Woven vs. Non-Woven Geotextiles: Key Differences and When to Use Each

When planning a growing or landscaping project, one of the most critical yet often left out elements is the geotextile. These fabric workhorses lie beneath the surface, performing integral aspects like separation, filtration, drainage, and reinforcement. However, choosing the wrong structure can lead to assignment failure, costly repairs, and significant headaches. The primary division in this world is between woven and non-woven geotextiles. Understanding their key variants is not just a technicality—it's essential to your project's success and longevity.

This whole guide will unravel the complexities of woven and non-woven geotextiles. We'll explore their manufacturing processes, inherent properties, and high-quality applications, empowering you to make an educated decision. Whether your project involves reinforcing a steep embankment or making fine perfect drainage behind a retaining wall, this article will be your definitive resource.

Understanding Geotextiles: The Hidden Heroes of Construction

Before diving into the differences, let's set up what geotextiles are. These are permeable synthetic fabrics, oftentimes made from polypropylene or polyester, used in contact with soil, rock, or any other geotechnical material. Their fundamental elements are:

Separation: Preventing the mixing of two top notch soil layers, such as a soft subsoil and a gravel base, thereby keeping the structural integrity of both.

Filtration: Allowing water to pass via using through while stopping soil particles from migrating, which prevents clogging and erosion.

Drainage: Facilitating the float of water inside the plane of the fabric, relieving hydrostatic pressure.

Reinforcement: Adding tensile power to the soil, enabling the building of steeper, extra stable slopes and embankments.

The desire between woven and non-woven fabric at as soon as impacts how properly these features are performed.

Woven Geotextiles: The High-Strength Solution

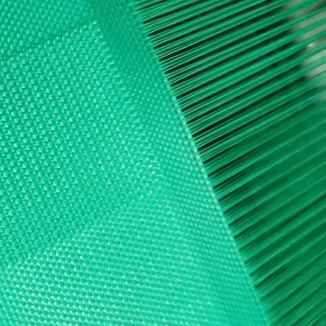

Woven geotextiles are manufactured the utilization of a process comparable to that of traditional textiles. Individual threads, recounted as yarns or tapes, are interlaced in two guidelines (warp and weft) on a loom. This creates a robust, dimensionally secure fabric with a very distinct, cloth-like appearance.

Key Characteristics of Woven Geotextiles:

High Tensile Strength: Their major advantage. The interlocking yarns create a material with gorgeous load-bearing capacity, making them ideal for reinforcement applications.

Low Elongation: They have minimal stretch below load, presenting outstanding dimensional stability and confinement.

Robust Separation: Their immoderate energy and puncture resistance make them extremely good for putting apart dissimilar soils, even under heavy heaps and dynamic stress.

Permeability and Filtration: While they are permeable, their go with the flow rate is generally minimize than that of non-woven geotextiles. Their filtration houses are excellent for certain soil types, as the unique pore dimension can be engineered.

Primary Applications of Woven Geotextiles:

The inherent electrical energy of woven geotextiles makes them the go-to choice for demanding, high-load scenarios.

