Tensile Strength and Elongation: Ensuring Durability in HDPE Liners

In containment applications—from landfills and wastewater ponds to mining tailings and agricultural reservoirs—hdpe liner (high-density polyethylene liner) is a cornerstone material. Renowned for its impermeability and chemical resistance, it acts as a imperative barrier towards leaks and environmental contamination. But two often-overlooked houses decide its long-term success: tensile power and elongation. These mechanical traits without delay have an impact on how properly an hdpe geomembrane can face up to stress, adapt to web page conditions, and keep away from failure. This information breaks down what tensile power and elongation imply for hdpe liner performance, why they’re vital for durability, and how to consider these houses when choosing an impermeable geomembrane liner for your project.

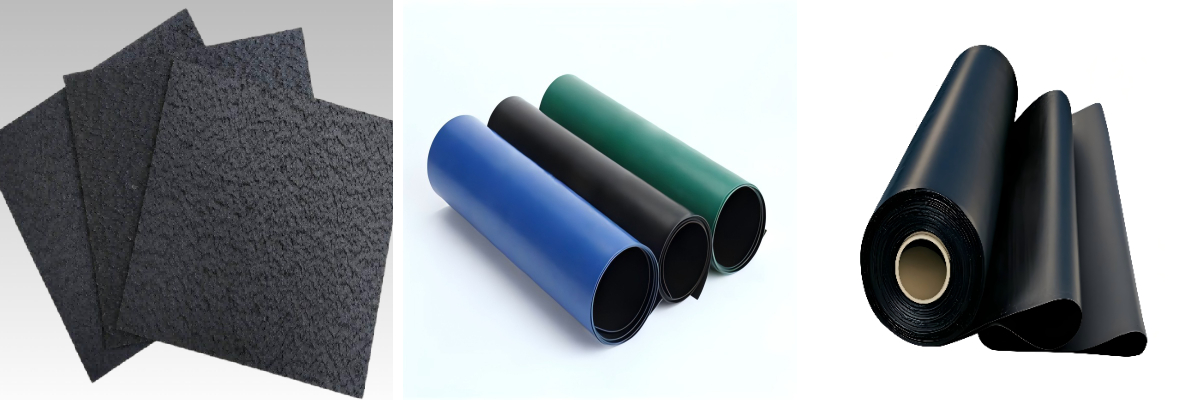

Understanding HDPE Liners: Beyond Impermeability

Hdpe liner, additionally referred to as hdpe geomembrane, is a artificial sheet crafted from high-density polyethylene—a thermoplastic polymer valued for its dense molecular structure. This shape makes it an remarkable impermeable geomembrane liner, blocking off the passage of liquids, gases, and contaminants. Yet, impermeability on my own isn’t ample for long-term durability. Liners face consistent stressors: soil movement, temperature swings, set up tension, and the weight of overlying material. Tensile energy and elongation are the houses that allow hdpe liner to withstand these stresses besides tearing or failing.

Whether lining a municipal landfill or an industrial chemical tank, a liner with bad tensile power or elongation will crack, puncture, or stretch past repair—compromising the whole containment system. That’s why grasp these homes is simply as necessary as verifying impermeability.

Tensile Strength: The Liner’s Resistance to Pulling Forces

Tensile energy is the most pulling pressure an hdpe geomembrane can undergo earlier than breaking. Think of it as the liner’s “strength limit”—exceed this force, and the cloth tears. For hdpe liner, tensile energy is measured by using pressure per unit width and varies based totally on thickness, manufacturing processes, and additive packages.

Why Tensile Strength Is Non-Negotiable

During installation, hdpe liner is stretched over uneven terrain, anchored at edges, and frequently pulled tight to dispose of wrinkles. Insufficient tensile electricity leads to tearing throughout this process. Post-installation, soil contract or growth (from wetting and drying) exerts pulling forces. A high-tensile-strength impermeable geomembrane liner resists these forces, retaining integrity even as the floor shifts.

In heavy-duty purposes like mining tailings ponds, tens of millions of lots of sediment press down on the liner, growing lateral tensile stress. Without enough tensile strength, the liner stretches and ruptures, inflicting catastrophic leaks of poisonous waste. For chemical containment, tensile power additionally helps the liner withstand saved liquid pressure, specifically in tall tanks or deep pits.

Elongation: The Liner’s Flexibility to Stretch Without Breaking

Elongation (often “elongation at break”) is the share an hdpe liner can stretch earlier than tearing. This property is integral for hdpe geomembrane due to the fact it lets the liner adapt to minor moves and stresses—unlike inflexible substances that crack when stretched.

Why Elongation Matters for Longevity

Temperature fluctuations are a frequent stressor. HDPE expands in warmth and contracts in cold; barring adequate elongation, repeated cycles crack the liner at seams or anchor points. Elongation additionally aids installation: if the liner is barely misaligned, its stretchability permits changes besides tearing.

In landfills, waste decomposition generates gasoline that creates small bulges. A liner with accurate elongation stretches to accommodate these bulges rather of puncturing. For riverbank or coastal containment, wave motion or water stress pulls on the liner—elongation ensures it flexes as a substitute than breaking.

The Synergy of Tensile Strength and Elongation

Tensile electricity and elongation work collectively for hdpe liner durability. A liner with excessive tensile power however low elongation is brittle—it resists sturdy pulls however cracks when stretched. One with high elongation however low tensile energy is weak—it stretches effortlessly however tears beneath reasonable force.

The best impermeable geomembrane liner balances both. Most hdpe geomembrane is engineered for reasonable to excessive tensile electricity and enough elongation to take care of usual web site stresses. For example, a landfill liner desires tensile electricity to withstand soil motion and elongation to accommodate temperature adjustments and gasoline bulges.

Factors Influencing Tensile Strength and Elongation

Several elements have an effect on these homes in hdpe liner:

1. Thickness

Thicker hdpe geomembrane normally has greater tensile strength, as extra fabric resists pulling forces. Thickness has much less affect on elongation—thin liners can nonetheless have properly elongation with suited additives.

2. Manufacturing Process

HDPE liners are made by using extrusion, the place molten HDPE is pressed thru a die. Extrusion velocity and temperature have an effect on polymer molecular alignment. Liners with uniform alignment have higher tensile energy and elongation.

3. Additives

Manufacturers add UV stabilizers, antioxidants, and plasticizers to hdpe liner. UV stabilizers defend tensile power from solar damage, whilst plasticizers raise elongation by using growing flexibility.

How to Evaluate These Properties When Choosing a Liner

When deciding on an hdpe liner, don’t depend totally on producer claims—seek third-party check reviews verifying tensile power and elongation, the usage of standardized assessments for regular measurement.

Match liner homes to venture stressors:

High-stress websites (landfills, mining): Choose hdpe geomembrane with excessive tensile energy and average elongation.Moderate-stress websites (agricultural ponds, residential water features): Opt for a balanced liner with reasonable tensile electricity and elongation.Extreme-temperature web sites (deserts, bloodless climates): Prioritize elongation and make sure UV stabilizers defend tensile strength.

Conclusion: Durability Begins With Balance

Tensile electricity and elongation are unsung heroes of hdpe liner durability. While impermeability is key for an impermeable geomembrane liner, these mechanical houses let the liner face up to real-world stresses of installation, web page conditions, and time. A well-balanced hdpe geomembrane protects in opposition to leaks, cuts protection costs, and lasts decades.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province