How to Test HDPE Geomembrane Quality: A Buyer’s Checklist for Durability & Impermeability

When it comes to civil engineering, environmental protection, or waste administration projects, the first-rate of HDPE Geomembrane at once determines the project’s longevity, safety, and cost-effectiveness. As a buyer, investing in low-quality Geomembrane can lead to catastrophic leaks, structural failures, and luxurious rework. To assist you keep away from these risks, this information outlines a complete guidelines to take a look at HDPE Membrane quality, focusing on the two most indispensable overall performance indicators: sturdiness and impermeability. By following these steps, you can make sure you’re buying a product that meets enterprise requirements and your project’s precise needs.

1. Verify Basic Physical Properties: The Foundation of Quality HDPE Geomembrane

The bodily residences of HDPE Geomembrane are the spine of its durability. Skipping these simple assessments can depart you with a product that can’t stand up to even activities use. Here are the key metrics to inspect:

1.1 Thickness Uniformity

Thickness is a non-negotiable aspect for HDPE Membrane performance, as uniform thickness ensures constant load-bearing capability and impermeability throughout the complete sheet; to take a look at this, use a calibrated digital thickness gauge (with a size accuracy of ±0.01mm) to take 10-15 random readings on a single sheet, focusing on edges and corners which are susceptible to thinning at some point of production, then examine the readings to the manufacturer’s referred to thickness (e.g., 1.0mm, 1.5mm, 2.0mm) – the most deviation have to now not exceed ±5% (any greater suggests bad manufacturing control) due to the fact skinny spots are susceptible factors that can tear below anxiety or fail to block moisture, whilst overly thick areas waste cloth and expand set up difficulty.

1.2 Tensile Strength and Elongation at Break

Tensile strength, which measures how an awful lot pressure the Geomembrane can face up to earlier than breaking, and elongation at break, which shows its flexibility, are each integral for sturdiness for the duration of set up and long-term use; to take a look at these, reduce general dog-bone fashioned samples from the HDPE Geomembrane (following ASTM D638 standards) and use a widespread trying out laptop to observe gradual anxiety till the pattern breaks, with enterprise requirements requiring a minimal tensile electricity of 18 MPa for 1.0mm thick HDPE Membrane and 25 MPa for 2.0mm thick sheets, plus an elongation at spoil of at least 500% (this flexibility approves the membrane to adapt to floor agreement except cracking), whilst low tensile electricity (below 15 MPa) or elongation (under 400%) are crimson flags indicating inferior uncooked substances or incorrect extrusion at some point of manufacturing.

2. Test Impermeability: The Core Function of HDPE Geomembrane

Impermeability is the foremost purpose for selecting HDPE Membrane—whether for landfill liners, pond liners, or wastewater remedy facilities. Even tiny pores can lead to environmental infection or mission failure. Use these assessments to validate impermeability:

2.1 Water Tightness Test (Laboratory)

Laboratory water tightness tests, especially the hydrostatic strain test, grant quantitative records on the membrane’s barrier performance: seal a round pattern of HDPE Geomembrane in a stress chamber, observe gradual water stress (starting from 0.1 MPa, growing with the aid of 0.05 MPa each and every 30 minutes), and display for water seepage on the contrary side, with certified HDPE Membrane wanting to face up to 0.3 MPa for 24 hours except leakage (the minimal trendy for landfill and industrial applications), whilst for high-risk tasks like hazardous waste landfills, trying out at 1/2 MPa for forty eight hours is encouraged to make sure greater protection.

2.2 Vacuum Test (On-Site)

On-site vacuum exams are quick, non-destructive strategies to take a look at for defects like pinholes or cracks brought for the duration of transportation or installation: follow a 20-30cm diameter vacuum ring to the hooked up Geomembrane, seal the edges with putty, join a vacuum gauge, create a 0.08 MPa vacuum and keep it for five minutes – no stress drop potential the place is impermeable, whilst a drop shows a leak that wishes marking and instant restore – and this check need to be carried out each 100㎡ of hooked up membrane, with greater assessments round seams and overlaps (the most frequent leak points).

3. Evaluate Environmental Resistance: Ensure Long-Term Durability

HDPE Geomembrane operates in harsh environments—exposed to sunlight, chemicals, and bodily abrasion. Testing its resistance to these elements ensures it lasts 20-30 years (the anticipated lifespan of fantastic products). Focus on three key areas:

3.1 UV Resistance Test

Prolonged daylight publicity degrades low-quality HDPE Membrane, inflicting brittleness and cracking, so to take a look at UV resistance, use a xenon arc weatherometer to simulate 5000 hours of outside UV publicity (equivalent to 5-7 years of real-world use), then recheck tensile electricity and elongation – a certified membrane ought to hold at least 80% of its authentic tensile electricity (any much less capability inadequate UV stabilizers) – and it’s really useful to ask producers for a UV stabilizer certificates because great merchandise use 2-3% carbon black or specialised UV inhibitors at some point of production.

3.2 Chemical Resistance Test

For initiatives involving wastewater, chemicals, or agricultural runoff, Geomembrane have to withstand corrosion, so to take a look at chemical resistance, immerse HDPE Geomembrane samples in frequent chemical substances (e.g., 10% sulfuric acid, 20% sodium hydroxide, or nearby wastewater) for 30 days at 25℃, then measure weight trade (which have to be ≤±2%) and tensile electricity retention (which must be ≥90%), and for intense chemical environments like industrial waste ponds, it’s indispensable to request custom-formulated HDPE Membrane with more advantageous chemical resistance.

