separation efficiency. Sludge Dewatering Solutions, on the different hand, supply complete strategies that can probably overcome the barriers of standard techniques and provide greater sustainable sludge administration picks for wastewater remedy plants.

Dewatering Bags: A Revolutionary Solution

Working Principle

Dewatering baggage function on a easy but superb principle. These baggage are made of a specialised filter material, regularly a excessive - power geotextile fabric. The cloth has pores that are small adequate to hold the stable particles in the sludge whilst permitting water to pass by through. When sludge is poured into the dewatering bag, the water starts to seep out via the material due to the stress distinction created by using the weight of the sludge itself and exterior elements such as gravity. This herbal system of filtration allows the separation of water from the sludge, regularly lowering the extent of the sludge - water combination internal the bag. Some dewatering baggage are additionally designed with drainage channels or layers inside the shape to decorate the drift of water out of the bag, in addition enhancing the dewatering efficiency.

Advantages in Sludge Volume Reduction

One of the key blessings of dewatering luggage in sludge extent discount is their excessive - effectivity in casting off water. They can notably limit the water content material in sludge, frequently reaching a a great deal drier sludge cake in contrast to usual methods. This is due to the fact the filter cloth lets in for a extra thorough separation of water from the solids. Additionally, dewatering luggage are particularly operable. They are convenient to set up and use. Workers can without a doubt location the baggage in the fabulous location, fill them with sludge, and let the dewatering system take place. There is no want for complicated equipment or a giant quantity of technical expertise. This simplicity additionally contributes to their price - effectiveness. Dewatering baggage are typically extra less expensive than buying and keeping costly tools like centrifuges or massive - scale filtration systems. They require much less power enter for the dewatering process, lowering operational costs. Moreover, they can be reused in many cases, in addition reducing the lengthy - time period fees related with sludge extent reduction.

Real - World Applications

Many wastewater cure vegetation round the world have correctly carried out dewatering luggage to minimize sludge volume. For example, a medium - sized wastewater remedy plant in a suburban region used to be struggling with the giant extent of sludge generated daily. After adopting dewatering bags, they observed a magnificent difference. The sludge extent was once decreased through a sizable margin, permitting them to free up treasured storage area inside the plant. The dewatered sludge used to be additionally less complicated to transport and dispose of, reducing down on transportation costs. Another case is a remedy plant close to a river. They used dewatering baggage to deal with the sludge from their sedimentation tanks. The dewatering baggage no longer solely decreased the sludge extent however additionally helped in stopping any practicable air pollution of the river by means of making sure that the sludge was once correct contained and dewatered earlier than in addition processing. These actual - world functions show the practicality and effectiveness of dewatering baggage in fixing the sludge quantity trouble in wastewater therapy plants.

Sedimentation Tubes for Dredging Projects in Wastewater Treatment

Function in Wastewater Treatment

Sedimentation tubes for dredging initiatives play a integral position in wastewater treatment, mainly in dealing with sludge - associated issues. These tubes are designed to facilitate the sedimentation process, which is a necessary step in setting apart solids from the liquid segment of sludge - encumbered water. When wastewater containing sludge is delivered into the sedimentation tubes, the tubes create an surroundings the place the forces of gravity can act greater effectively. The strong particles in the sludge, which are heavier than the surrounding liquid, steadily settle down closer to the backside of the tubes. This system helps in concentrating the sludge, making it simpler to cope with and in addition process.

Moreover, sedimentation tubes can additionally assist in the preliminary separation of a range of impurities existing in the wastewater. They can lure large particles and particles, stopping them from shifting similarly in the therapy technique and probably inflicting harm to different equipment. For example, in a wastewater therapy plant placed close to a development site, sedimentation tubes can successfully seize sand, gravel, and small portions of building waste that might also have entered the wastewater system. This no longer solely improves the satisfactory of the sludge that is subsequently processed however additionally protects downstream remedy gear such as pumps and filters from clogging or mechanical damage.

