Installation Guide: Properly Laying Geotextile Cloth for Road Construction

Geotextile material has turn out to be a cornerstone in cutting-edge avenue construction, providing stronger stability, drainage, and erosion control. Whether you’re working on a small rural avenue or a giant dual carriageway project, laying geotextile material efficaciously is necessary for long-term performance. This information will stroll you thru the step-by-step system of putting in geotextile material in avenue construction, with a focal point on realistic hints and key merchandise like geotextile avenue material for sale, non woven geo fabric, and geofabrics on hand at Bunnings.

Why Geotextile Cloth Matters in Road Construction

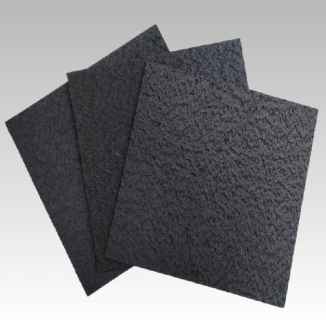

Before diving into the set up process, it’s critical to recognize why geotextile fabric is a game-changer for roads. These artificial fabrics—including famous choices like non woven geo fabric—act as a barrier between special soil layers, stopping mixing of subgrade and mixture materials. This separation reduces soil erosion, enhances load distribution, and improves drainage, all of which prolong the road’s lifespan.

For avenue projects, geotextile avenue cloth for sale is designed to face up to heavy loads, withstand punctures, and tolerate harsh climate conditions. Whether sourced from suppliers or outlets like Bunnings, geofabrics right here are examined to meet enterprise standards, making sure reliability in high-traffic areas. Non woven geo fabric, in particular, is liked for its permeability and strength, making it best for drainage-focused street sections.

Pre-Installation Preparation: Key Steps Before Laying

1. Site Assessment and Material Selection

Start with the aid of evaluating the street site. Check soil type, slope, and drainage patterns to decide the proper geotextile fabric. For most avenue projects, non woven geo material is a pinnacle preference due to its versatility. If you’re unsure, go to Bunnings to discover their vary of geofabrics—their professionals can assist healthy the product to your project’s needs.

When sourcing geotextile street material for sale, prioritize merchandise with excessive tensile energy and UV resistance. These aspects make certain the material can deal with heavy equipment all through development and withstand degradation from daylight over time.

2. Clearing and Grading the Subgrade

The subgrade (the herbal soil layer underneath the road) ought to be top organized earlier than laying geotextile cloth. Remove all debris, rocks, and vegetation to create a smooth, even surface. Use grading gear to degree the area, making sure a slope of 1-2% for ample drainage.

Compact the subgrade with a curler to stop future settlement. Any unevenness or free soil can motive the geotextile cloth to tear or shift, so take time to get this step right.

Step-by-Step Installation of Geotextile Cloth

1. Unrolling and Positioning the Fabric

Once the subgrade is ready, it’s time to lay the geotextile cloth. Start from one quit of the avenue and unroll the material alongside the size of the building area. For massive projects, use geotextile street material for sale in bulk rolls to reduce seams, which are viable susceptible points.

Overlap adjoining cloth rolls by means of at least 30 cm (12 inches) to make sure full coverage. This overlap prevents soil from seeping thru gaps. For steep slopes or high-stress areas, amplify the overlap to 60 cm (24 inches) for delivered security.

2. Securing the Geotextile Cloth

After positioning, tightly closed the material to the subgrade to stop motion throughout combination placement. Use stakes or anchor pins made of metal or plastic, spacing them 1-2 meters aside alongside the edges and seams. For non woven geo fabric, keep away from over-tightening the stakes, as this can stretch or harm the material.

If you’re working in windy conditions, invulnerable the cloth in sections to hold it from blowing away. This is the place geofabrics from Bunnings shine—their long lasting selections are much less susceptible to tearing in the course of installation.

3. Avoiding Common Installation Mistakes

Punctures: Keep sharp equipment and heavy equipment off the laid fabric. Even non woven geo material can tear if uncovered to sharp rocks or equipment.

Seam Strength: Ensure overlaps are appropriate aligned and secured. Weak seams are a main reason of cloth failure.

UV Exposure: Don’t depart geotextile material uncovered for prolonged periods. If delays occur, cowl the material with a layer of combination to guard it from sunlight.

Post-Installation: Adding Aggregate and Compaction

Once the geotextile material is securely laid, it’s time to add the combination base. Spread the combination evenly over the fabric, beginning from the middle and working outward. The thickness of the combination layer relies upon on the road’s design—typically 10-30 cm for residential roads and up to 50 cm for highways.

After spreading, compact the combination with a roller. This step bonds the combination to the geotextile fabric, developing a steady base. For quality results, use a vibratory curler to make certain suitable compaction besides negative the underlying fabric.

Remember, the aggregate of geotextile avenue cloth for sale and well-compacted combination is what offers the avenue its strength. Skipping compaction can lead to uneven settling and potholes down the line.

Maintenance Tips for Long-Lasting Performance

To maximize the lifespan of your geotextile-reinforced road, observe these preservation practices:

Inspect the street often for signs and symptoms of material exposure, such as tears or uplifted edges. Repair small troubles directly with patches of non woven geo fabric.

Ensure drainage structures (like culverts) are clear to forestall water buildup, which can weaken the geotextile material over time.

For substitute needs, inventory up on geofabrics from Bunnings or depended on suppliers. Having spare rolls on hand minimizes downtime at some point of repairs.

Where to Source Quality Geotextile Products

Finding dependable geotextile substances is key to a profitable installation. Geotextile street cloth for sale is reachable from specialised building suppliers, however for convenience, outlets like Bunnings provide a vary of geofabrics appropriate for small to medium projects. Their non woven geo material picks are low-priced and convenient to transport, making them a favourite amongst neighborhood contractors.

When purchasing, take a look at for certifications like ISO or ASTM to make certain the material meets enterprise standards. Investing in first-class substances now saves time and cash on repairs later.

Conclusion

Laying geotextile fabric efficaciously is a necessary step in constructing durable, long-lasting roads. By following this guide—from website guidance to fabric resolution and applicable installation—you can make certain the material performs as intended. Whether you select non woven geo fabric, supply geotextile street cloth for sale in bulk, or pick out up geofabrics from Bunnings, interest to element at some stage in set up is the key to success.

With the proper strategies and materials, your geotextile-reinforced avenue will stand up to heavy traffic, harsh weather, and the check of time.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province