Maximizing Efficiency: Best Practices for Geotube Dewatering Performance.

Introduction: The Power of Geosynthetic Dewatering Technology

In the world of sediment management, sludge treatment, and environmental remediation, Geosynthetic Tubes have revolutionized how we cope with difficult dewatering tasks. These engineered containers offer a cost-effective, efficient, and environmentally sound alternative to standard techniques like mechanical presses or settling ponds. The core process, known as Geotube Dewatering, involves pumping slurry into high-strength cloth containers that continue fine solids while permitting easy water to drain out.

However, the journey from a simple setup to a high-performance dewatering operation is no longer automatic. The efficiency, speed, and ultimae quantity reduction performed through Geotube Dewatering are without delay tied to the implementation of proven pleasant practices. This comprehensive information delves into the critical steps and techniques for maximizing the performance of your Dredging and Dewatering Bags system, making sure you get the most out of this powerful technology.

Understanding the Geotube Dewatering Process

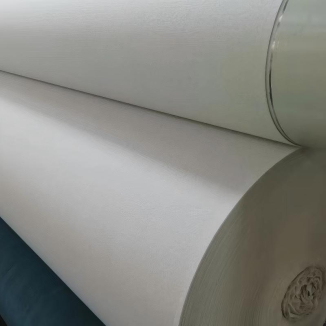

Before optimizing, it is crucial to understand the mechanics. Geosynthetic Tubes are generally made from UV-stabilized, high-strength polypropylene fabric. The fabric's weave is engineered to have unique filtration characteristics: small enough to retain nice strong particles, but porous enough to permit water to get away under pressure.

The Geotube Dewatering process follows a cyclical pattern:

Filling: Sludge or sediment slurry is pumped into the Dredging and Dewatering Bags.

Dewatering: Water begins to exude via the fabric pores, while solids are retained within.

Consolidation: The retained solids consolidate under their very very own weight and the pressure from subsequent filling cycles, further releasing water.

Curing: Once filling is complete, the dewatered solids continue to dry and harden, carrying out a stable, stackable material.

Maximizing efficiency means accelerating and enhancing each and every of these stages.

Best Practice : Comprehensive Site and Sludge Characterization

The foundation of an efficient Geotube Dewatering project lies in understanding the material you are dealing with. A one-size-fits-all approach is a recipe for subpar performance.

Key Actions:

Conduct Jar Testing: Simple jar tests can provide initial insights into settling rates and potential polymer requirements.

Perform Particle Size Analysis: The distribution of particle sizes in the slurry is the single most fundamental factor. Finer particles like clays and silts dewater slower than sands and require different strategies.

Determine Solid Content: Know the percentage of solids in your incoming slurry. This is essential for sizing your Geosynthetic Tubes and calculating mission timelines.

Analyze Chemistry: Assess the pH and chemical composition of the water. This can significantly impact the effectiveness of flocculants, a key component for optimizing Geotube Dewatering.

Why it Matters for Geosynthetic Tubes: A well-characterized sludge lets in for specific engineering of the entire system, from fabric pore dimension selection to polymer kind and dosage, setting the stage for a profitable dewatering operation.

Best Practice : The Art and Science of Polymer Selection and Dosing

This is arguably the most critical component for maximizing efficiency in Geotube Dewatering. Polymers, or flocculants, act as binding marketers that cause satisfactory particles to clump together into large flocks. These larger flocks drain water extra efficiently and are much less in all likelihood to clog the pores of the Geosynthetic Tubes.

Key Actions:

Perform Laboratory Testing: Don't guess. Conduct bench-scale tests (beaker tests) with different anionic, cationic, and non-ionic polymers to pick out the most nice type for your specific sludge.

Optimize Dosage: Too little polymer effects in negative flocculation and cloudy effluent. Too much polymer can create a slimy, stable gel that hinders dewatering and can blind the cloth pores. Find the "sweet spot."

Ensure Proper Mixing and Injection: The polymer ought to be properly hydrated and injected into the slurry stream at a factor that approves for complete mixing and floc formation before it enters the Dredging and Dewatering Bags. Inadequate mixing leads to inefficient polymer use.

Monitor and Adjust Continuously: Slurry traits can change. Continuously screen the floc formation and clarity of the effluent, and be prepared to alter the polymer dose or type as needed.

