Step-by-Step HDPE Geomembrane Installation Guide: Tips for Seamless, Leak-Proof Results

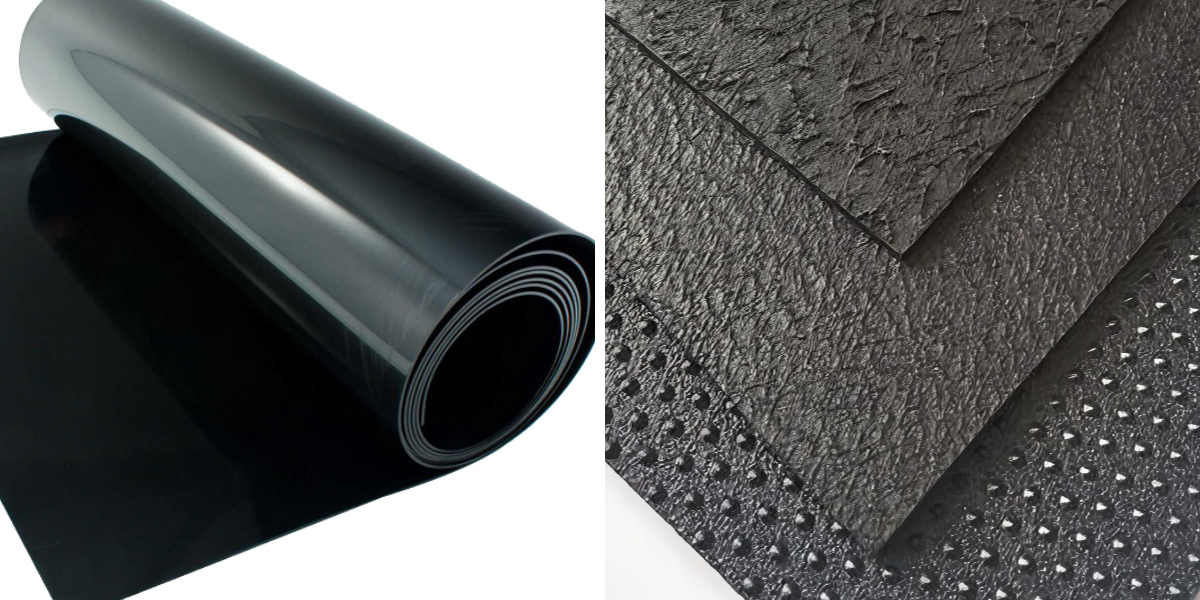

HDPE geomembrane is a versatile, long lasting fabric broadly used in waterproofing and anti-seepage tasks such as landfills, reservoirs, ponds, and building sites. Its effectiveness, however, hinges absolutely on ideal geomembrane installation. A mistaken set up can lead to leaks, structural damage, and steeply-priced repairs. In this complete guide, we’ll stroll you via the step-by-step manner of HDPE geomembrane installation, focusing on essential hints to make certain seamless, leak-proof results. Whether you’re a expert contractor or a DIY enthusiast, this information will assist you grasp the necessities of putting in HDPE liner and geomembrane systems.

1. Pre-Installation Preparation: Lay the Foundation for Successful HDPE Geomembrane Installation

The key to a easy and leak-free geomembrane set up lies in thorough pre-installation preparation. Rushing this section regularly outcomes in avoidable troubles later, such as membrane punctures or uneven surfaces that compromise seam integrity. Below are the core steps to put together your website online and substances earlier than putting in HDPE liner.

1.1 Site Assessment and Preparation

Start by way of conducting a specified website online evaluation to perceive workable risks and decide the most suitable set up strategy. First, clear the website online of all debris, rocks, roots, and sharp objects—even small protrusions can puncture the HDPE geomembrane, main to leaks. Use a rake or bulldozer to degree the surface, making sure there are no slopes steeper than the manufacturer’s hints (typically 3:1 for secure soil). For uneven terrain, fill low-lying areas with compacted soil or sand to create a smooth, company base.

