How to Choose the Right HDPE Geomembrane for Your Project: A Complete Buying Guide

Choosing the right hdpe geomembrane is a indispensable selection that without delay affects your project’s durability, performance, and long-term success. Whether you’re working on a landfill, water reservoir, agricultural irrigation system, or industrial containment project, the proper geomembrane acts as a dependable barrier in opposition to leaks, environmental damage, and expensive repairs. With infinite preferences available, navigating the determination technique can be overwhelming—but this information breaks down the key elements to consider, making sure you make investments in a hdpe geomembrane that aligns with your project’s special needs.

1. Understand the Core Properties of HDPE Geomembrane

To pick out the pleasant geomembrane, begin by means of gaining knowledge of the necessary traits that outline hdpe geomembrane performance. These residences decide how properly the fabric will stand up to your project’s conditions, so by no means pass by this foundational step.

Thickness: Match to Project Demands

HDPE geomembrane thickness levels from 0.5mm to 3.0mm+, and choosing the proper gauge is non-negotiable—thin geomembrane (0.5–1.0mm) fits brief initiatives like small ponds or momentary containment, whilst thicker selections (1.5–3.0mm) are obligatory for high-stress functions such as landfills, mining tailings, and giant water storage facilities, the place the hdpe geomembrane have to withstand punctures from rocks, heavy equipment, and long-term pressure, and it’s critical to reference enterprise requirements for your task kind as most engineering specs specify minimal thickness to make sure structural integrity.

Density & Material Grade

HDPE (High-Density Polyethylene) geomembrane derives its power from a density vary of 0.941–0.965 g/cm³, which can provide most efficient tensile strength, tear resistance, and impermeability in contrast to low-density alternatives, and when selecting, seem for hdpe geomembrane graded by way of resin type—Grade 1 (HDPE 3000) is best for normal use, Grade two (HDPE 4000) presents more desirable pressure for harsh environments, and for initiatives uncovered to chemical compounds or severe temperatures, distinctiveness grades like UV-stabilized or chemical-resistant geomembrane are vital to stop untimely degradation.

Impermeability & Chemical Resistance

The principal reason of any geomembrane is to create a barrier, so impermeability is non-negotiable, and hdpe geomembrane excels right here with extraordinarily low permeability to water, oils, and most chemicals, making it ideal for industrial containment, wastewater treatment, and landfill liners; when evaluating options, verify the hdpe geomembrane’s chemical resistance ranking to make certain it can stand up to unique resources in your mission (e.g., acids, solvents, or agricultural chemicals) and keep away from cloth breakdown and leaks.

2. Assess Your Project’s Specific Requirements

No two tasks are the same, so the proper hdpe geomembrane should be tailor-made to your special conditions. Start through answering key questions about your application, environment, and long-term goals.

Application Type

Different makes use of demand exceptional geomembrane features: for water conservation tasks like reservoirs, ponds, and canals, prioritize hdpe geomembrane with excessive flexibility and UV resistance, the place 1.0–1.5mm thickness works for small ponds and 1.5–2.0mm for massive reservoirs; for waste administration such as landfills and hazardous waste sites, select thick (2.0–3.0mm) hdpe geomembrane with chemical resistance and puncture safety that meets EPA or neighborhood landfill liner standards; for agriculture functions like irrigation and aquaculture, decide for light-weight however long lasting geomembrane (0.75–1.2mm) that resists root penetration and UV damage, with food-safe hdpe geomembrane a need to for aquaculture or crop irrigation; and for industrial containment like chemical storage and mining, pick out strong point hdpe geomembrane with superior chemical resistance and excessive tensile energy to face up to heavy masses and corrosive substances.

Environmental Conditions

Your project’s area and local weather will dictate indispensable geomembrane traits: bloodless areas require hdpe geomembrane with exact low-temperature flexibility to keep away from brittleness in freezing weather, whilst warm climates want strong UV stabilization to forestall sun-induced cracking; rocky or uneven terrain needs thicker, extra puncture-resistant geomembrane, and whilst clay-rich soils can also require extra geotextile underlays, a remarkable hdpe geomembrane stays the major barrier; tasks with excessive water stress (e.g., dams or deep ponds) need hdpe geomembrane with excessive burst electricity and seam integrity to forestall leaks.

Project Lifespan

Temporary tasks (1–5 years) can use trendy hdpe geomembrane, however long-term initiatives (10+ years) require top rate materials, so make investments in geomembrane with fantastic resins and UV stabilizers—these might also price extra upfront however decrease upkeep and alternative fees over time—and for everlasting infrastructure, confirm the hdpe geomembrane’s projected provider lifestyles with the producer to make certain it aligns with your project’s sturdiness goals.

