PP vs. PET Geotextiles: Material Properties, Durability, and Cost Trade-offs

When determining on geotextile cloth for construction, erosion control, or environmental projects, two supplies stand out: polypropylene (PP) and polyethylene terephthalate (PET). Both are synthetic polymers largely used in geo fabric material production, on the other hand they fluctuate notably in properties, durability, and cost. Choosing the desirable one depends upon on your project’s needs—whether you prioritize affordability, UV resistance, chemical tolerance, or long-term performance. This facts compares PP and PET geotextiles, breaking down their material characteristics, sturdiness in one-of-a-kind environments, and charge trade-offs. We’ll moreover highlight how non woven geotextile variations of each and every perform, helping you make an educated desire for your subsequent project.

Core Material Properties: PP vs. PET Geotextiles

Geotextile material standard overall performance starts with its base material. PP and PET have extremely good molecular structures that structure their key properties, from tensile strength to chemical resistance.

Polypropylene (PP) Geotextiles

PP is a lightweight, thermoplastic polymer stated for its flexibility and chemical inertness. As a geo cloth material, it offers a range of defining traits:

Density: PP is a good deal much less dense than PET, making PP geotextiles lighter and easier to take care of at some factor of installation—ideal for large-scale duties the location maneuverability matters.Chemical Resistance: It resists most acids, alkalis, and herbal solvents, making it splendid for industrial functions like wastewater therapy or mining.Water Absorption: PP is hydrophobic (water-repellent), so it doesn’t take in moisture—preventing waterlogging and maintaining structural integrity in moist environments.However, PP has limitations: it has minimize melting thing than PET and is more prone to UV degradation barring stabilizers. Non woven geotextile made from PP relies upon on fiber bonding (heat or chemical) to keep strength, which can weaken if uncovered to extreme heat.

Polyethylene Terephthalate (PET) Geotextiles

PET is a rigid, high-strength polymer many instances used in textiles and packaging. As a geo fabric material, its standout homes include:

Tensile Strength: PET has larger tensile electricity than PP, that ability it can face up to large pulling forces without tearing—critical for slope stabilization or heavy-load applications.UV Resistance: PET is inherently greater UV-resistant than PP, retaining its electrical energy longer in direct sunlight hours besides relying intently on stabilizers.Thermal Stability: It has a increased melting point, making it fabulous for duties in heat climates or shut to warmness sources (e.g., industrial sites).PET’s imperative draw back is its increased density, which makes PET geotextile material heavier and barely an awful lot much less flexible than PP. It’s moreover a good deal much less resistant to sturdy alkalis in distinction to PP.

Durability: How PP and PET Perform in Real-World Environments

Durability is a make-or-break thing for geotextile cloth, as out of doorways and industrial duties expose materials to UV radiation, weathering, and mechanical stress. Here’s how PP and PET stack up:

UV and Weather Resistance

UV radiation breaks down polymer bonds over time, inflicting geo material fabric to come to be brittle. PET’s inherent UV resistance presents it an edge: barring stabilizers, PET can closing 5–10 years in direct sunlight, even as PP would possibly additionally degrade in 1–2 years. However, PP geotextiles can be extra tremendous with UV stabilizers (like HALS) to extend their lifespan to 5–8 years.

In moist or coastal environments, every elements stand up to water absorption, on the other hand PP is greater resistant to saltwater corrosion—making it greater for marine erosion control. PET, meanwhile, handles freeze-thaw cycles increased effectively, as its strain prevents cracking from growth and contraction.

Mechanical and Chemical Durability

For duties involving heavy equipment, abrasion, or sharp debris, PET’s increased tensile electrical energy makes it higher lengthy lasting than PP. A PET non woven geotextile will face up to tearing from rocks or gear greater than a PP equivalent. In chemical-heavy settings (e.g., acid mine drainage), PP’s biggest chemical resistance makes it the safer choice—PET can degrade in pretty alkaline environments.

Biological resistance is related for both: neither PP nor PET is prone to mold, mildew, or rodent damage, as they’re inert to natural activity.

Cost Trade-offs: Affordability vs. Long-Term Value

Cost is normally a principal consideration when deciding on geotextile cloth. PP and PET fluctuate in upfront and long-term costs, developing trade-offs between on the spot monetary financial savings and future expenses.

Upfront Costs

PP geotextiles are commonly 20–30% extra not pricey than PET equivalents. This is due to the truth PP resin is plenty much less highly-priced to produce, and PP non woven geotextile requires tons much less electrical energy to manufacture (due to reduce melting point). For massive initiatives with tight budgets—like quick erosion manipulate or brief constructing sites—PP affords sizeable upfront savings.