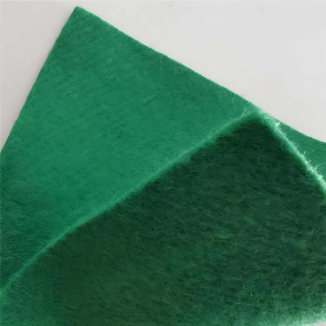

Next, verify the soil conditions. If the website has gentle or unstable soil, strengthen it with a geotextile layer earlier than putting in HDPE liner. Geotextiles add stability, forestall soil movement, and furnish an more barrier in opposition to punctures. Additionally, take a look at for groundwater or floor water accumulation; if present, set up a drainage gadget to hold the website dry for the duration of and after installation—moisture can weaken the bond between the HDPE geomembrane and the base, affecting general performance.

1.2 Material Inspection and Handling

Before commencing geomembrane installation, investigate all HDPE geomembrane rolls and add-ons (such as seam tape, adhesives, and fasteners) for damage. Check for tears, holes, or defects in the membrane, and affirm that the cloth thickness and specs in shape the mission requirements. Damaged rolls must be rejected or repaired earlier than use to keep away from compromising the installation.

Proper managing of HDPE geomembrane is additionally critical. Store rolls in a clean, dry location away from direct sunlight, as UV publicity can degrade the fabric over time. When transporting rolls to the set up site, use forklifts or cranes with gentle slings to forestall punctures or tears. Avoid dragging rolls throughout tough surfaces, and cope with them with care to keep their structural integrity.

1.3 Weather and Timing Considerations

Geomembrane set up must be carried out beneath favorable climate conditions. Avoid putting in HDPE liner at some stage in heavy rain, excessive winds, or severe temperatures (below 4°C or above 32°C). Rain can saturate the website and weaken the base, whilst excessive winds make it hard to manage and impenetrable the membrane. Extreme bloodless can make the HDPE geomembrane brittle and susceptible to cracking, whilst severe warmth can motive the fabric to expand, main to wrinkles that are difficult to easy out.

Plan the set up agenda to coincide with a duration of secure weather, and reveal forecasts closely. If surprising climate arises at some stage in installation, give up work right now and impenetrable the hooked up HDPE geomembrane with weights or anchors to stop damage.

2. Core Installation Process: Step-by-Step HDPE Geomembrane Placement

Once the website online and substances are prepared, it’s time to start the core geomembrane set up process. Follow these steps to make certain suited placement, seaming, and securing of the HDPE liner.

2.1 Unrolling and Positioning the HDPE Geomembrane

Start by using unrolling the HDPE geomembrane rolls parallel to the longest dimension of the website online to reduce the range of seams—fewer seams suggest fewer attainable leak points. Unroll the first roll carefully, making sure it lies flat towards the organized base barring wrinkles or tension. Use weights (such as sandbags) to keep the membrane in region whilst unrolling subsequent rolls.

When positioning adjoining rolls, depart a 10-15 cm overlap for seaming. Ensure the overlap is constant alongside the complete size of the rolls to preserve seam integrity. Avoid stretching the HDPE geomembrane at some stage in positioning, as this can purpose stress on the cloth and seams. If wrinkles occur, gently clean them out earlier than securing the membrane.

2.2 Seaming: The Critical Step for Leak-Proof Results

Seaming is the most essential section of geomembrane installation, as poorly sealed seams are the main reason of leaks in HDPE liner systems. There are two major seaming strategies for HDPE geomembrane: thermal fusion welding and extrusion welding. Thermal fusion welding is the most frequent technique for flat seams, whilst extrusion welding is used for corners, edges, and repairs.