3. Verify Product Quality & Manufacturer Credentials

Not all hdpe geomembrane is created equal—poor-quality merchandise lead to leaks, challenge delays, and high-priced repairs. Ensure you’re shopping for a dependable geomembrane by means of vetting each the product and the manufacturer.

Industry Certifications & Standards

Reputable hdpe geomembrane have to meet world or regional standards, so seem for certifications like ASTM D4321 (U.S. popular for geomembrane performance), GB/T 17643 (Chinese country wide standard), ISO 9001 (quality administration gadget certification for manufacturers), and EN 13361 (European popular for geomembrane used in civil engineering), as these certifications assurance the geomembrane has surpassed rigorous trying out for tensile strength, tear resistance, impermeability, and durability.

Third-Party Testing

Always ask for third-party take a look at reviews for the hdpe geomembrane you’re considering, as these assessments must confirm key residences which includes tensile power and elongation at break, puncture resistance, seam energy (critical for hdpe geomembrane considering the fact that seams are frequent leak points), and UV resistance (accelerated getting old assessments to simulate long-term solar exposure), and keep away from producers who can’t grant these reviews as they may also be promoting substandard geomembrane.

Manufacturer Experience & Reputation

Choose a producer with a demonstrated music file in producing hdpe geomembrane, prioritizing these with 5+ years of enterprise experience, case research or references from comparable projects, obvious manufacturing strategies (e.g., the usage of virgin resins as a substitute of recycled substances for integral applications), and responsive purchaser guide (including technical preparation for installation), as a legitimate producer will assist you pick out the proper geomembrane and tackle any troubles for the duration of or after installation.

4. Consider Installation & Long-Term Maintenance

Even the first-rate hdpe geomembrane will fail if set up incorrectly. Factor in set up necessities and protection wants to make certain your project’s success.

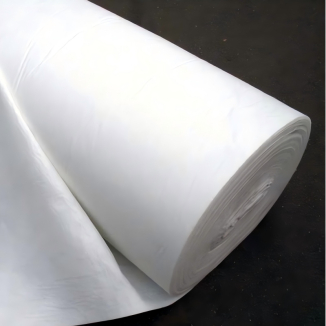

Size & Seam Compatibility

HDPE geomembrane is normally offered in rolls, so pick out roll sizes that decrease seams (since seams are the weakest points)—for giant projects, choose for wider rolls (e.g., 6–8 meters wide) to minimize the range of joints—and make sure the hdpe geomembrane is well suited with your welding gear (most hdpe geomembrane requires thermal welding) via confirming the material’s weldability with the manufacturer, and appoint skilled installers who specialize in geomembrane welding to make certain strong, leak-proof seams.

Installation Requirements

Consider the realistic factors of putting in your hdpe geomembrane: rocky or sharp terrain requires a geotextile underlay to shield the geomembrane from punctures, and pairing hdpe geomembrane with the right underlayment extends its lifespan; the geomembrane need to be securely anchored to stop shifting, with picks consisting of trench anchoring, weighted edges, or mechanical fasteners chosen primarily based on your project’s design; and keep away from dragging or losing hdpe geomembrane rolls as this can harm the material, following the manufacturer’s dealing with suggestions to stop tears or punctures earlier than installation.

Maintenance & Durability

A satisfactory hdpe geomembrane requires minimal maintenance, however ordinary inspections are key—look for geomembrane that’s convenient to look into and repair, as small tears or punctures have to be fixable with patch kits—and keep away from merchandise inclined to cracking or fading that will require general repairs, additionally, select hdpe geomembrane that resists mold, mildew, and rodent injury to minimize long-term preservation fees and make certain steady performance.

5. Balance Budget & Long-Term Value

While price is a factor, don’t sacrifice best for a decrease price. Cheap geomembrane can also retailer cash upfront however will possibly fail prematurely, main to steeply-priced leaks and rework. Instead, focal point on value: a exceptional hdpe geomembrane can also have a greater preliminary price however gives longer carrier life, fewer repairs, and higher performance.

Compare costs from a couple of manufacturers, however make sure you’re evaluating apples to apples—consider elements like thickness, cloth grade, certifications, and warranty. Look for hdpe geomembrane with a manufacturer’s assurance (5–10 years is standard) to defend your investment. Remember, the most inexpensive alternative is not often the great when it comes to geomembrane—your project’s success relies upon on a dependable barrier.

Final Thoughts: Choose Wisely for Project Success

Selecting the proper hdpe geomembrane requires a stability of appreciation fabric properties, assessing task needs, verifying quality, and planning for installation. By following this guide, you’ll keep away from frequent pitfalls and make investments in a geomembrane that offers durability, impermeability, and long-term value. Whether you’re working on a small agricultural task or a large-scale industrial containment system, the proper hdpe geomembrane is the basis of a successful, leak-free project.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province