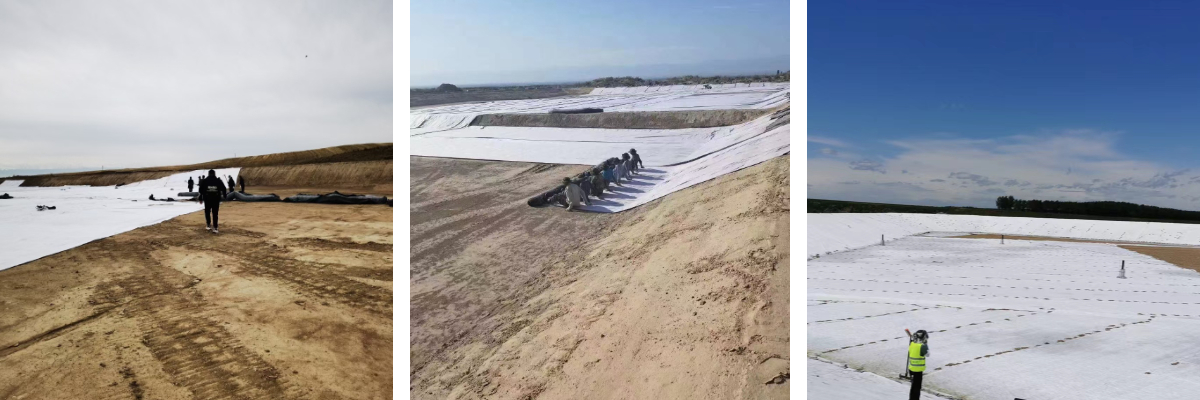

1. Embankment Reinforcement Woven Geotextile

One of the most necessary features is in the improvement of embankments over soft, unstable subgrades. An Embankment Reinforcement Woven Geotextile is placed at the base of the embankment. It distributes the load over a wider area, lowering differential settlement and stopping the embankment fill from punching into the tender soil below. This creates a secure platform and drastically will increase the typical steadiness of the structure.

2. Slope Stabilization Woven Geotextile

When constructing reinforced soil slopes or repairing failing herbal slopes, a Slope Stabilization Woven Geotextile is used. The material is placed in layers between the soil lifts. The immoderate tensile power of the fabric interacts with the soil through friction, developing a coherent, bolstered mass that can stand at plenty steeper angles than unreinforced soil. This utility is necessary for building space-saving partitions and shoring up eroding hillsides.

3. Road and Pavement Base Reinforcement

Beneath roads and parking lots, woven geotextiles act as a stable separation layer, stopping the aggregate base path from mixing with the subgrade. This maintains the thickness and integrity of the base layer, extending the pavement's lifestyles and reducing rutting.

4. Railroad Track Bed Stabilization

They are used to separate the ballast from the subgrade, stopping fouling and preserving track alignment beneath the superb cyclic masses of train traffic.

Non-Woven Geotextiles: The Versatile Filter and Drainage Layer

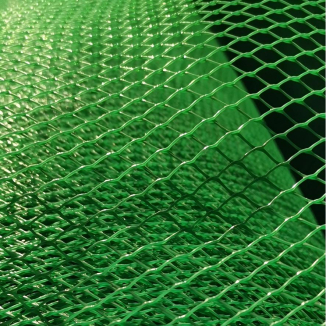

Non-woven geotextiles are manufactured thru a mechanical, thermal, or chemical bonding method (or a combination), as an alternative than weaving. The most common technique is needle-punching, the region a internet of continuous filament or staple fibers is entangled the use of barbed needles. This effects in a thick, felt-like fabric.

Key Characteristics of Non-Woven Geotextiles:

High Permeability and Flow Rate: Their random, fibrous shape creates a vast community of interconnected pores, permitting water to bypass through effortlessly in the airplane of the material and through it.

Excellent Filtration: They are best for stopping soil piping even as allowing groundwater to drift freely, making them ideal for drainage applications.

Puncture Resistance: Their thick, fuzzy structure provides superb safety for state-of-the-art liners, like those in landfills or ponds.

Elongation: They are greater extensible than woven geotextiles, permitting them to conform to uneven subgrades.

Primary Applications of Non-Woven Geotextiles:

The final drainage and filtration capabilities of non-woven geotextiles make them appropriate for a distinctive set of challenges.

