Maintenance Tips for Prolonging the Life of HDPE Liner Sheets

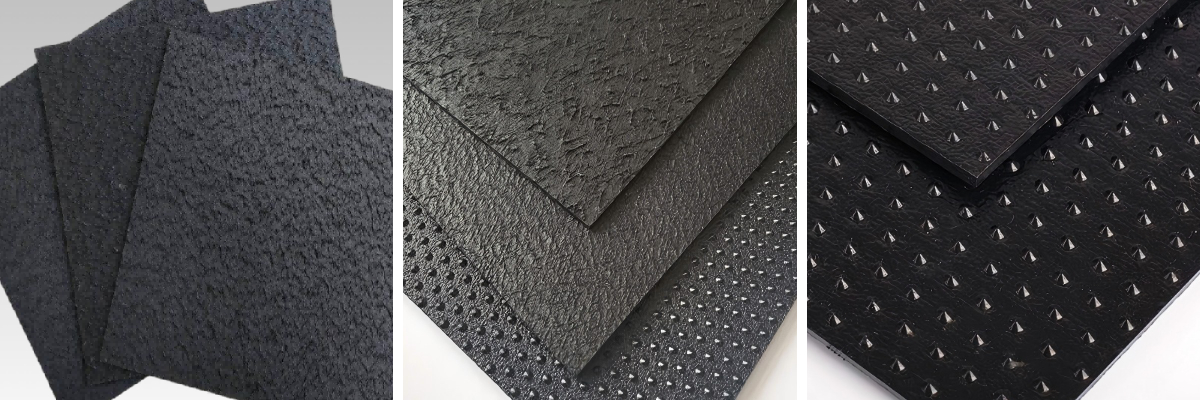

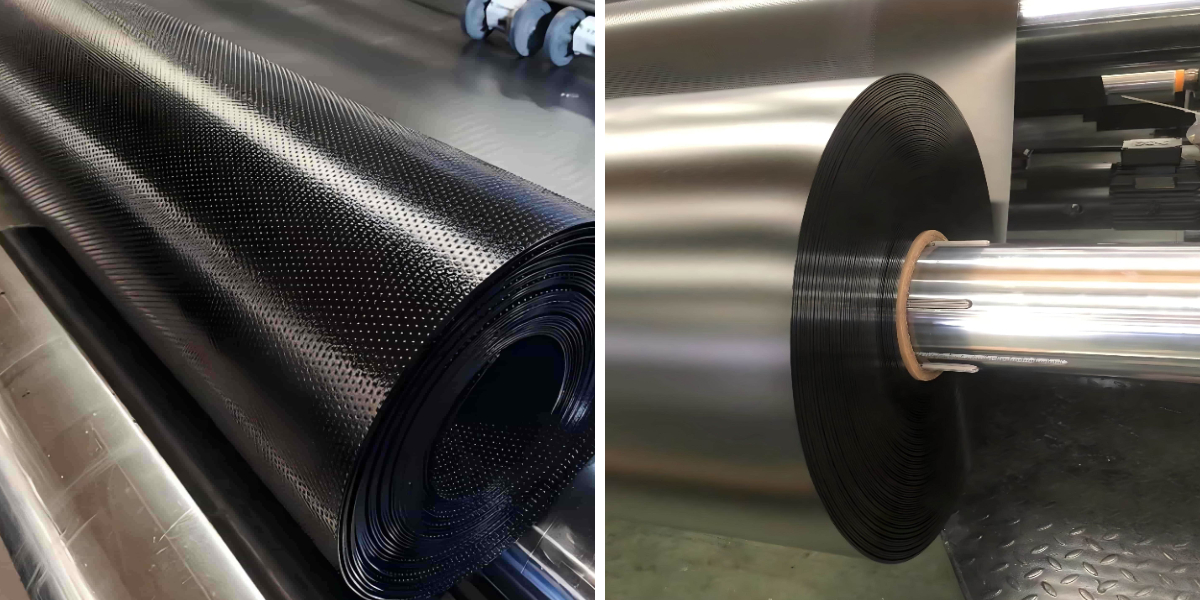

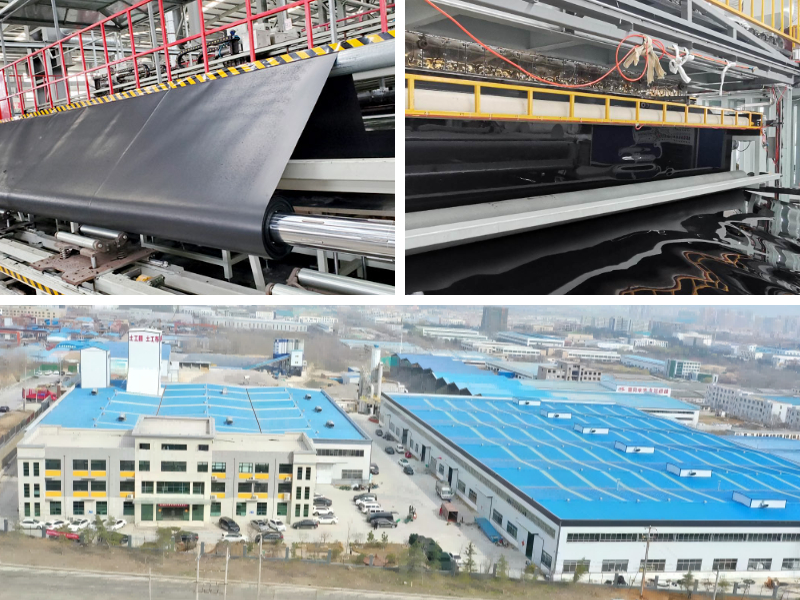

HDPE liner sheets, inclusive of hdpe geomembrane liner, are valued for their sturdiness and resistance to chemicals, making them critical in initiatives like landfills, ponds, and industrial containment. However, even the most sturdy substances require suited preservation to maximize their lifespan—often 20 to 30 years with care. Below are key techniques to guard your investment, with a center of attention on maintaining hdpe liner integrity, addressing problems like wear, and preserving the satisfactory of hdpe liner welding.

1. Regular Inspections: Catching Issues Early

1.1 Scheduled Visual Checks for HDPE Liner

Perform month-to-month visible inspections of the hdpe liner, specially in high-stress areas like corners, seams, and zones with heavy foot or tools traffic. Look for symptoms of damage: punctures from rocks or tools, tears alongside edges, or UV degradation (fading or brittleness). In outside projects, hdpe geomembrane liner is mainly inclined to UV rays, so test for floor cracks that ought to enlarge over time.

For massive installations, use binoculars to check out hard-to-reach areas, and file findings with images to tune changes. Early detection of small issues—like a unfastened seam from compromised hdpe liner welding—prevents expensive repairs later.