Long-Term Costs

PET’s larger sturdiness interprets to limit long-term costs. Projects requiring 5+ years of common overall performance (e.g., eternal slope stabilization, landfill liners) will attain from PET, as it desires fewer replacements than PP. Even with UV stabilizers, PP may additionally additionally require maintenance or choice every and each and every 5–8 years, while PET can closing 10–15 years barring degradation.

For example, a toll avenue embankment the use of PET geotextiles will maintain away from the charge of re-installing PP geotextiles halfway through the project’s lifespan. The preliminary pinnacle type for PET is offset with the resource of reduced labor and cloth fees over time.

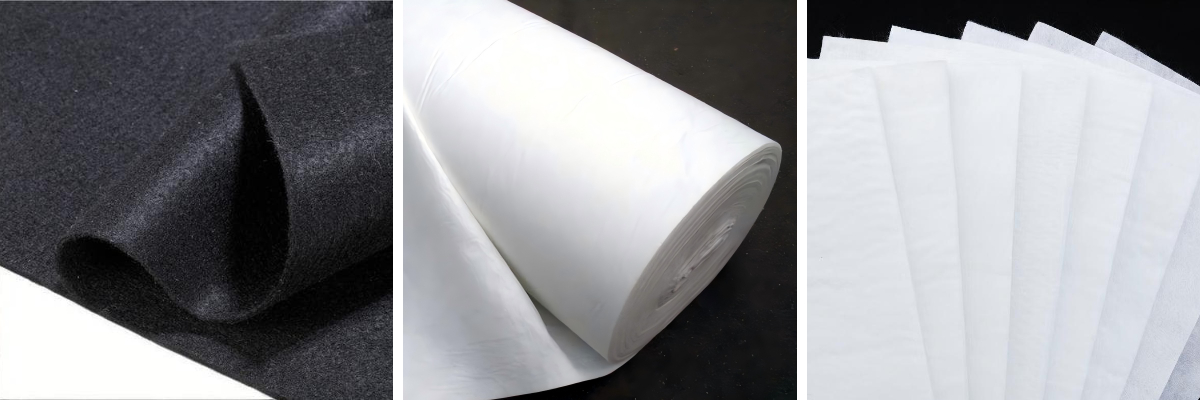

Non Woven Geotextile: PP vs. PET in Practical Applications

Non woven geotextile is the most regularly occurring variety for filtration, separation, and erosion control. Here’s how PP and PET non woven variations function in key applications:

1. Erosion Control

For non everlasting erosion control (1–3 years), PP non woven geotextiles are cost-effective. They entice soil and information seed germination at the same time as remaining lightweight. For long-term erosion control (5+ years)—like coastal dunes or mountain slopes—PET non woven geotextiles are better, as their UV resistance and tensile power make sure lasting stability.

2. Separation and Filtration

In avenue improvement (separating subgrade from gravel) or drainage constructions (filtering sediment), PP non woven geotextiles work well due to their chemical resistance and permeability. For high-load separation (e.g., railway ballast), PET non woven geotextiles control the weight better, stopping fiber breakdown below pressure.

3. Industrial Containment

For chemical ponds or mining waste containment, PP non woven geotextiles are favored for their chemical inertness. For high-temperature industrial web sites (e.g., electricity plants), PET non woven geotextiles face up to heat degradation, making them a safer choice.

How to Choose Between PP and PET Geotextiles

Use this preference framework to choose out the suited geo material cloth for your project:

Project Lifespan: Short-term (≤3 years) → PP; Long-term (≥5 years) → PET.

Environment: High UV → PET (or PP with stabilizers); Saltwater → PP; High warmness → PET; Chemical-heavy → PP.

Load and Stress: Heavy equipment, steep slopes, or immoderate tensile stress → PET; Light loads, flat terrain → PP.

Budget: Tight upfront fee vary → PP; Prioritize long-term monetary financial savings → PET.

Conclusion: Balancing Properties, Durability, and Cost

PP and PET geotextiles each supply specific advantages, and the applicable want relies upon on your project’s unique needs. PP geotextile fabric is affordable, flexible, and chemically resistant—ideal for short-term, budget-conscious projects. PET geo material material guarantees high-quality tensile strength, UV resistance, and long-term durability—perfect for permanent, high-stress applications.

When evaluating options, don’t forget about non woven geotextile variants, as their fiber form enhances filtration and separation. By weighing material properties, sturdiness requirements, and price trade-offs, you can pick out out a geotextile that meets usual overall performance needs even as staying interior budget. Whether you select PP or PET, investing in outstanding geotextile fabric ensures your project is developed to last—protecting infrastructure, the environment, and your bottom line.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province