Maintenance and Longevity of PVC Geomembrane

Introduction: Why PVC Geomembrane Longevity Matters

When investing in an tightly closed geomembrane, venture owners and engineers rightfully middle of interest on durability. Among the a vary of synthetic liners available, PVC geomembranes stand out for their flexibility, chemical resistance, and cost-effectiveness. However, their incredible provider life—often exceeding 30 years—is no longer automatic; it hinges on a deliberate, science-based safety strategy. A well-maintained geomembrane liner protects your capital investment, safeguards the environment, and ensures regulatory compliance. This whole data delves into the fundamental practices that prolong the realistic lifespan of your PVC containment system, right away impacting long-term geomembrane liner rate and project success.

Understanding PVC Geomembrane Material Science

Polyvinyl Chloride (PVC) geomembranes are engineered from a base polymer blended with plasticizers, stabilizers, and distinct additives. This factors gives the material its hallmark flexibility, puncture resistance, and potential to accommodate subgrade settlement. Unlike higher rigid materials, a PVC geomembrane liner can stand up to fantastic stress barring cracking. However, its sturdiness is influenced via way of environmental factors like UV exposure, temperature extremes, and the chemical make-up of the contained material. Understanding that the material is lengthy lasting on the other hand no longer indestructible is the first step toward proactive maintenance. Proper care from set up via decommissioning ensures that the preliminary geomembrane liner charge interprets into a lengthy time of reliable service.

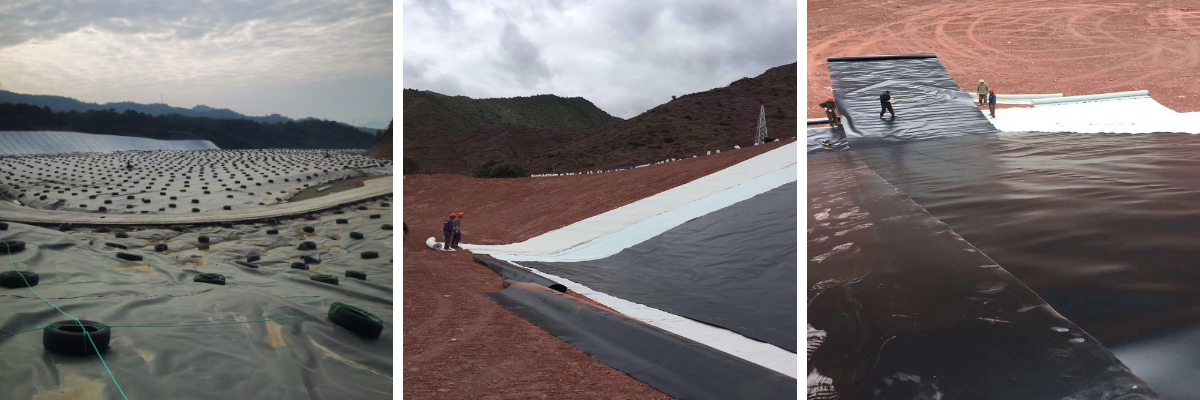

The Critical Role of Professional Installation

Longevity starts offevolved offevolved prolonged previously than maintenance—it starts with flawless installation. A flawlessly formulated PVC impenetrable geomembrane can fail upfront if set up incorrectly. Key set up factors that have an impact on future safety desires and lifespan include:

Subgrade Preparation: The foundation want to be smooth, compacted, and free of sharp rocks or debris. Any irregularities can cause stress points, fundamental to premature wear.

Seaming Methodology: PVC panels are typically seamed the utilization of solvent or hot-air welding. The integrity of every and each seam is paramount; even a small flaw can compromise the complete system.

Proper Anchoring: The liner must be securely located in anchor trenches to face up to wind uplift and movement.

Investing in certified, professional installers would possibly additionally add to the upfront geomembrane liner price on the other hand prevents exponentially higher fix or replacement expenses later. A efficaciously hooked up PVC geomembrane liner affords a invulnerable baseline for all subsequent safety activities.

Proactive Inspection: The First Line of Defense

Routine inspection is the most fine system in your renovation arsenal. It transforms renovation from a reactive to a predictive practice. We propose a tiered inspection approach:

Daily/Weekly Visual Checks: For full of life web sites like landfills or ponds, brief seen scans for obvious issues—pooling water, uncovered liner, or debris—are essential.

Scheduled Formal Inspections: Conduct comprehensive, hands-on inspections quarterly or bi-annually. Walk the complete area, checking for signs of wear, seam integrity, and cowl material stability.

Detailed Diagnostic Surveys: Employ finest utilized sciences like electrical leak neighborhood (ELL) surveys every 2-5 years. This non-destructive test can pinpoint holes as small as a pinhole, a methods previous the performance of the human eye.

