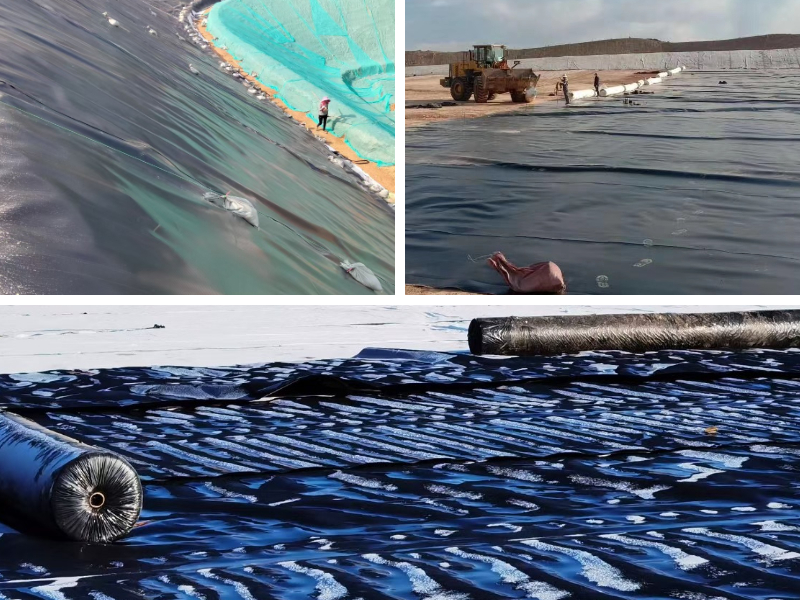

Mining Applications: HDPE Liners for Tailings Ponds and Heap Leach Pads

Mining operations rely on resilient containment structures to manipulate byproducts like tailings and manner options whilst upholding strict environmental regulations. A cornerstone of these structures is hdpe geomembrane—a high-density polyethylene liner famend for its impermeability, durability, and chemical resistance. In tailings ponds and heap leach pads, the place the danger of illness from heavy metals, chemicals, or acidic fluids runs high, impenetrable geomembrane options are non-negotiable. This information explores how hdpe geomembrane serves as the spine of mining containment, detailing its functions in tailings ponds and heap leach pads, key overall performance benefits, and why it outperforms different geomembrane material options. By grasp its position in these crucial mining operations, you can make certain compliance, shield ecosystems, and keep operational efficiency.

Why Impervious Geomembrane Is Non-Negotiable in Mining Containment

Mining things to do existing two main containment challenges: tailings (waste rock and mineral residues) and heap leach options (chemical-laden fluids used to extract metals). Both demand impenetrable geomembrane liners to stop seepage into groundwater, soil, or close by waterways—contamination that should result in regulatory fines, ecological damage, and reputational harm. Geomembrane material acts as a barrier, containing these substances whilst enabling managed management, such as dewatering tailings or accumulating leachate.

Not all geomembrane cloth can face up to mining’s harsh conditions. Tailings are abrasive, acidic, and heavy; heap leach options comprise corrosive chemical substances like cyanide or sulfuric acid. This calls for a liner with magnificent strength, chemical resistance, and impermeability—qualities that hdpe geomembrane grants consistently. Its special homes make it the enterprise preferred for mining containment, outperforming choices like PVC or EPDM in sturdiness and long-term reliability.

HDPE Geomembrane in Tailings Ponds: Safe Waste Containment

Tailings ponds are giant reservoirs the place mining byproducts are saved and dewatered. Without perfect lining, poisonous metals (such as lead or mercury) and acidic fluids can leach into the environment. Hdpe geomembrane offers a strong solution, serving as each principal and secondary liners to make certain zero seepage.

Key Advantages for Tailings Pond Use

1. Abrasion Resistance: Tailings are extraordinarily abrasive, however hdpe geomembrane’s dense molecular shape and thick gauge face up to tearing and wear. Even underneath the weight of saturated tailings, the liner continues its integrity, stopping punctures from rocks or debris.

2. Chemical Inertness: Acid mine drainage (AMD), a frequent byproduct of tailings, includes sulfuric acid and heavy metals. Hdpe geomembrane is inert to these substances, averting degradation that ought to create seepage paths. Unlike PVC liners, which may additionally swell or spoil down in acidic environments, HDPE stays steady for decades.