1.2 Testing for Leaks in Hdpe Geomembrane Liner

Annual leak checking out is quintessential for hdpe geomembrane liner, mainly in containment structures for chemical substances or wastewater. Use techniques like the spark test, the place a low-voltage probe detects pinholes through developing a spark when it contacts a defect. For large areas, reflect onconsideration on digital leak detection (ELD), which makes use of electrodes to perceive gaps in hdpe liner welding.

Ponds or reservoirs have to additionally bear a water loss test: measure water stages over forty eight hours (accounting for evaporation) to spot hidden leaks. A unexpected drop can also point out a breach in the hdpe liner that desires instantaneous repair.

2. Protecting Against Physical Damage

2.1 Shielding HDPE Liner from Sharp Objects

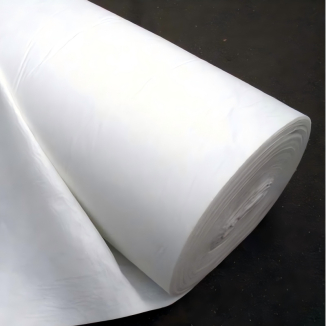

Prevent punctures by way of keeping a protecting layer over the hdpe liner. In landfills, this potential often including a 6-inch layer of soil or geotextile over uncovered liner sections to cushion towards debris. For ponds, deploy a gravel buffer sector round the edges to give up rocks or tree roots from piercing the hdpe geomembrane liner.

When working close to the liner, ban sharp equipment (like shovels with pointed tips) and put in force tools restrictions—heavy equipment need to by no means power without delay on the hdpe liner until on a padded track. Even small punctures can enlarge beneath pressure, so proactive safety is key.

