Preventing Concrete Freezing: Can a Cement Blanket Save Your Project?

Pouring concrete in bloodless climate is a race in opposition to time and temperature. When the mercury drops, the water inside the concrete combine is at threat of freezing, main to a catastrophic loss of power and durability. For challenge managers and DIY lovers alike, this situation is a most important supply of stress and workable fee overruns. But what if there used to be a reliable, environment friendly way to shield your pour? Enter the cement blanket, a cutting-edge innovation designed to handle this specific challenge. This article explores how this specialised concrete cloth constructing answer can be the distinction between a successful, long lasting shape and a costly, failed project.

The Hidden Danger: Why Frozen Concrete Fails

Before perception the solution, it is vital to hold close the problem. Concrete does not "dry" via evaporation; it "cures" via a chemical response known as hydration. Water is a key ingredient in this process, reacting with cement particles to shape the strong, crystalline bonds that provide concrete its strength.

When freshly poured concrete freezes, the water inside it turns to ice. Since ice expands with the aid of about 9% in volume, it creates giant interior pressure. This enlargement disrupts the formation of the cement paste's bonding structure, completely negative the concrete matrix. The end result is a last product that can have up to 50% much less energy and is notably extra porous and inclined to scaling, cracking, and weathering. This injury is frequently irreversible, necessitating steeply-priced demolition and re-pours. Preventing this consequence is now not simply a first-class practice; it is a imperative requirement for structural integrity.

What is a Cement Blanket? A Modern Winter Concreting Solution

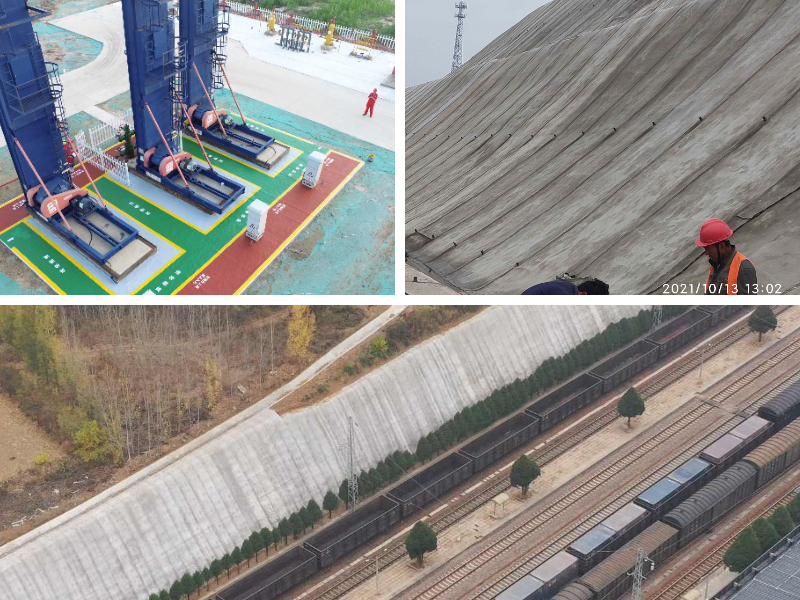

A cement blanket is an advanced, all-in-one curing and safety system. Unlike normal techniques that contain layering straw, tarps, and unreliable warmness sources, this answer is engineered for effectivity and performance. At its core, it is a durable, chemical-resistant concrete material layer that is crammed with a proprietary cementitious powder.

When activated by way of water, this blanket will become a self-contained, insulated curing environment. The outer layer is a tough, weatherproof, and frequently chemical-resistant concrete fabric that protects in opposition to the factors like rain, wind, and snow. The internal core absorbs water and initiates an exothermic (heat-releasing) chemical reaction. This procedure generates a consistent, low-level heat, successfully turning the blanket into a heated shell that wraps snugly round your concrete pour. This revolutionary strategy to concrete cloth constructing ensures a managed surroundings for ideal curing, regardless of the outdoor temperature.

Key Advantages of Using a Concrete Blanket for Cold Weather Pours

Why need to you select a cement blanket over older, extra ordinary methods? The advantages are good sized and at once influence your project's timeline, budget, and ultimate quality.