3. Superior Impermeability: As an impenetrable geomembrane, HDPE has extraordinarily low permeability, making sure even minute quantities of fluid do now not ignore through. This protects groundwater and floor water from contamination, a crucial aspect in environmental compliance.

Tailings Pond Installation Best Practices

Installing hdpe geomembrane in tailings ponds requires precision to keep away from seams or vulnerable points. Heat fusion welding (hot wedge or extrusion) is the favored method, growing molecular bonds between liner sheets that suit the membrane’s strength. An underlayment of non-woven geotextile protects the HDPE from sharp rocks in the pond base. Proper anchoring alongside the perimeter prevents transferring as tailings are added, maintaining the liner taut and intact.

HDPE Geomembrane in Heap Leach Pads: Boosting Extraction Efficiency

Heap leach pads are engineered surfaces the place overwhelmed ore is piled, and chemical options are sprayed to extract metals like gold or copper. The liner’s position is dual: include the leach answer to maximize metallic restoration and stop contamination. Hdpe geomembrane excels in both, making it imperative for heap leach operations.

What Makes HDPE Ideal for Heap Leach Pads

1. Efficient Leachate Collection: Hdpe geomembrane presents a smooth, tightly closed floor that lets in leachate (metal-rich solution) to drift freely into series ditches or pipes. This maximizes steel recovery, as no answer is misplaced to seepage. Its easy texture additionally prevents ore particles from adhering, decreasing clogging and maintenance.

2. Chemical Resistance to Leach Solutions: Heap leach options regularly include cyanide, ammonia, or acidic agents. Hdpe geomembrane resists degradation from these chemicals, making sure the liner doesn’t advance pores or cracks that ought to leak poisonous fluids. This balance is fundamental for each environmental compliance and operational efficiency—leaks suggest misplaced steel and luxurious cleanup.

3. UV and Weather Durability: Heap leach pads are uncovered to the elements, however HDPE is infused with UV stabilizers in the course of manufacturing. This prevents photo-oxidation (brittleness from sunlight) and ensures the liner keeps power in severe temperatures, from warm deserts to bloodless mountain mines.

Heap Leach Pad Liner Design Features

Heap leach pad liners regularly use a “double liner” system: a principal hdpe geomembrane at once below the ore heap, and a secondary liner under with leak detection sensors. This redundancy offers an more layer of protection, alerting operators to seepage earlier than it turns into a problem. The liner is additionally sloped to facilitate leachate flow, with collection factors strategically positioned to optimize steel recovery.

HDPE Geomembrane vs. Other Geomembrane Fabric Options

While different geomembrane material exists, hdpe geomembrane is the clear mining preference due to its unmatched property combination:

Longevity: Properly established HDPE liners ultimate 30+ years, outperforming PVC (10–15 years) and EPDM (15–20 years). This reduces alternative prices and long-term environmental risk.Cost-Effectiveness: Though upfront charges may also be higher, HDPE’s low upkeep and lengthy lifespan make it greater least expensive over time. It also requires fewer repairs, minimizing operational downtime.Environmental Safety: As an tightly closed geomembrane, HDPE prevents contamination, assisting mines meet rules like the Clean Water Act. Its inert nature skill no damaging chemical leaching.

Conclusion: HDPE Geomembrane—The Backbone of Safe Mining Containment

In tailings ponds and heap leach pads, hdpe geomembrane is extra than a liner—it’s a indispensable aspect of accountable mining. Its impermeability, chemical resistance, and sturdiness make sure mining byproducts and technique options are contained safely, defending ecosystems and making sure regulatory compliance. As an invulnerable geomembrane, it outperforms different geomembrane cloth options, turning in long-term reliability and price savings.

For mining operations balancing effectivity with environmental stewardship, hdpe geomembrane is the gold standard. Whether containing abrasive tailings or corrosive leach solutions, it presents peace of idea that seepage won’t occur—safeguarding the planet, community, and your mining project’s success. Invest in HDPE liners, and construct a containment machine that lasts as lengthy as your operation.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province