Improving Concrete Durability and Finish with Proper Curing Techniques

Pouring exquisite concrete is a science, however its long-term overall performance is an artwork mastered via one integral step: appropriate curing. Many contractors and DIY lovers center of attention on the combine plan and placement, solely to see their efforts undermined by means of insufficient aftercare. The fact is, the work you do after the pour is what unlocks the concrete's authentic potential. This article delves into the necessary practices of concrete curing, explaining how they are the final keys to accomplishing superb durability and a flawless surface finish.

Why Curing is Non-Negotiable for High-Performance Concrete

Curing is the system of retaining enough moisture and temperature in concrete for a enough duration after placement. This lets in the chemical response of hydration to continue. When water is conveniently available, cement particles utterly react, producing extra of the strong, binding crystals that supply concrete its strength. Neglecting this method leads to a weak, porous, and brittle matrix. Proper curing without delay enhances the concrete's long-term durability, making it resistant to freezing and thawing cycles, chemical attacks, and abrasion. Furthermore, it is the single most necessary component in stopping plastic shrinkage cracks and attaining a hard, dense, and aesthetically desirable surface finish.

The Science of Hydration: The Foundation of Durability

To recognize curing, you need to recognize hydration. When cement mixes with water, a complicated response begins, forming calcium silicate hydrate (C-S-H) gel. This gel is the glue that binds the aggregates together, growing the strong mass we be aware of as concrete. However, this response requires a non-stop provide of water. If the concrete dries out too quickly, the hydration manner stops prematurely.

An under-hydrated concrete slab will in no way improve its meant energy or density. It stays riddled with capillary pores, permitting water and hazardous chemical compounds to penetrate easily. This compromises the structural integrity and extensively reduces the durability of the installation. For the surface finish, this capability a susceptible pinnacle layer that is susceptible to dusting, scaling, and craze cracking, fully destroying its visible enchantment and purposeful performance.

Essential Curing Methods for Superior Results

There are numerous positive curing techniques, every applicable to exceptional challenge conditions. The purpose of all strategies is to forestall moisture loss for a minimal of seven days, or longer in bloodless weather.

Water Curing: The Gold Standard

Water curing is one of the most tremendous techniques due to the fact it at once elements water to the surface.

Ponding: Typically used for flat surfaces like slabs, this includes developing small earth or sand dams to maintain a layer of water over the complete slab.

Sprinkling & Fogging: Using a first-rate mist or sprinkler machine continues the floor constantly moist besides inflicting erosion or temperature shock. This is high-quality for reaching a uniform surface finish free from crack lines.

Saturated Coverings: Burlap or cotton mats can be soaked and positioned on the concrete surface, requiring ordinary re-wetting to maintain them saturated.

While incredibly effective, water curing can be labor-intensive and wasteful, making it much less sensible for some large-scale or vertical applications.

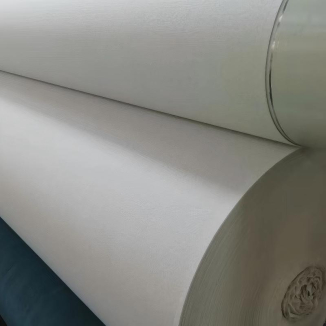

Moisture-Retaining Covers: A Practical and Efficient Solution

This class consists of plastic sheets, water-proof paper, and particularly formulated curing compounds. They work by means of forming a bodily barrier that traps moisture inside the concrete.

Plastic Sheeting: Polyethylene movie is a common, less expensive choice for flatwork. It should be laid straight away after the remaining surface finish is completed and sealed at the edges to stop moisture escape. A key disadvantage is that it can motive discoloration if no longer utilized uniformly and can also stick to the surface finish, probably marring it.