2.2 Managing Traffic and Load Distribution

Limit site visitors on hdpe liner surfaces to detailed paths, the usage of plywood or metal plates to distribute weight when get entry to is necessary. In industrial settings, the place gear motion is frequent, support high-traffic zones with an more layer of hdpe liner or geotextile. This reduces stress on hdpe liner welding, which can weaken if subjected to repeated pressure.

For sloped installations, test that the liner is securely anchored to forestall sliding, which can pressure seams and motive hdpe liner welding to fail. Adjust anchor stakes or weights yearly to account for soil shifts.

3. Addressing Chemical and Environmental Risks

3.1 Monitoring Chemical Exposure for HDPE Liner

Hdpe liner is resistant to most chemicals, however extended publicity to sturdy solvents (like hydrocarbons) or high-concentration acids can motive swelling or degradation. In industrial containment, check saved resources generally to make certain they’re well matched with the hdpe geomembrane liner. If incompatible substances are introduced, line the region with a secondary geotextile barrier to defend the main hdpe liner.

For agricultural ponds, keep away from overusing fertilizers or pesticides—runoff can accumulate in the liner, main to chemical breakdown. Flush the gadget periodically with smooth water to dilute residues.

3.2 Mitigating UV and Weather Damage

UV radiation is a important enemy of uncovered hdpe liner. To defend hdpe geomembrane liner in outside projects, cowl it with soil, mulch, or colour structures. For ponds, keep a layer of water (at least 6 inches) over the liner to block sunlight—this additionally prevents algae growth, which can lure warmth and (accelerate) degradation.

In freeze-thaw zones, make sure perfect drainage beneath the hdpe liner to forestall ice buildup, which can make bigger and crack the material. Insulate edges with foam boards to decrease temperature fluctuations that stress hdpe liner welding.

4. Repairing Damage: Fixing Seams and Tears

4.1 Patching Small Holes in HDPE Liner

For punctures or small tears (less than 6 inches), use a hdpe patch kit. Clean the vicinity round the injury with a solvent (like isopropyl alcohol) to do away with dust and oils, then reduce a patch 3–4 inches large than the hole. Apply a well suited adhesive to each the patch and liner, press firmly, and weigh it down for 24 hours to cure. For hdpe geomembrane liner, heat-weld the patch the usage of a hand welder to make certain a watertight seal.

4.2 Repairing Faulty Hdpe Liner Welding

Seams are the weakest factors in any hdpe liner system, so investigate hdpe liner welding closely. If a seam separates, smooth the location and re-weld it with a wedge welder, following the equal temperature and stress settings used for the duration of installation. For giant gaps, cast off the broken part and exchange it with a new panel, making sure overlapping edges are at least 6 inches for impenetrable re-welding.

Hire licensed technicians for hdpe liner welding repairs, as unsuitable method can lead to routine leaks. Test repaired seams with a vacuum take a look at to verify integrity.

5. Long-Term Maintenance: Extending Liner Life

5.1 Cleaning HDPE Liner Surfaces

Regular cleansing prevents particles buildup, which can lure moisture and promote mildew or bacterial boom (damaging to hdpe liner over time). For ponds, use a soft-bristle brush or strain washer (set to low pressure) to cast off algae—avoid harsh chemical compounds that may want to degrade the hdpe geomembrane liner. In industrial tanks, flush with water month-to-month and scrub partitions gently to put off sediment.

5.2 Documenting Maintenance and Planning Replacements

Keep a specified protection log noting inspection dates, repairs, and fabric tests. This helps predict when the hdpe liner might also want substitute and ensures compliance with enterprise regulations. For example, if hdpe liner welding indicates constant degradation in a particular zone, time table proactive re-welding earlier than screw ups occur.

Plan for partial replacements each 15–20 years, focusing on high-wear areas, to prolong the typical machine life. Investing in pleasant materials—like thick hdpe geomembrane liner—and expert set up minimizes the want for widely wide-spread overhauls.

Conclusion

Maintaining hdpe liner sheets requires a combine of vigilance, proactive protection, and well timed repairs. By conducting ordinary inspections, protecting in opposition to bodily and chemical damage, and addressing problems with hdpe liner welding promptly, you can make certain your hdpe geomembrane liner performs reliably for decades. Whether used in environmental, agricultural, or industrial settings, a well-maintained hdpe liner no longer solely protects towards leaks however additionally preserves the security and effectivity of your whole project.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province