Fire Resistance and Thermal Insulation Properties of Concrete Impregnated Fabric

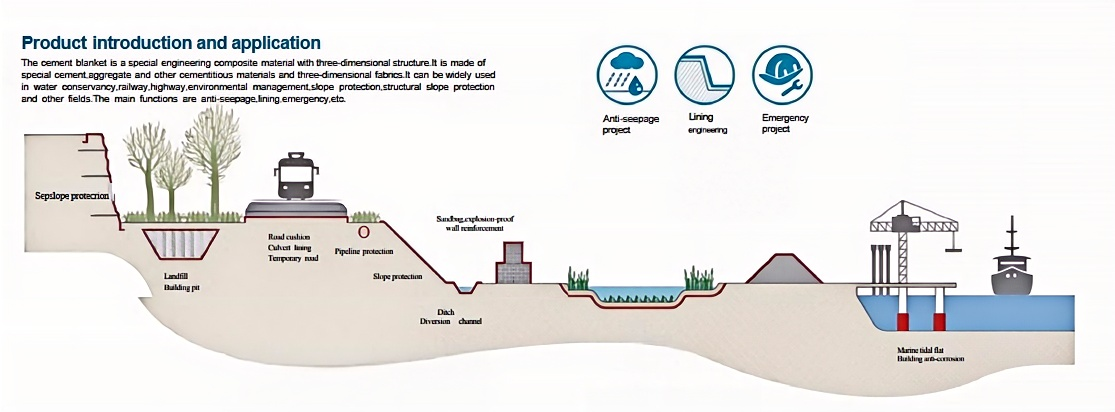

In development and emergency response, substances that mix flexibility with hearth protection are invaluable. Concrete impregnated fabric—a modern composite of fabric reinforcement and dry concrete mix—has emerged as a game-changer, providing splendid hearth resistance and thermal insulation alongside its signature adaptability. Unlike regular inflexible concrete or flammable artificial fabrics, this fabric gives a sturdy barrier towards warmness and flames whilst conforming to irregular surfaces. This information explores the science at the back of the furnace resistance and thermal insulation of concrete impregnated fabric, highlighting how concrete material material and Flexible Concrete Blanket versions supply these imperative properties. We’ll additionally study real-world purposes the place these qualities make a life-saving difference, supporting you recognize why this fabric is turning into a staple in fire-prone environments.

The Science of Fire Resistance in Concrete Impregnated Fabric

Concrete impregnated cloth owes its furnace resistance to its special composition: a fabric matrix infused with a dry concrete combine (typically Portland cement, aggregates, and additives). When activated with water, the concrete hardens into a dense, inert layer that acts as a hearth barrier. Unlike natural substances (wood, artificial fabrics) that burn or soften when uncovered to flames, concrete is non-combustible—meaning it doesn’t ignite, launch poisonous fumes, or make a contribution to fireplace spread.

The fabric reinforcement (often made of glass fiber or polyester) performs a secondary however necessary role. While the concrete offers the most important fireplace resistance, the material holds the concrete in vicinity at some stage in and after publicity to excessive temperatures. Even if the outer layer of concrete chars barely (a uncommon incidence at regular furnace temperatures), the cloth matrix prevents the fabric from crumbling, retaining a non-stop furnace barrier. This aggregate of non-combustible concrete and heat-resistant cloth makes concrete material material a ways extra fire-safe than common development textiles.

How Concrete Impregnated Fabric Delivers Thermal Insulation

Thermal insulation is the potential to gradual warmth transfer, and concrete impregnated material excels at this thanks to its composite structure. When hardened, the fabric types a dense but porous layer: the concrete matrix traps air inside its pores, and the cloth fibers create extra air pockets. Air is a terrible conductor of heat, so these trapped air areas act as insulation, decreasing the switch of warmth from one aspect of the cloth to the other.

Flexible Concrete Blanket versions decorate this insulation impact further. Their flexible, layered diagram lets in for a thicker concrete layer (when activated) besides sacrificing maneuverability. Thicker layers imply greater air pockets and a increased barrier to warmth transfer—making them best for functions the place thermal safety is critical, such as wrapping pipes or insulating structural elements. Unlike inflexible insulation substances (e.g., foam boards), Flexible Concrete Blanket can conform to curved or uneven surfaces, ensuring whole insurance and steady insulation.