The Modern Solution: Cement Blanket: For tasks requiring greater than simply moisture retention, a specialised cement blanket affords a highest quality solution. Unlike easy plastic, a outstanding cement blanket is designed to now not solely entice moisture efficiently however additionally to grant thermal insulation. This is critical for retaining an perfect temperature for hydration, defending the sparkling concrete from the negative outcomes of early-age freezing or overheating. By making sure a stable, moist environment, a cement blanket at once promotes the improvement of a high-strength matrix that underpins long-term durability and a consistent, amazing surface finish.

The Direct Link Between Curing, Durability, and Finish

Let's wreck down the tangible advantages you acquire from a disciplined curing regimen.

How Curing Builds Unmatched Durability

A thoroughly hydrated cement paste has a dense, impermeable microstructure. This density is the principal protection mechanism in opposition to nearly all frequent reasons of concrete failure.

Freeze-Thaw Resistance: When water internal the pores freezes, it expands. In porous concrete, this creates monstrous inside pressure, main to scaling and spalling. A well-cured, dense concrete has fewer water-filled pores, dramatically growing its durability in bloodless climates.

Abrasion and Wear Resistance: High-traffic surfaces like industrial flooring or driveways want to stand up to steady friction. The hard, dense surface produced with the aid of appropriate curing is some distance extra resistant to abrasion, making sure a longer carrier life.

Chemical Attack Prevention: Dense concrete slows the ingress of de-icing salts, sulfates, and different chemical compounds that can degrade the binder. This superior durability is fundamental for infrastructure and business applications.

Achieving the Perfect Surface Finish Through Controlled Curing

The pinnacle layer of a concrete slab is the most vulnerable. It is uncovered to evaporation first and is regularly labored appreciably throughout finishing. If this floor dries quicker than the underlying concrete, differential shrinkage occurs, main to plastic shrinkage cracks.

Preventing Crazing and Cracking: By keeping a uniform moisture content material from the floor down, curing eliminates the stress that motives early-age cracking. This effects in a smooth, intact surface finish.

Eliminating Dusting: Dusting, the formation of a fine, powdery residue on the surface, is regularly a direct end result of terrible curing. A susceptible surface layer fails to bind the particles together. Proper curing ensures a strong, cohesive pinnacle layer that is imperative to the slab beneath, retaining the surface finish.

Consistent Color and Texture: Uneven drying or the use of non-uniform covers (like wrinkled plastic) can lead to discoloration and a blotchy appearance. A regular curing method, such as the usage of a cement blanket, ensures an even moisture distribution, which is vital for a uniform colour and texture in the closing surface finish.

Best Practices for an Effective Curing Strategy

To maximize the benefits, comply with these guidelines:

1. Start Immediately: Begin curing as quickly as the concrete has hardened sufficiently to withstand floor damage, straight away after the last ending operations. On sunny or windy days, this may additionally suggest beginning inside minutes of putting the concrete to forestall plastic shrinkage cracks from forming.

2. Maintain Duration: For traditional concrete mixes, keep curing for a minimal of 7 days at 70°F (21°C) or longer in chillier temperatures. For concrete with supplementary cementitious materials, a longer curing duration of 10-14 days is notably really useful for creating durability.

3. Control Temperature: The best temperature vary for curing is between 50°F and 70°F (10°C and 21°C). In warm weather, use techniques that preserve moisture and grant cooling. In bloodless weather, focal point on techniques that furnish each moisture retention and insulation—this is the place the thermal houses of a cement blanket emerge as beneficial for defending your funding and making sure suited power gain.

Conclusion: An Investment in Long-Term Performance

Curing is now not an non-obligatory step; it is the final, vital segment of producing top notch concrete. By dedicating time and assets to perfect curing techniques, you are making a direct funding in the longevity, resilience, and splendor of your concrete structure. Whether you pick out typical ponding or current options like a cement blanket, the precept stays the same: manage moisture and temperature to unencumber the full manageable of the material. The reward is a shape with most desirable durability that will stand the take a look at of time, topped with a pristine surface finish that displays the first-rate of the workmanship from begin to finish. Don't let your tough work go to waste—plan your curing method with the identical care as your combine design.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province