Why it Matters for Geotube Dewatering: Proper polymer use dramatically will increase dewatering speed, improves effluent clarity, maximizes solids retention, and ultimately leads to a greater final solids content material and greater quantity reduction inside your Geosynthetic Tubes.

Best Practice : Strategic Filling and Operational Techniques

How you fill the containers is just as necessary as what you put in them. A disciplined filling strategy prevents frequent issues like short-circuiting and uneven solids distribution.

Key Actions:

Implement a Sequential Filling Cycle: Avoid non-stop filling. Use a cycle of filling followed by means of a rest length (e.g., fill for 2 hours, relaxation for 4-6 hours). This allows time for fantastic dewatering and consolidation to occur earlier than adding greater load, which is crucial for the long-term overall performance of Dredging and Dewatering Bags.

Use Multiple Injection Points: For long Geosynthetic Tubes, use a number of inlet ports along the length. This promotes even solids distribution and prevents one location from becoming overloaded whilst others remain empty.

Control Fill Pressure: Monitor the pump pressure. A surprising spike in pressure can point out that the fabric pores are turning into blinded. If this occurs, stop filling and permit more time for dewatering.

Manage the Water Level: In a multi-tube setup, think about the height of the decant water between tubes. Managing this can assist use the upper layers of the cloth for further filtration.

Why it Matters for Geosynthetic Tubes: A strategic filling method ensures that the entire quantity of the Geotube Dewatering unit is utilized effectively, prevents structural overloading, and minimizes the risk of pore blinding, main to faster general project completion.

Best Practice : Effluent Quality Management and Monitoring

The readability of the water discharged from the Geosynthetic Tubes is a direct indicator of the health and efficiency of the dewatering process.

Key Actions:

Conduct Regular Turbidity Testing: Use a turbidity meter to quantitatively measure the readability of the effluent. This presents an objective measure of performance.

Visually Inspect Effluent: Regularly check for the presence of solids carry-over. Cloudy effluent suggests negative flocculation and may require polymer adjustment.

Implement a Containment/Recirculation System: Have a contingency plan, such as a small holding pond or sump, to include and, if necessary, recirculate effluent that does now not meet discharge standards. This is a critical part of accountable administration for any Geotube Dewatering project.

Why it Matters for Geotube Dewatering: Proactive effluent management ensures environmental compliance, protects your site from runoff issues, and provides real-time remarks for optimizing polymer dosing and fill rates for your Dredging and Dewatering Bags.

Best Practice : Planning for the Curing and Handling Phase

The job isn't over when the tube is full. The final curing phase is essential for achieving the highest manageable solids content and creating a material that is handy to handle and dispose of or reuse.

Key Actions:

Allow Ample Curing Time: Once filling is complete, leave the Geosynthetic Tubes in place for a number of weeks or even months, depending on climate and material. Evaporation and continued consolidation will in addition beef up the contained solids.

Consider Slitting for Access: For some projects, slitting the fabric open after sufficient curing can expose the solids to air and considerably speed up the drying process.

Plan for Final Disposition: Have a clear plan for the dewatered solids. Will they be landfilled, used as daily cover, or beneficially reused as soil amendment? Knowing the give up purpose will help determine the required ultimate solids content.

Why it Matters for Geosynthetic Tubes: Proper curing maximizes quantity reduction, which directly translates to decrease hauling and disposal costs. It transforms a liquid sludge into a stable material, simplifying the final stage of the Geotube Dewatering process.

Conclusion: Integrating Best Practices for Optimal Results

Maximizing the efficiency of your Geotube Dewatering operation is now not about a single magic bullet. It is a holistic method that integrates careful planning, scientific optimization, and disciplined execution. From the initial sludge characterization to the last curing of the Dredging and Dewatering Bags, every step builds upon the last.

By investing time in proper polymer selection, implementing a strategic filling cycle, and continually monitoring performance, you can seriously change your Geosynthetic Tubes from a simple container into a high-performance dewatering system. This approach minimizes mission duration, reduces operational costs, ensures environmental compliance, and delivers the fantastic results that make Geotube Dewatering such a treasured technology for a wide vary of industries. Remember, effectivity is earned through attention to detail.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province