Key Properties Enhancing Fire and Thermal Performance

Manufacturers engineer concrete impregnated material with precise residences to enhance its furnace resistance and thermal insulation, tailoring it to worrying applications:

1. High-Temperature Stability

The concrete combine in concrete material material is formulated to face up to excessive temperatures barring decomposing. Portland cement, the predominant binder, retains its power at temperatures nicely above traditional constructing fires. Some versions consist of heat-resistant aggregates (e.g., vermiculite or perlite) that extend when heated, growing an even extra insulating layer. This high-temperature steadiness ensures the cloth doesn’t crack or spall beneath heat, keeping its hearth and thermal barrier properties.

2. Low Thermal Conductivity

Thermal conductivity measures how properly a fabric transfers heat, and concrete impregnated material has low thermal conductivity in contrast to inflexible concrete. This is due to the air pockets created by means of the material matrix and porous concrete. A decrease thermal conductivity capability warmth strikes via the cloth greater slowly, making it an fine insulator for each warm and bloodless environments—whether defending buildings from hearth warmth or maintaining warmth in industrial pipes.

3. Toxic Fume Resistance

A essential security characteristic of concrete impregnated material is its lack of poisonous fume emission when uncovered to fire. Unlike artificial fabric (e.g., polyester or nylon) that launch unsafe chemical compounds like carbon monoxide or dioxins when burned, the concrete and cloth factors of this cloth are inert. This makes it protected for use in enclosed areas or areas with human occupancy, as it doesn’t exacerbate fireplace dangers with poisonous smoke.

Real-World Applications of Fire-Resistant Concrete Impregnated Fabric

The fireplace resistance and thermal insulation of concrete impregnated material make it best for a vary of high-stakes applications:

1. Fire Barriers and Retardant Systems

In business and industrial buildings, concrete fabric material is used as a furnace barrier to separate booths and forestall fireplace spread. It can be utilized to walls, ceilings, or floors, forming a quick-to-install, non-combustible layer. For current structures, it’s an handy retrofitting answer to enhance fireplace protection barring most important renovations. In wildfire-prone areas, it’s used to wrap timber structural elements, defending them from embers and heat.

2. Emergency Fire Containment

Flexible Concrete Blanket is a staple in emergency response. Firefighters use it to create brief fireplace traces round wildfires, smothering flames and stopping spread. It’s additionally used to guard quintessential infrastructure (e.g., gasoline tanks, electricity transformers) throughout fires, as its rapid activation (just add water) and flexibility permit for fast deployment. Unlike usual hearth blankets, it doesn’t burn or melt, presenting long-lasting protection.

3. Industrial Thermal Insulation

In factories, refineries, and electricity plants, concrete impregnated cloth insulates pipes, tanks, and equipment that cope with high-temperature fluids or gases. Its bendy graph wraps round complicated pipe networks, lowering warmness loss and enhancing power efficiency. It additionally acts as a hearth barrier, defending close by gear from unintended fires. The material’s chemical resistance (a secondary benefit) makes it appropriate for harsh industrial environments the place different insulators degrade.

4. Construction of Fire-Safe Structures

For transient or everlasting buildings in fire-prone areas (e.g., development web site shelters, far off mining camps), concrete fabric material is used to construct walls, roofs, and floors. These constructions are fire-resistant, thermally insulated, and rapid to assemble—ideal for tasks the place security and velocity are priorities. They additionally stand up to weathering, making them long lasting in outside environments.

Why Concrete Impregnated Fabric Outperforms Traditional Materials

Compared to typical fire-resistant and insulating materials, concrete impregnated cloth affords special advantages:

Flexibility: Unlike inflexible concrete or ceramic insulation, it conforms to irregular surfaces, making sure whole coverage.

Quick Installation: Flexible Concrete Blanket prompts with water and hardens in hours, lowering set up time in contrast to pouring concrete or putting in inflexible insulation.

Portability: Dry rolls are light-weight and compact, making them handy to transport to far off or hard-to-reach sites.

Multi-Functionality: It combines hearth resistance, thermal insulation, and structural strength, doing away with the want for a couple of materials.

Conclusion: A Safe, Versatile Solution for Fire and Thermal Challenges

Concrete impregnated fabric—including concrete material cloth and Flexible Concrete Blanket—redefines furnace protection and thermal insulation in building and emergency response. Its special composite shape offers non-combustible furnace resistance, low thermal conductivity, and toxic fume-free performance, making it most appropriate to ordinary substances in many applications.

Whether you’re defending a constructing from wildfires, insulating industrial pipes, or deploying emergency hearth containment, this cloth gives the flexibility, speed, and reliability wanted to meet worrying challenges. As furnace dangers and power effectivity needs grow, concrete impregnated cloth is poised to emerge as an indispensable cloth for safe, sustainable, and resilient projects. Invest in this progressive solution, and you’ll attain a versatile device that safeguards lives, property, and the environment.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province