Key Considerations for Choosing the Right Geotextile Tube Material for Land Reclamation Projects

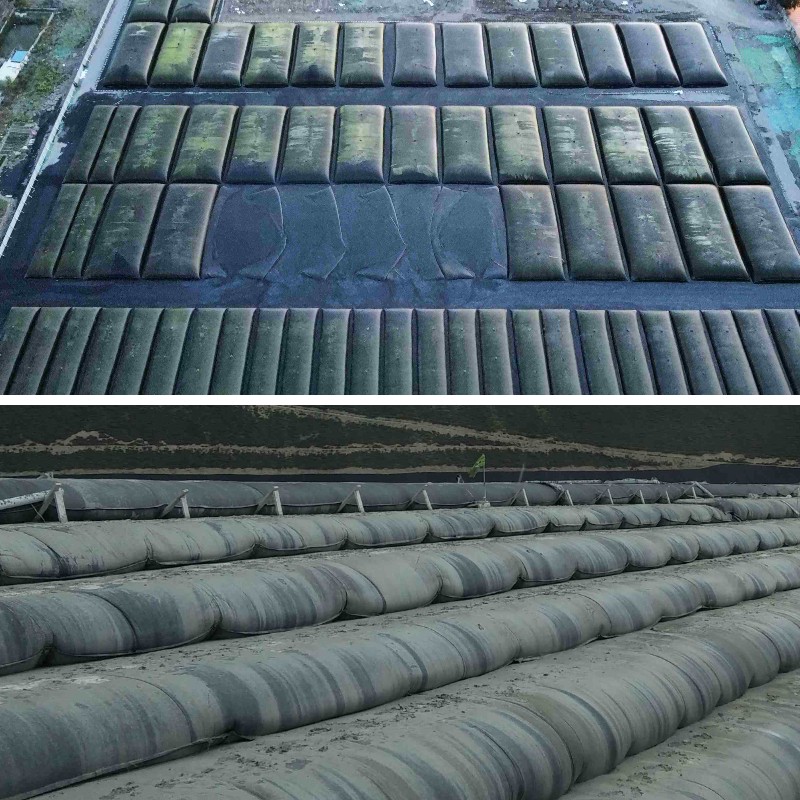

Land reclamation—turning coastal wetlands, dredged areas, or degraded land into usable space—relies closely on durable, high-performance geosynthetic solutions. Among these, Geotextile Tube (also acknowledged as geosynthetic tubes) stand out as low in cost tools: they are stuffed with dredged sediment, sand, or soil to shape steady barriers, speed up sedimentation, and form new landmasses. However, selecting the incorrect Geotextile Tube fabric can lead to catastrophic failures—such as tube rupture, untimely degradation, or terrible drainage—wasting time, budget, and undermining task sustainability. To make sure success, focal point on these 4 indispensable concerns when choosing Geotextile Tube substances for land reclamation.

1. Environmental Degradation Resistance: Ensuring Long-Term Service Life

Land reclamation tasks regularly span years (or decades) and expose geosynthetic tubes to harsh outside conditions: excessive UV radiation, corrosive soils, saltwater (for coastal projects), and microbial activity. A material’s capacity to withstand degradation at once affects the tube’s lifespan and the project’s long-term stability.

UV Radiation Resistance

Most Geotextile Tube substances are uncovered to daylight in the course of set up and service, and unprotected fabric wreck down rapidly beneath UV rays—becoming brittle, dropping strength, and subsequently tearing; this is mainly integral for coastal reclamation tasks with extended solar exposure, the place a UV-sensitive Geotextile Tube might also fail in 1–2 years (compared to 10+ years for UV-stabilized options), so you must appear for substances handled with UV stabilizers (e.g., carbon black or hindered amine mild stabilizers) that meet requirements like ASTM D4355, and for tropical regions, choose for a UV safety ranking of ≥70% retention of tensile electricity after 1,000 hours of UV exposure.

Chemical & Saltwater Corrosion Resistance

Land reclamation websites (especially coastal or industrial brownfield sites) regularly have acidic/alkaline soils or saltwater that can degrade sure Geotextile Tube materials—natural fibers (e.g., jute) or uncoated polyamide (nylon) dissolve or weaken in saltwater, whilst polyester (PET) or high-density polyethylene (HDPE) substances provide most useful resistance; for coastal reclamation, pick geosynthetic tubes made from PET or HDPE geotextiles (they face up to hydrolysis and salt crystallization), and for industrial brownfields, verify the material’s resistance to heavy metals or hydrocarbons the usage of supplier-provided chemical compatibility charts.

Biological Stability

Microorganisms (e.g., bacteria, fungi) in moist reclamation soils can decompose organic Geotextile Tube materials, main to structural failure, so you have to keep away from herbal fibers (e.g., cotton, jute) for wetland or freshwater reclamation and rather pick artificial substances like polypropylene (PP) or PET (inert to most soil microbes); for high-moisture sites, ask for substances handled with anti-microbial components to similarly minimize decomposition risks.

2. Mechanical Strength & Durability: Withstanding Project Stresses

Geotextile Tube substances need to undergo two sorts of stress: non permanent (during installation, filling, and handling) and long-term (from the weight of crammed sediment, water pressure, and wind/wave action). Inadequate energy leads to tube bulging, tearing, or collapse—halting reclamation progress.