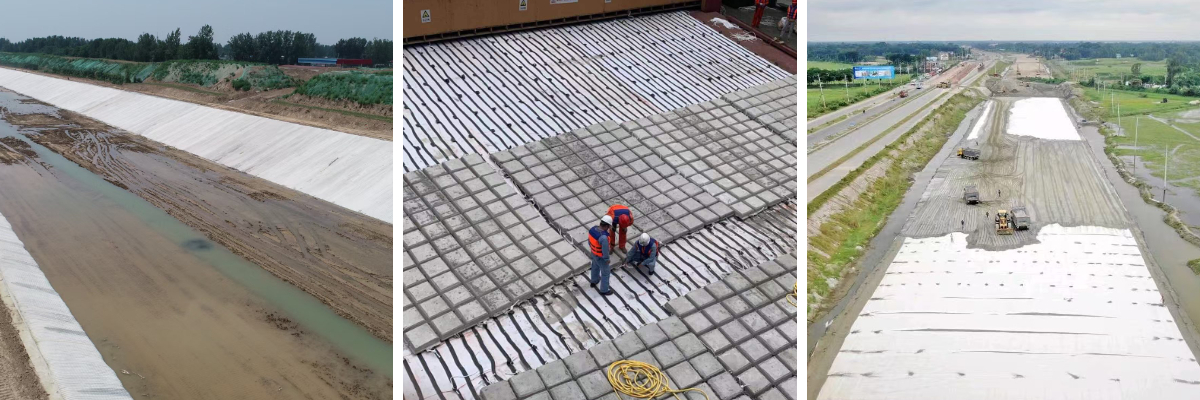

1. Drainage Applications

This is their strongest suit. They are used at the decrease back of holding walls, in French drains, and around subsurface drainage pipes. The fabric wraps the combination drain, performing as a filter that keeps high-quality soil particles from clogging the drain at the identical time as permitting water to enter freely. In many projects, a PP geotextile of the non-woven variety is distinct for this very cause due to its chemical resistance and durability.

2. Asphalt Overlay Stress Relief

A thin non-woven geotextile is often saturated with asphalt and used as an interlayer between historic and new pavement. It acts as a waterproofing barrier and helps to retard reflective cracking from the historic pavement into the new overlay.

3. Protection for Geomembranes

In landfill liners, pond liners, and different containment applications, a thick non-woven geotextile is placed above and under the geomembrane. It cushions and protects the refined liner from puncture by way of sharp rocks or debris in the subgrade or cowl soil.

4. Erosion Control

Under rip-rap (rock armor) on slopes and shorelines, a non-woven geotextile acts as a filter, preventing underlying soil from being washed out with the aid of the rock whilst permitting water pressure to dissipate.

Head-to-Head Comparison: Woven vs. Non-Woven

While we retain away from tables, a direct evaluation of their core residences is essential.

Strength: Woven geotextiles are the undisputed champions of tensile strength. If your project involves defending soil at the same time beneath tension, a woven fabric is mandatory. For an Embankment Reinforcement Woven Geotextile, this immoderate electricity is non-negotiable.

Permeability/Drainage: Non-woven geotextiles provide superior water flow, every through and inside the fabric. For drainage behind a wall, a non-woven PP geotextile will function a lengthy way greater effectively.

Filtration: Both can filter, but their mechanisms differ. Woven geotextiles have more defined, sieve-like pore openings, which can be best for positive granular soils. Non-wovens have a more tortuous path, which is excellent for defending finer, cohesive soils.

Elongation: Woven geotextiles are stiff and have low elongation. Non-wovens are greater flexible and can stretch to conform to irregular surfaces.

When to Use Each: Your Project Decision Guide

Making the suited choice boils down to the principal function you desire the geotextile to perform.

Choose a WOVEN Geotextile if your mission involves:

Reinforcement: Any software where the soil needs delivered tensile strength. This is the defining use for a Slope Stabilization Woven Geotextile or an Embankment Reinforcement Woven Geotextile.

High-Stability Separation: Under heavy-load get entry to roads, parking lots, and foundation bases the location the essential intention is to prevent mixture loss and subsoil infection below severe loading.

Choose a NON-WOVEN Geotextile if your undertaking involves:

Drainage and Filtration: Any utility where water go with the glide is the primary concern, such as in French drains, in the decrease back of conserving walls, or beneath seepage series systems. A non-woven PP geotextile is the stylish here.

Protection: Cushioning and defending geomembranes from puncture.

Asphalt Overlays: As a stress-relieving interlayer to combat reflective cracking.

Conclusion: The Right Fabric for the Right Job

There is no "better" geotextile—only the desirable one for your unique application. The desire between woven and non-woven is a functional one, dictated through way of the soil mechanics and hydrological wants of your site.

To recap: Use woven for power and stability. When you need to decorate a slope, stabilize an embankment, or separate layers underneath heavy, dynamic loads, the excessive tensile strength of a woven geotextile is indispensable. Use non-woven for drainage and filtration. When your mission consists of managing water flow, relieving pressure, and defending liners, the superior permeability of a non-woven material is the clear winner.

By cautiously assessing your project's necessities and matching them to the inherent houses of these two geotextile types, you can ensure a stable, durable, and rewarding outcome. Always seek recommendation from with geotechnical engineers and material specifications to finalize your selection, on the other hand with this knowledge, you are now geared up to ask the proper questions and make a confident, informed decision.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province