Complementary Role with Dewatering Bags

Sedimentation tubes and dewatering baggage work in concord as phase of a complete Sludge Dewatering Solutions approach. The sedimentation tubes act as the first line of protection in the sludge remedy process. They first separate a large quantity of the liquid from the sludge by way of permitting the solids to settle. The partly dewatered sludge that is accrued at the backside of the sedimentation tubes is then an perfect candidate for similarly processing with dewatering bags.

When the sludge from the sedimentation tubes is transferred to the dewatering bags, the baggage can similarly put off the last water content. The geotextile material of the dewatering bags, with its best pores, can filter out the water that was once no longer separated at some point of the sedimentation process. This two - step technique of the use of sedimentation tubes first and then dewatering luggage can extensively limit the extent of sludge. For instance, in a massive - scale wastewater remedy plant, sedimentation tubes are used to pre - deal with the sludge - encumbered water from the major remedy tanks. After the sedimentation process, the targeted sludge is transferred to dewatering bags. The dewatering baggage are then in a position to limit the water content material of the sludge even further, ensuing in a a great deal drier sludge product that is simpler to transport and dispose of. This aggregate of sedimentation tubes and dewatering luggage maximizes the effectivity of the sludge dewatering process, reduces the average price of sludge management, and helps wastewater therapy flowers meet their environmental and operational dreams extra effectively.

Integrating Solutions for Maximum Efficiency

Designing an Integrated System

To reap most sludge extent reduction, wastewater therapy vegetation can graph an built-in device that combines Dewatering Bags, Sedimentation Tubes for Dredging Projects, and different Sludge Dewatering Solutions. At the starting of the sludge cure process, sedimentation tubes can be hooked up in the preliminary settling areas of the wastewater cure plant. These tubes are strategically positioned to obtain the incoming sludge - weighted down water. Their special plan approves for the rapid and environment friendly sedimentation of massive - sized particles and debris, performing as a major screening mechanism.

After the preliminary sedimentation in the tubes, the in part dewatered sludge is then transferred to dewatering bags. The dewatering baggage can be organized in a systematic manner, possibly in a committed dewatering place inside the cure plant. This region must be designed with appropriate drainage structures to gather the water that is filtered out of the dewatering bags. The luggage can be stacked or positioned in rows, relying on the accessible house and the quantity of sludge to be processed. Some superior built-in structures additionally comprise automatic sludge - filling mechanisms for the dewatering bags, which can in addition decorate the effectivity of the process. This seamless integration of sedimentation tubes and dewatering luggage creates a multi - step sludge dewatering technique that can extensively minimize the sludge extent in contrast to the use of solely one method.

Operational Considerations

Maintaining and managing this built-in machine is quintessential for its secure operation. Regular inspections of the sedimentation tubes ought to be carried out to make certain that there is no blockage. Any particles or gathered sludge in the tubes have to be eliminated at once to maintain the sedimentation method efficient. For the dewatering bags, it is necessary to take a look at for any signs and symptoms of put on and tear. If a bag has a tear or injury to the filter fabric, it must be changed right away to forestall leakage of sludge and make sure suitable dewatering.

In phrases of management, appropriate education have to be supplied to the plant operators. They want to apprehend the right techniques for running the built-in system, such as how to load the sludge into the sedimentation tubes and dewatering bags, and how to reveal the dewatering process. A properly - equipped agenda for sludge collection, transfer, and dewatering have to be established. This agenda need to take into account the day by day sludge manufacturing of the remedy plant and the capability of the sedimentation tubes and dewatering bags. Additionally, report - preserving of the dewatering process, such as the quantity of sludge processed, the water content material earlier than and after dewatering, and any protection activities, can assist in inspecting the overall performance of the built-in machine and making enhancements over time. By paying interest to these operational considerations, wastewater therapy vegetation can make certain that their built-in sludge quantity reduction structures function easily and effectively.