1. Consistent and Reliable Heat Generation

The predominant motive of a cement blanket is to supply uniform heat. The exothermic response is predictable and self-regulating, retaining a temperature properly above the indispensable freezing point. This eliminates the warm and bloodless spots frequent with transportable heaters or warmness lamps, making sure each and every phase of your slab or shape treatments evenly.

2. Ease of Installation and Significant Time Savings

Time is cash on any job site. Installing a regular insulated enclosure is a labor-intensive process. In contrast, a concrete cloth constructing answer like this is as easy as unrolling the blanket over the freshly poured concrete, slicing it to healthy complicated shapes if necessary, and then activating it with water. This can retailer hours, if no longer days, of labor, permitting your crew to pass on to different crucial tasks.

3. Superior Protection and Enhanced Curing

Beyond simply heat, a cement blanket gives a entire defensive barrier. The robust, chemical-resistant concrete fabric exterior shields the sparkling concrete from bodily damage, moisture loss, and even many frequent job-site chemicals. By trapping moisture, it ensures the hydration method continues uninterrupted, main to a stronger, harder, and greater long lasting ultimate surface. This twin motion of heating and moisture retention is what units this technique apart.

4. Reusability and Cost-Effectiveness

While the preliminary price can also be greater than disposable substances like straw and plastic, many fantastic cement blanket merchandise are reusable. With suited care and storage, they can be used on more than one projects, offering splendid long-term fee and decreasing cloth waste. This makes them an economically clever desire for contractors and accepted DIYers.

Practical Application: How to Use a Cement Blanket on Your Job Site

Implementing a cement blanket is a simple process, however interest to element is key for success.

Surface Preparation: Pour your concrete as usual, following all trendy strategies for bloodless climate concreting, such as making sure the subgrade is now not frozen.

Place the Blanket: Once the concrete has been completed and is equipped for curing, unroll the cement blanket without delay onto the surface. Drape it over walls, columns, or complicated forms, reducing it with a utility knife for a ideal fit. Ensure the seams are overlapped to forestall warmth loss.

Activate with Water: Thoroughly saturate the blanket with water, generally the use of a backyard hose. The activation triggers the heat-producing chemical response inside the concrete material constructing material.

Monitor and Maintain: While the blanket works autonomously, it is top exercise to periodically take a look at the concrete temperature with a thermometer to make sure it stays above the required minimal (typically 40°F or 5°C). The blanket have to be left in area for the crucial first 24-72 hours of the curing process.

Remove and Store: After the curing period, carefully dispose of the cement blanket. If it is a reusable model, easy it in accordance to the manufacturer's guidelines and permit it to dry definitely earlier than storing it for future use.

Cement Blanket vs. Traditional Methods: A Clear Winner

Comparing a cement blanket to regular processes highlights its superiority:

●Straw and Tarps: Straw is messy, inefficient, and affords inconsistent insulation. It can blow away, get wet, and emerge as a furnace hazard. A cement blanket is neat, secure, and scientifically designed for the task.

●Insulated Tarps and Heaters: This approach requires sourcing a couple of substances and a energy supply. It creates a furnace danger and requires regular monitoring to stop overheating or underheating. The cement blanket is a single, self-contained unit with a built-in, secure warmth source.

●Enclosed Tents: Building a brief enclosure is expensive, time-consuming, and space-intensive. The cement blanket offers a direct-contact answer that is a long way extra environment friendly and much less cumbersome.

Conclusion: Your Project's Best Insurance Policy Against the Cold

In the high-stakes world of construction, unexpected issues can derail timelines and blow budgets. Cold climate provides a very foreseeable and serious hazard to concrete integrity. A cement blanket is no longer simply any other tool; it is a proactive, engineered answer that mitigates this hazard entirely. By offering constant heat, holding imperative moisture, and defending the pour with its tough, chemical-resistant concrete material exterior, it ensures your concrete achieves its designed energy and longevity.

So, can a cement blanket shop your project? When going through the chance of freezing temperatures, the reply is a resounding yes. It is a clever funding that safeguards your materials, your labor, and ultimately, your project's success. Don't let the bloodless compromise your work—embbrace the innovation of current concrete material constructing technology.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province