Installation guide for geocell for slope protection

Introduction

Slope protection is crucial in various civil engineering projects, as it relates to the stability of the project and the safety of the surrounding environment. Geogrid, as an efficient geosynthetic material, is widely used in the field of slope protection due to its unique structure and excellent performance. This article will comprehensively introduce how to install geocell for slope protection(https://www.cggeosynthetics.com/hdpe-geocell/geocell-driveway.html), providing detailed guidance for related engineering practices.

Advantages of using geogrids for slope protection

1.Enhance slope stability

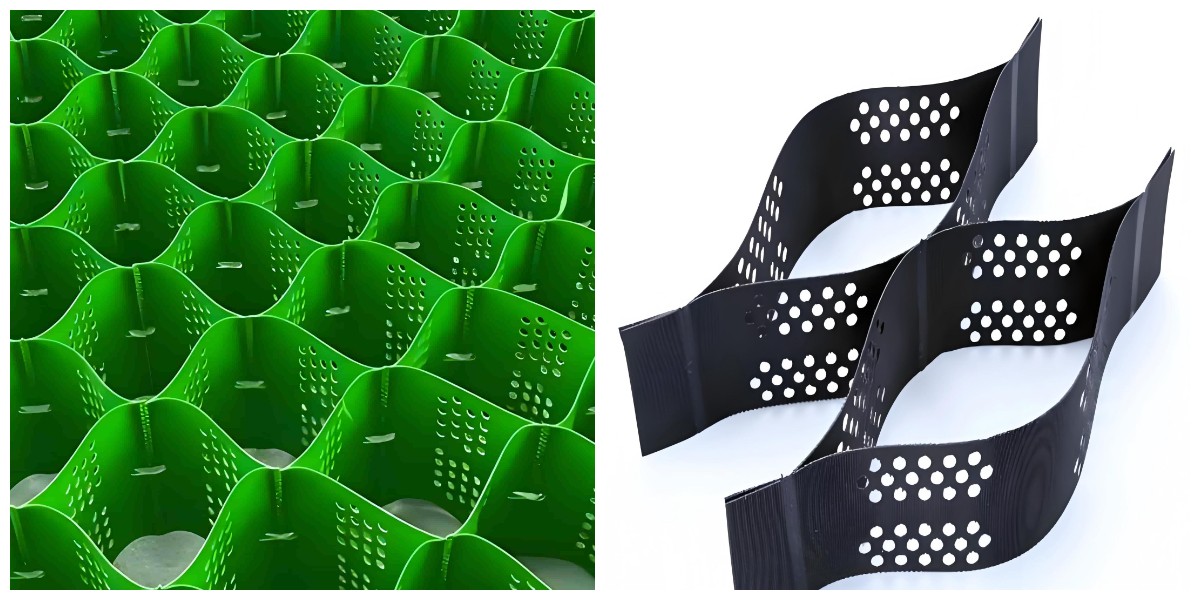

The three-dimensional mesh structure of the geogrid can effectively constrain the filling material and prevent soil sliding. When the slope is subjected to external forces such as gravity, rainwater erosion, or earthquakes, the overall structure formed by the grid and filling materials can disperse stress, enhance the anti sliding ability of the slope, and significantly improve stability. For example, in mountainous highway slopes, they are often threatened by landslides, and the use of geocell for slope protection(https://www.cggeosynthetics.com/hdpe-geocell/geocell-driveway.html )can effectively resist landslide risks.

2.Prevent soil erosion

The honeycomb structure of the grid can slow down the velocity of water flow on the slope and reduce the scouring force of water flow on the soil. The filling material is not easily washed away in the compartment, which can effectively maintain the soil and reduce soil erosion. This advantage is particularly crucial in slope protection around rivers, lakes, and other water bodies, which helps to protect the ecological environment of water bodies.