Regularly scheduled inspections help manage the lifetime geomembrane liner fee thru figuring out minor issues until now than they give a boost to into primary failures.

Essential Cleaning and Debris Management

Accumulated particles is more than an eyesore; it’s a threat. Organic matter, standing water, and rocks can create localized stress, promote natural growth, or conceal damage.

Remove Vegetation: Roots from plant existence or bushes can penetrate the impenetrable geomembrane. Keep a vegetation-free buffer vicinity and manually do away with any extend in the past than roots establish.

Clear Solids and Sediment: For uncovered liners, use soft-bristled brooms or low-pressure water washing. Avoid abrasive gear or high-pressure jets that ought to scratch or harm the surface.

Manage Water Ponds: While a PVC geomembrane liner is designed to consist of liquids, prolonged, unsupported standing water on the ground can pace up plasticizer migration in that spot. Ensure ideal drainage off the liner surface.

A convenient geomembrane is much less problematic to inspect and is challenge to a great deal much less environmental stress, at as soon as contributing to its longevity.

Effective Repair Protocols for PVC Geomembranes

Despite first-rate efforts, damage can occur. The tempo and exceptional of the repair are critical. For a PVC geomembrane, the fix approach generally involves:

Identification and Marking: Clearly mark all damaged areas found at some factor of inspection.

Cleaning and Preparation: The damaged area and a surrounding margin ought to be meticulously cleaned and dried.

Patching: A patch of the same PVC material, with rounded corners, is placed over the damage. The patch want to be giant than the defect by way of a unique minimal overlap.

Seaming: The patch is welded to the mum or dad geomembrane liner the use of the fantastic thermal or chemical method, matching the proper seam strength.

Testing: Every repair seam have to be non-destructively examined (e.g., air stress take a look at for dual-track seams) to affirm integrity.

Maintaining a fix package deal on-site for minor troubles can give up small punctures from expanding, defending your funding and controlling long-term geomembrane liner cost.

Managing Environmental and UV Exposure

UV radiation from daytime is a predominant factor in the getting older of uncovered geomembranes. While super PVC formulations embody UV stabilizers, protection extends their life significantly.

Use Protective Covering: The most first-rate method is defending the liner with soil, water, or a geotextile. This handy step shields the fabric from UV rays and temperature swings.

Apply Coatings: For uncovered applications, specialised reflective or anti-UV coatings can be utilized to limit degradation.

Consider Placement: In the diagram phase, suppose about strategies to restrict direct, continuous photo voltaic publicity on quintessential areas.

Managing publicity is a low-effort, high-impact technique that preserves the mechanical homes of your PVC impervious geomembrane for decades.

Detailed Record-Keeping for Lifecycle Management

Comprehensive documentation is the backbone of strategic maintenance. A special "as-built" document and ongoing renovation log want to include:

Installation dates, panel layouts, and seam maps

Material information sheets and producer warranties

Dates and findings of every and each inspection

Details of every repair: location, cause, method, and technician

Results of all integrity tests

This record serves greater than one purposes: it tracks the system's health, informs future safety decisions, proves due diligence to regulators, and presents a clear files if warranty claims are necessary. It is the definitive narrative of your geomembrane liner price versus rate story.

Cost-Benefit Analysis of a Proactive Maintenance Program

Viewing renovation as an optionally on hand charge is a luxurious misconception. A proactive software program is a capital renovation strategy. The economics are clear:

Preventative Cost: Regular inspections and minor repairs represent a small, predictable annual expense.

Failure Cost: A most vital liner failure can lead to catastrophic environmental contamination, large regulatory fines, highly-priced emergency repairs, complete replacement, and devastating project downtime.

The preliminary geomembrane liner cost is a consistent investment. The variable is how heaps greater money you spend over its life. Proactive upkeep minimizes this variable, making certain the lowest workable entire rate of ownership. A well-cared-for PVC geomembrane liner delays the big capital outlay of choice indefinitely.

Conclusion: Your Long-Term Containment Strategy

A PVC geomembrane is a durable, high-performance engineering fabric designed for the prolonged haul. Its inherent homes make it an terrific desire for creating a reliable invulnerable geomembrane barrier. However, its conceivable 30+ 12 months company existence is completely feasible by using a committed, educated renovation regimen. From meticulous set up and occasions cleaning to top-quality leak detection and great repairs, every movement you take without delay contributes to the system's integrity.

By implementing the practices outlined in this guide, you pass previous effortless containment. You undertake a lifecycle administration philosophy that maximizes return on investment, ensures environmental stewardship, and turns the upfront geomembrane liner charge into a story of long-term value, resilience, and undertaking success. Start your strategic renovation graph these days to impenetrable your asset's typical overall performance for tomorrow.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province