How to Calculate Dewatering Bag Capacity and Treatment Volume

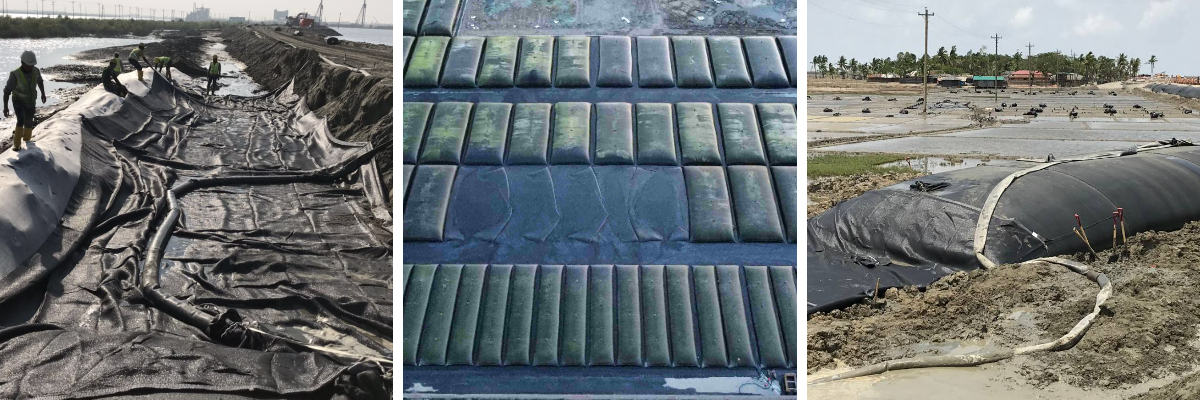

Efficient wastewater, sludge, or manure administration depends on correct planning—especially when the use of Dewatering Bags or geotextile tube systems. Miscalculating ability or remedy extent can lead to venture delays, overflow risks, and needless costs. Whether you’re treating agricultural manure, development website sludge, or industrial wastewater, appreciation how to dimension Dewatering Bags and estimate cure extent is critical. This information breaks down the key steps, considerations, and high-quality practices for calculations, whilst highlighting how Best Geotextile Tubes for Wastewater Treatment combine with these calculations to optimize results. By the end, you’ll have the equipment to sketch a dewatering gadget that meets your project’s wishes besides waste or inefficiency.

Understanding Dewatering Bag Capacity vs. Treatment Volume

Before diving into calculations, it’s vital to distinguish between two core terms: Dewatering Bags potential and therapy volume. Dewatering Bags capability refers to the most quantity of liquid/solid combination the bag can bodily hold, based totally on its dimensions. Treatment volume, via contrast, is the true quantity of waste (sludge, manure, etc.) that the bag can system effectively—accounting for dewatering efficiency, solids retention, and cloth permeability.

This difference things due to the fact now not all the cloth pumped into a dewatering bag stays inside. As water drains via the geotextile fabric, the quantity of retained solids is appreciably much less than the preliminary input. For example, a bag with a a hundred cubic meter potential would possibly solely hold 30–40 cubic meters of solids after dewatering. Similarly, geotextile tube systems, which are large and regularly used for high-volume wastewater treatment, observe the equal principle: cure quantity relies upon on each the tube’s bodily potential and its capability to separate beverages from solids.

Key Parameters for Calculating Dewatering Bag Capacity

Calculating Dewatering Bags potential starts offevolved with measuring the bag’s bodily dimensions and accounting for its shape. Most dewatering baggage are rectangular or cylindrical, and ability is commonly expressed in cubic meters or cubic feet. Here are the imperative parameters to gather:

1. Bag Dimensions

For rectangular Dewatering Bags, measure size (L), width (W), and peak (H) when the bag is stuffed (note: empty luggage might also stretch when filled, so refer to producer specs for stuffed dimensions). For cylindrical baggage or geotextile tube systems, measure diameter (D) and size (L). Always use regular gadgets (e.g., meters or feet) to keep away from errors.

2. Fill Factor

No dewatering bag ought to be crammed to one hundred percent of its theoretical capacity—overfilling can stretch the fabric, limit filtration efficiency, or purpose rupture. The fill aspect (typically 70–80% for most bags) bills for this security margin. Manufacturers frequently specify the endorsed fill top or volume, which need to take priority over theoretical calculations.

3. Fabric Expansion

Geotextile fabric (used in Dewatering Bags and geotextile tube products) amplify barely when crammed with heavy sludge or manure. Check the manufacturer’s records for growth rates—this ensures your calculations account for the bag’s real dimension for the duration of operation, no longer simply its empty dimensions.

Step-by-Step Calculation for Dewatering Bag Capacity

Once you have the key parameters, comply with these steps to calculate Dewatering Bags capacity:

Step 1: Calculate Theoretical Capacity

For rectangular bags: Theoretical Capacity = Length × Width × Height

For cylindrical bags/geotextile tube: Theoretical Capacity = π × (Diameter/2)² × Length

Example: A rectangular dewatering bag with stuffed dimensions 5m (L) × 3m (W) × 2m (H) has a theoretical capability of 5×3×2=30 cubic meters.