3.Promote vegetation growth

Geogrids create favorable conditions for vegetation growth. The filling soil in the greenhouse can fix plant roots, provide nutrients and water, and promote rapid vegetation growth. The vegetation root system can further reinforce the soil, forming an ecological slope protection system that synergizes vegetation and geogrids for protection. It has significant application effects in urban landscape slopes, highway greening slopes, and other projects.

4.Convenient construction and high cost-effectiveness

Geogrid cells are lightweight and easy to transport. During construction, they only need to be unfolded, fixed, and filled with materials, without the need for complex equipment and technology, which can greatly shorten the construction period. At the same time, it can use local materials, reduce material transportation and procurement costs, and lower engineering costs, which highlights its advantages in various budget limited slope protection projects.

Preparation work before installation

1.Slope survey and design

Before installing the geogrid, a detailed survey of the slope is required. Measure slope gradient, height, length and other parameters, evaluate geological conditions, including soil type, stability, groundwater level, etc. Based on the survey results, combined with engineering requirements and relevant specifications, carry out slope protection design, determine the model, specifications, laying range and method of the geocell for slope protection(https://www.cggeosynthetics.com/hdpe-geocell/geocell-driveway.html), as well as the type of filling material.

2.Preparation of materials and tools

According to the design requirements, purchase qualified geogrids and inspect their appearance for damage, holes, and performance indicators such as tensile strength, welding strength, and aging resistance to ensure compliance with standards. Prepare filling materials such as sand, gravel, soil, etc., ensuring that their grading, mud content, and other indicators meet the design requirements, without impurities or large particles. At the same time, prepare the necessary tools for installation, such as U-nails, wire, connectors, loaders, rollers, measuring instruments, etc., and check the performance and safety of the tools.

3.Site cleaning and leveling

Remove weeds, trees, garbage, loose stones and other debris from the slope to prevent any impact on the laying of the geogrid and the stability of the slope. According to the design slope, the slope can be leveled manually or mechanically, using equipment such as bulldozers and excavators. The leveled slope should meet the design requirements, with a smooth surface and no obvious unevenness.

Installation process of geocell

1.Unfolding and laying of geogrids

Unfold the geogrid on the leveled slope according to the design direction and position. When unfolding, be careful to avoid twisting, folding, or damaging the compartments, ensuring that they are flat and straight. Adjacent geogrids shall be overlapped according to the design requirements, generally 15-20cm, and firmly connected with connectors (such as iron wire, special connectors) to ensure connection strength and integrity.

2.Fixed geogrid chamber

To prevent displacement of the geogrid during construction and use, it is necessary to fix it. Set fixed points at a certain distance around and inside the grid, and use U-shaped nails or anchoring devices to fix the grid to the slope. The spacing between fixed points is determined by the size of the grid, the properties of the filling material, and the slope conditions, generally ranging from 1-2 meters. At the top and bottom of the slope, the grid should be buried to a certain depth, such as 0.5-1 meter at the top and 0.3-0.5 meters at the bottom, and backfilled and compacted with soil to enhance stability.

3.Connection with slope drainage system

Slope drainage is crucial for the effectiveness of protection. The installation of geocell for slope protection(https://www.cggeosynthetics.com/hdpe-geocell/geocell-driveway.html) should be closely coordinated with the drainage system to ensure smooth drainage. When setting up drainage holes and ditches on the slope, be careful not to damage the geocell. The connection between the geogrid and the drainage facilities shall be sealed with geotextile or other materials to prevent the loss of filling materials and ensure the normal drainage function.