For thermal fusion welding: First, easy the overlap vicinity of the HDPE geomembrane to get rid of dirt, dust, or moisture—any contaminants will weaken the seam. Adjust the welding computer to the manufacturer’s advocated temperature and velocity (typically 200-250°C for HDPE). Run the welding laptop alongside the overlap, making use of regular stress to make sure a robust bond. After welding, function a visible inspection to test for regular bead formation (a continuous, uniform bead alongside each facets of the seam shows a correct weld).

For extrusion welding: Use an extrusion welder to soften and practice HDPE resin to the seam area. This approach is best for irregular surfaces or areas the place thermal fusion welding is no longer feasible. Ensure the resin wholly bonds with the HDPE geomembrane, and easy the weld with a curler to remove air pockets.

2.3 Securing the HDPE Liner

After seaming, impervious the HDPE geomembrane to the base and edges of the web site to forestall movement. Use anchor trenches, fasteners, or weights relying on the website conditions. For anchor trenches, dig a 30-50 cm deep trench alongside the perimeter of the site, fold the facet of the HDPE geomembrane into the trench, and backfill with compacted soil. This technique presents a invulnerable anchor and prevents water from seeping below the membrane.

For sloped areas, use extra fasteners (such as concrete anchors or metal pins) to impenetrable the HDPE liner at everyday intervals. Ensure fasteners are positioned in areas that won’t puncture the membrane, and use washers to distribute strain evenly. Avoid over-securing the membrane, as this can reason stress and cracking.

3. Post-Installation Quality Control: Ensure Long-Term Leak-Proof Performance

Once geomembrane set up is complete, thorough first-class manage checking out is integral to affirm that the HDPE liner is leak-free and proper installed. Skipping this section can lead to undetected problems that solely floor later, ensuing in pricey repairs and challenge delays.

3.1 Visual Inspection

Start with a complete visible inspection of the complete HDPE geomembrane installation. Check for tears, punctures, wrinkles, or free seams. Inspect the anchor trenches and fasteners to make sure they are impenetrable and appropriate installed. Look for signs and symptoms of injury from weather, wildlife, or development equipment, and restore any problems immediately.

3.2 Leak Testing

Leak trying out is the most integral phase of post-installation first-class control. The two most frequent strategies for trying out HDPE geomembrane seams are the air stress check and the vacuum field test.

Air strain test: This technique is used for thermal fusion seams. Insert a strain gauge into a small gap drilled at one quit of the seam, and seal the different end. Apply air strain (typically 200-300 kPa) and screen the gauge for 5-10 minutes. If the strain drops, it suggests a leak in the seam. Mark the leak vicinity and restore it with extrusion welding.

Vacuum field test: This technique is appropriate for each thermal fusion and extrusion seams. Apply a soapy water answer to the seam, then area a vacuum container over the place and create a vacuum. If bubbles form, it shows a leak. Repair the leak and retest till no bubbles appear.

3.3 Post-Installation Maintenance Tips

To make certain long-term overall performance of the HDPE geomembrane, put into effect a normal protection plan. Inspect the set up periodically for damage, mainly after extreme climate or close by building activity. Keep the vicinity round the HDPE liner free of particles and sharp objects. Avoid dragging heavy tools throughout the membrane, and use shielding mats if get admission to is necessary.

If repairs are needed, use well matched HDPE substances and observe the identical seaming techniques as the authentic installation. Document all inspections and repairs to preserve a file of the HDPE geomembrane’s circumstance over time.

Final Thoughts on HDPE Geomembrane Installation

Proper geomembrane set up is the cornerstone of a leak-proof, long lasting HDPE liner system. By following the step-by-step system outlined in this guide—from thorough pre-installation guidance to specific seaming and rigorous post-installation testing—you can make certain that your HDPE geomembrane set up meets the absolute best requirements of overall performance and reliability.

Remember, each and every task is unique, so continually refer to the manufacturer’s tips and seek advice from with a expert if you come upon complicated website online conditions. With the proper preparation, tools, and techniques, you can reap seamless, leak-proof effects that stand the take a look at of time.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province