3.3 Puncture Resistance Test

Roots, rocks, or building gear can puncture HDPE Membrane, so puncture resistance is integral for durability, and following ASTM D4833 standards, this take a look at entails the usage of a 12.7mm diameter metal probe to penetrate the membrane at a steady velocity (10mm/min) till puncture takes place – a certified 1.5mm thick HDPE Geomembrane must have a puncture resistance of at least 300N, with a goal of 400N or higher for landfill liners.

4. Inspect Seam Quality: The Weak Link of Geomembrane Installation

Even the highest-quality HDPE Geomembrane will fail if seams are poorly bonded. Seams account for 80% of on-site leaks, so rigorous trying out is mandatory:

4.1 Peel Strength Test

Peel energy measures how properly two sheets of HDPE Membrane are bonded at the seam, and to take a look at it, reduce 50mm large samples from the seam (perpendicular to the seam line) and use a conventional trying out laptop to pull the two sheets aside at a 90° attitude – the minimal peel electricity for thermal-welded seams (the most frequent technique for HDPE Geomembrane) is three N/mm, and if the seam peels aside without difficulty or the electricity is beneath standard, it shows fallacious weld temperature or speed.

4.2 Air Pressure Test (On-Site Seam Inspection)

The on-site air stress check is quick and superb for large-scale installations to test for voids in welded seams: seal each ends of a 1m area of the welded seam with plugs, inject air the usage of a stress gauge till accomplishing 0.02 MPa, then maintain the strain for five minutes – no stress drop shows a stable seam, whilst a strain drop ability there’s a gap in the weld that requires finding with cleaning soap water and re-welding.

Final Buyer’s Checklist: Summarizing Key Tests

Before buying HDPE Geomembrane, affirm the following exams have been performed (and ask for third-party certification if possible): make sure bodily houses meet requirements with thickness uniformity (±5% deviation), tensile power (≥18 MPa), and elongation at destroy (≥500%); verify impermeability via hydrostatic stress check (0.3 MPa for 24h, no leakage) and on-site vacuum take a look at (no stress drop); test environmental resistance such as UV resistance (80% tensile electricity retention after 5000h UV exposure), chemical resistance (≤±2% weight change), and puncture resistance (≥300N); and verify seam great with peel energy (≥3.0 N/mm) and air stress check (no stress drop).

Conclusion: Invest in Quality HDPE Geomembrane to Avoid Costly Failures

Testing HDPE Geomembrane fine isn’t simply a formality—it’s a essential step to defend your project, budget, and reputation. By focusing on bodily properties, impermeability, environmental resistance, and seam quality, you can pick out a Geomembrane that provides long-term durability. Remember: The price of investing in first-class trying out is a long way decrease than the price of repairing leaks or changing failed HDPE Membrane later. Choose a official dealer who gives obvious take a look at reports, and don’t hesitate to request on-site inspections at some stage in installation.

Contact Us

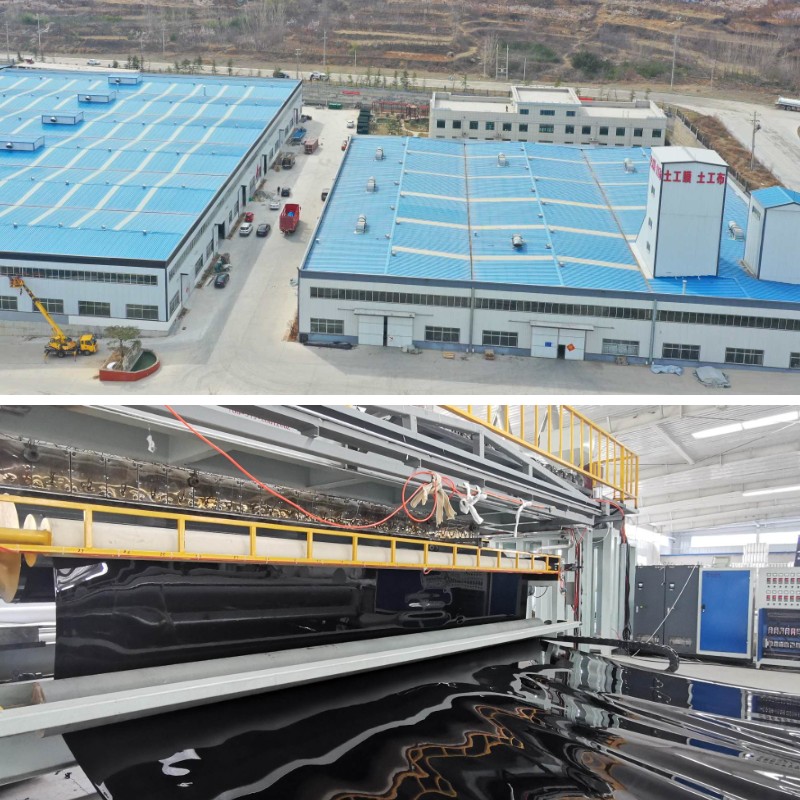

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province