Step 2: Apply the Fill Factor

Multiply the theoretical capability by means of the fill component (70–80%) to get the usable capacity. Using the instance above with a 75% fill factor: Usable Capacity = 30 × 0.75 = 22.5 cubic meters. This is the most extent of liquid/solid combination the bag can safely hold.

Step 3: Adjust for Fabric Expansion

If the producer specifies a 10% growth fee for the fabric, expand the usable ability via 10%: Adjusted Capacity = 22.5 × 1.10 = 24.75 cubic meters. This ensures you account for the bag’s stretch at some stage in filling.

Calculating Treatment Volume: Accounting for Dewatering Efficiency

Treatment quantity is the quantity of waste the Dewatering Bags can method (i.e., the quantity of solids retained after dewatering). This relies upon on the waste’s solids content material and the bag’s dewatering efficiency—key elements that differentiate widespread baggage from Best Geotextile Tubes for Wastewater Treatment (which frequently have greater effectivity due to superior material designs).

1. Determine Waste Solids Content

Solids content material (expressed as a percentage) is the share of stable cloth in the waste stream. For example, manure would possibly have a 5–10% solids content, whilst development sludge may want to be 15–25%. Test the waste to get an correct solids percentage—this is critical, as low-solids waste will produce extra drainage and much less retained solids.

2. Estimate Dewatering Efficiency

Dewatering effectivity refers to the proportion of water eliminated from the waste. Dewatering Bags commonly eliminate 60–80% of water, whilst Best Geotextile Tubes for Wastewater Treatment (which use thicker, extra permeable fabrics) can acquire 75–90% efficiency. Manufacturer specs will grant effectivity rankings for unique waste types.

3. Calculate Treatment Volume

Treatment Volume = Usable Bag Capacity × (Solids Content × Dewatering Efficiency)

Example: Using the adjusted bag ability of 24.75 cubic meters, waste with 8% solids content, and 70% dewatering efficiency: Treatment Volume = 24.75 × (0.08 × 0.70) = 24.75 × 0.056 = 1.386 cubic meters of retained solids.

This potential the bag can procedure ample waste to keep ~1.39 cubic meters of solids after dewatering. For high-volume projects, geotextile tube structures (with large capacities) would scale this calculation accordingly—e.g., a 100-meter-long geotextile tube ought to technique 10–20 instances extra remedy quantity than a preferred dewatering bag.

Factors That Impact Calculations: Beyond the Numbers

While the formulation above furnish a baseline, quite a few real-world elements can have an effect on Dewatering Bags capability and cure volume. These include:

1. Waste Type and Viscosity

Thick, viscous waste (e.g., anaerobic sludge) drains extra slowly than thin, watery waste (e.g., agricultural runoff). This can minimize dewatering efficiency, so you may additionally want to alter calculations by means of 10–15% for high-viscosity materials. Best Geotextile Tubes for Wastewater Treatment regularly have large pore sizes to manage viscous waste, making them extra environment friendly in these scenarios.

2. Site Conditions

Sloped terrain can purpose uneven filling in Dewatering Bags, lowering fantastic capacity. Windy prerequisites may also dry the cloth prematurely, slowing drainage. Always stage the web page and use windbreaks if wanted to preserve steady dewatering.

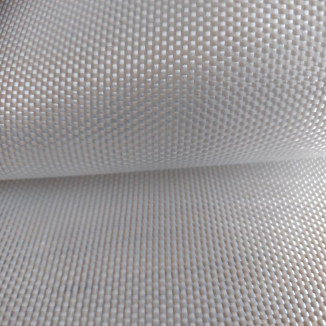

3. Fabric Type

Non-woven geotextile fabric (used in most Dewatering Bags) provide higher filtration for quality solids, whilst woven fabric (common in geotextile tube systems) permit quicker drainage for coarse solids. Choosing the proper fabric—such as these in Best Geotextile Tubes for Wastewater Treatment—ensures your calculations align with real-world performance.

Choosing the Right Product: Dewatering Bags vs. Geotextile Tubes

Your calculation effects will assist you determine whether or not Dewatering Bags or geotextile tube structures are higher for your project:

Dewatering Bags: Ideal for small-to-medium initiatives (e.g., residential septic sludge, small farm manure) with decrease therapy extent needs. They’re lightweight, effortless to install, and within your means for restricted waste streams.

Geotextile Tubes: Suited for large-scale tasks (e.g., municipal wastewater, mining sludge) with excessive therapy volumes. Best Geotextile Tubes for Wastewater Treatment provide large capacities, greater dewatering efficiency, and longer lifespans—making them within your means for bulk waste processing.

Conclusion: Accurate Calculations = Efficient Dewatering

Calculating Dewatering Bags potential and remedy extent is no longer simply about plugging numbers into formulas—it’s about perception your waste, selecting the proper geotextile product, and accounting for real-world conditions. By following the steps outlined here, you can keep away from over-sizing (which wastes money) or under-sizing (which reasons delays) your dewatering system.

Remember: Best Geotextile Tubes for Wastewater Treatment and extremely good Dewatering Bags are solely as high-quality as their sizing. Invest time in trying out your waste’s solids content, reviewing producer specifications, and adjusting for website online factors. With correct calculations, you’ll create a dewatering machine that approaches waste efficiently, reduces environmental impact, and continues your challenge on track.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province