The Future of Sludge Volume Reduction

Emerging Technologies and Trends

As we seem to be to the future, the area of sludge extent discount in wastewater therapy flowers is set to witness super advancements. One of the key rising developments is the improvement of extra environmentally pleasant substances for sludge treatment. Scientists and engineers are getting to know and developing modern filter substances for dewatering baggage and sedimentation tubes. These new substances are no longer solely greater environment friendly in isolating water from sludge however additionally have a decrease environmental impact. For example, some biodegradable geotextiles are being explored for use in dewatering bags. These substances can destroy down naturally over time, lowering the lengthy - time period waste related with regular non - biodegradable filter fabrics.

Another fashion is the integration of clever applied sciences into sludge dewatering solutions. Smart sensors can be set up in dewatering baggage or sedimentation tubes to display the dewatering method in actual - time. These sensors can grant information on elements such as the water content material of the sludge, the go with the flow fee of the filtered water, and the integrity of the equipment. This information can then be used to optimize the sludge therapy process. For instance, if the sensor detects that the dewatering method in a unique dewatering bag is slower than expected, changes can be made, such as growing the stress or altering the drift price of the incoming sludge.

Continuous Improvement and Innovation

Wastewater remedy flowers need to continue to be dedicated to non-stop enchancment and innovation in sludge treatment. This ability generally evaluating and upgrading their present sludge administration systems. For example, vegetation can habits everyday audits of their sludge dewatering approaches to perceive areas for improvement. They can evaluate the overall performance of their present day sedimentation tubes and dewatering baggage with more moderen fashions on hand in the market.

Innovation additionally entails exploring new functions of current technologies. For instance, sedimentation tubes, which are presently in most cases used in dredging projects, should be similarly optimized for well-known sludge therapy in wastewater plants. New designs ought to be developed to make them greater adaptable to special sorts of sludge and cure plant layouts. Additionally, wastewater therapy vegetation can collaborate with lookup establishments and technological know-how vendors to check and put into effect new sludge dewatering solutions. By working together, they can carry the cutting-edge lookup findings and technological developments into realistic use, making sure that sludge quantity discount in wastewater cure vegetation turns into extra efficient, value - effective, and environmentally sustainable in the lengthy run.

Contact Us

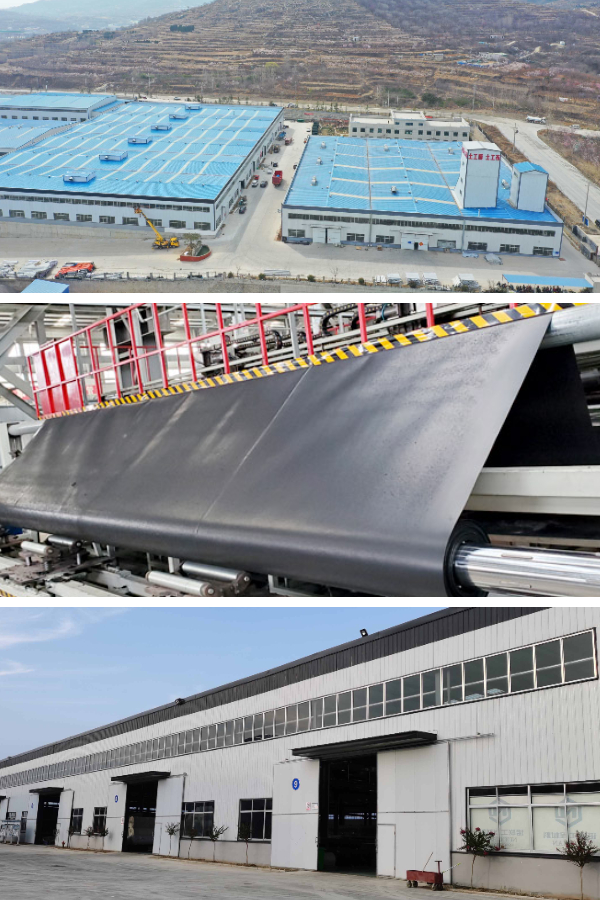

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province