4.Construction of filling materials

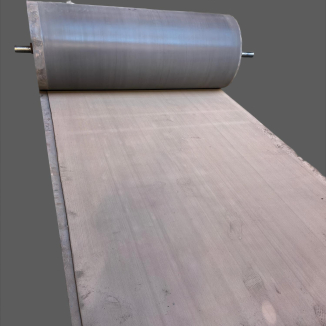

Select filling materials that meet the requirements, transport them to the construction site by dump truck, and avoid damaging the geocell during unloading. Fill the filling material evenly into the compartment, which can be manually assisted with mechanical operation to ensure full filling without voids or loose areas. After filling one layer, compact it with a roller. First, static pressure is applied using a 25t vibratory roller for 2-3 times to achieve initial compaction of the material; Further vibration and compaction, use a 50t vibratory roller to vibrate and compact 4-5 times to improve the density. The compaction degree should meet the design requirements, generally not less than 90%. Lay geogrids and filling materials in layers according to the design thickness, with the same construction process for each layer. After the lower layer is accepted as qualified, the upper layer can be constructed.

5.Vegetation planting (if necessary)

If vegetation protection is adopted in the design, vegetation planting shall be carried out after the completion of filling material construction. Select suitable plant species based on local climate and soil conditions, such as herbaceous plants, shrubs, etc. Evenly sow seeds or transplant seedlings in the greenhouse, and water and maintain them promptly after planting to promote vegetation growth. Fertilizers, water retaining agents, etc. can be added to the greenhouse to provide nutrients and water for plant growth.

Maintenance and inspection after installation

1.Regular inspection

After the installation of the geogrid, regular inspections should be conducted on the slope to check for any damage, displacement, loose connections, loss or collapse of filling materials, and good vegetation growth. The first inspection shall be carried out 1-2 weeks after installation, and then monthly or quarterly, and timely inspection shall be carried out under special circumstances (such as rainstorm and earthquake).

2.Maintenance measures

If the geogrid is found to be damaged, repair or replace the damaged parts in a timely manner; Loose connection parts, re reinforce; Loss or collapse of filling materials, replenishment of materials and compaction; Poor vegetation growth, strengthen maintenance work such as watering, fertilization, and pest control. Regularly clean up debris and accumulated water on the slope, and keep the drainage system unobstructed.

Case analysis

Case 1: Slope Protection Project for a Mountain Highway

(1)Project background: The mountainous road has a steep slope and complex geological conditions, which are easily affected by rainwater erosion and landslides, posing a threat to driving safety.

(2)Solution: Use geocell for slope protection(https://www.cggeosynthetics.com/hdpe-geocell/geocell-driveway.html). Firstly, conduct a survey and design of the slope, and select a suitable specification of geocell. Clean and level the slope during construction, lay and fix the geocell as required, fill with crushed stone soil and compact it. Plant herbaceous plants and shrubs in the greenhouse.

Implementation effect: After years of use, the slope is stable and there have been no accidents such as landslides or collapses. Soil erosion has been significantly reduced, vegetation has grown well, and an ecological protection system has been formed, ensuring the safe operation of the highway and improving the surrounding environmental landscape.

Case 2: A river slope protection project

(1)Project background: The river slope is severely eroded by water flow, causing soil loss and affecting the safety of the river and the surrounding ecological environment.

(2)Solution: Adopt a geocell for slope protection(https://www.cggeosynthetics.com/hdpe-geocell/geocell-driveway.html) scheme. After measuring and designing the river slope, install a geogrid chamber, fill it with sand and gravel, and effectively connect it with the drainage system.

Implementation effect: The anti - erosion ability of the slope is enhanced, the erosion of the slope by water flow is significantly reduced, the riverbank soil is protected, the habitat for aquatic organisms is provided, and the ecological environment of the river channel is improved.

Conclusion

Geogrid chambers are used for slope protection and have significant advantages. The installation process requires preparation work, strict adherence to procedures, and strengthened maintenance and inspection after installation. Through practical cases, it can be seen that the correct installation and use of geocell for slope protection (https://www.cggeosynthetics.com/hdpe-geocell/geocell-driveway.html)can effectively improve slope stability, prevent soil erosion, promote vegetation growth, and achieve a win-win situation between engineering and ecological benefits. In future slope protection engineering, geogrids will play a more important role, and with the development of technology and the accumulation of application experience, their application prospects will be broader.

CONTACT US

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province