Tensile Strength (Load-Bearing Capacity)

When crammed with sediment (weighing 1.5–2.0 lots per cubic meter), Geotextile Tubes stretch beneath interior load, so tensile energy (resistance to stretching) is non-negotiable; for large-scale reclamation (tubes ≥5 meters in diameter), the cloth need to have a minimal tensile energy of 15 kN/m (per ASTM D4632), whilst smaller tubes (2–3 meters) may additionally use 10–12 kN/m strength, and coastal reclamation initiatives with sand-filled geosynthetic tubes require greater tensile electricity (≥20 kN/m) to face up to wave affect and tidal pressure, not like inland tasks with lighter silt.

Tear & Puncture Resistance

During installation, Geotextile Tubes might also contact sharp objects (e.g., rocks, dredging equipment) or face surprising affects (e.g., falling sediment), and terrible tear/puncture resistance motives on the spot leaks; woven geotextiles (e.g., woven PP) provide higher tear resistance than non-woven preferences (interlocked fibers distribute stress effectively), so appear for a minimal tear electricity of three kN (per ASTM D4533), and for rocky soil sites, pick Geotextile Tube substances with a defensive coating (e.g., PVC or LDPE) to beautify puncture resistance.

Abrasion Resistance

Over time, geosynthetic tubes rub towards adjoining tubes, soil, or water-borne sediment, inflicting floor put on that weakens the cloth and exposes it to in addition degradation; take a look at the material’s abrasion resistance per ASTM D3884 (measures electricity retention after cyclic rubbing) and intention for ≥80% energy retention after 10,000 cycles, and in high-wind or high-current web sites (e.g., river deltas), select thicker geotextiles (≥200 g/m²) to reduce abrasion harm (thicker fabric have extra fiber mass to face up to wear).

3. Permeability & Filtration Performance: Balancing Drainage and Sediment Retention

A core characteristic of Geotextile Tube in land reclamation is to drain water from the stuffed sediment whilst holding stable particles (e.g., sand, silt). Poor permeability leads to waterlogging (making tubes heavy and unstable), whilst terrible filtration reasons sediment loss (reducing tube extent and polluting surrounding water).

Permeability Coefficient Matching

The Geotextile Tube’s permeability (water waft rate, measured as a k-value) have to in shape drainage needs—coastal reclamation makes use of geosynthetic tubes crammed with sand, requiring quickly drainage (k-value ≥1×10⁻³ cm/s) to expel saltwater and stabilize the tube, whilst inland wetland reclamation makes use of silt-filled tubes that want slower drainage (k-value ≤1×10⁻⁵ cm/s) to hold moisture for vegetation; keep away from over-permeability (k-value ≥1×10⁻² cm/s), as it motives excellent sediment loss, weakening the tube and polluting close by water.

Filtration Precision Control

The Geotextile Tube need to continue 90%+ of stuffed sediment particles (retention rate), which relies upon on pore measurement (O₉₀, the measurement keeping 90% of particles); for silt (average particle dimension 0.02 mm), the tube’s O₉₀ must be 0.05–0.1 mm (traps silt however drains water), and for sand (0.5–2 mm particles), an O₉₀ of 1–2 mm works; request dealer information on O₉₀ pore measurement (per ASTM D4751) to make certain alignment with your sediment type, as mismatched pore dimension leads to both waterlogging or sediment loss.

4. Material Compatibility with Fill Sediment & Installation Conditions

Not all Geotextile Tube substances work with each sediment kind or set up environment. Mismatched substances lead to negative performance—even if the fabric is robust or UV-resistant.

Sediment Particle Size Compatibility

The fill sediment’s particle dimension (sand, silt, or clay) dictates the Geotextile Tube material’s texture and pore structure; for coarse sand (particle dimension >0.5 mm), a woven or non-woven geotextile with large pores works (ensures quickly drainage), for excellent silt or clay (<0.05 mm), a non-woven geotextile with smaller pores is wanted (prevents excellent particle loss), and for combined sediment (sand + silt), pick out a hybrid geotextile (combines woven energy with non-woven filtration); the use of the incorrect cloth (e.g., a large-pore cloth for clay) reasons clay loss, decreasing the geosynthetic tubes’ extent and stability.

Installation Site Conditions

Site-specific elements (terrain, climate, and development equipment) affect Geotextile Tube fabric choice; for steep slopes, pick bendy substances (e.g., light-weight non-woven PP) that conform to the terrain besides tearing, for bloodless climates with freezing temperatures, select substances resistant to frost injury (e.g., HDPE, which doesn’t come to be brittle in cold), and for websites with heavy dredging equipment, choose for thick, abrasion-resistant fabric (≥250 g/m²) to stand up to gear contact; ignoring web site prerequisites (e.g., the usage of a inflexible fabric on slopes) leads to set up delays and tube damage.

Conclusion

Choosing the proper Geotextile Tube cloth for land reclamation is a strategic selection that ties at once to task success, cost-efficiency, and environmental compliance. Low-quality or mismatched substances may additionally appear low priced upfront however lead to expensive failures—ruptured geosynthetic tubes, sediment loss, or task delays. By focusing on 4 core factors—environmental degradation resistance (UV, chemical, and biological), mechanical power (tensile, tear, and abrasion), permeability and filtration performance, and compatibility with sediment and web site conditions—you can pick a Geotextile Tube cloth that grants long-term stability. This due diligence ensures your reclamation challenge meets timelines, stays inside budget, and creates durable, usable land that aligns with environmental standards.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province