Geofabric Installation: Common Mistakes and How to Avoid Them

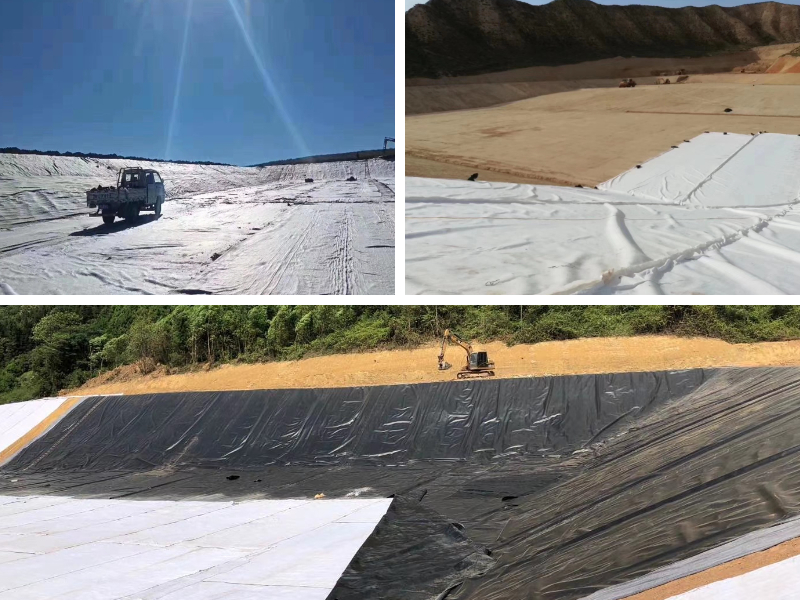

Geotextiles, frequently referred to as geofabric, are the unsung heroes of many development and landscaping projects. From stabilizing soil beneath driveways to managing drainage at the back of protecting walls, this versatile cloth is integral for long-term undertaking success. However, the overall performance of a cloth geotextile is completely established on its right installation. A single mistake can compromise its complete function, main to high priced failures.

This information will stroll you thru the most frequent geofabric set up blunders and furnish realistic recommendation on how to keep away from them, making sure your task stands the take a look at of time.

Mistake 1: Choosing the Wrong Type of Geotextile

Not all geotextiles are created equal. One of the most critical and highly-priced errors is deciding on the incorrect kind of cloth geotextile for the application.

The Problem:

Geotextiles are widely categorised into woven and non-woven types, every with wonderful properties. Using a non-woven polypropylene geotextile for a stabilization challenge the place a woven cloth is needed, or vice versa, will no longer supply the required results. Non-woven geotextiles are terrific for filtration and drainage, whilst woven ones furnish most desirable energy for separation and stabilization.

How to Avoid It:

●Identify the Primary Function: Determine the major goal. Is it separation (preventing soil and gravel from mixing), filtration (allowing water to omit whilst maintaining soil), drainage, or reinforcement?

●Understand Material Specifications: Consult technical statistics sheets for key residences like tensile strength, permeability, and puncture resistance. For heavy-load stabilization, a sturdy woven geotextile is essential. For drainage purposes subsequent to soil, a non-woven polypropylene geotextile is generally the proper choice.

●Seek Expert Advice: When in doubt, seek advice from with a civil engineer or a educated dealer who can suggest the right product primarily based on your precise soil prerequisites and challenge requirements.

Mistake 2: Inadequate Site Preparation

A cloth geotextile can't operate its magic on an unprepared surface. Installing it over rough, uneven, or debris-laden floor is a recipe for failure.

The Problem:

Sharp rocks, roots, and uneven surfaces can puncture or tear the geotextile at some stage in set up or as soon as the overlying cloth (like gravel) is placed. This creates susceptible factors the place soil can migrate, undermining the fabric's separation and filtration functions.

How to Avoid It:

●Clear and Grade: Remove all vegetation, giant stones, sticks, and any different particles from the subgrade.

●Compact and Level: Grade the soil to the favored contour and compact it properly. The intention is a smooth, firm, and steady base free of sharp protrusions.

●Final Inspection: Walk the place earlier than unrolling the polypropylene geotextile to make sure no hidden sharp objects ought to motive damage.

Mistake 3: Incorrect Placement and Overlap

How the geotextile is laid out and seamed is quintessential for developing a continuous, purposeful layer.

The Problem:

Placing the material with inadequate overlap between rolls creates gaps. These gaps turn out to be direct pathways for soil to combine with aggregate, main to rutting and instability. Conversely, immoderate overlap is a waste of cloth and can create unevenness.

How to Avoid It:

●Follow Overlap Specifications: Typically, a 12 to 18-inch (300 to 450 mm) overlap is general for most applications. Always test the manufacturer's suggestions for your precise cloth geotextile.

●Align in the Direction of Stress: When possible, orient the roll so the seam runs perpendicular to the main route of stress (e.g., car visitors on a road). This helps stop the seams from being pulled apart.

●Secure the Overlap: On slopes or in windy conditions, briefly tightly closed the overlap with staples or stakes to stop motion at some stage in backfilling. For indispensable reinforcement projects, stitching or adhesively bonding the seams of the polypropylene geotextile may additionally be necessary.

Mistake 4: Damage During Backfilling

You've chosen the proper geotextile and organized the web page perfectly. The last hurdle is putting the overlying cloth except detrimental the fabric.

The Problem:

Dropping combination or soil from a top notch peak can tear or puncture the subtle geotextile. Similarly, monitoring heavy equipment at once on the uncovered cloth can purpose rips and compromise its integrity.

How to Avoid It:

●Lift, Don't Drop: Always region the backfill fabric (gravel, sand, etc.) in managed lifts. Start by means of dumping the cloth at the edges and then unfold it inward onto the cloth geotextile.

●Maintain a Minimum Cover: Before permitting any heavy gear to force without delay on the layer, make sure there is a ample thickness of cowl material—typically at least 6 to 12 inches. This cushion layer distributes the load and protects the geotextile from punctures.

●Use Lightweight Equipment: For the preliminary spreading phase, use smaller, lighter equipment or work from the aspects to reduce direct contact with the uncovered polypropylene geotextile.

Mistake 5: Neglecting Proper Anchoring on Slopes

Installing a geotextile on a slope except acceptable anchoring is a frequent and unsafe oversight.

The Problem:

Gravity will motive the cloth to slide down the slope earlier than or at some point of backfilling. This motion creates wrinkles, eliminates tension, and can expose the soil underneath, main to erosion and failure of the complete system.

How to Avoid It:

●Start at the Top: Always start unrolling the material geotextile from the pinnacle of the slope.

●Trench Anchoring: The most positive approach is to dig a small anchor trench at the pinnacle of the slope. Place the pinnacle quit of the geotextile in the trench, backfill it, and compact the soil. This locks the complete sheet in place.

●Secure with Staples: Use panorama staples or stakes alongside the face of the slope to quickly maintain the polypropylene geotextile in region till the backfill fabric covers and secures it permanently.

Conclusion: A Stitch in Time Saves Nine

A geotextile is a high-performance engineering material, now not simply a easy piece of cloth. Its profitable utility hinges on cautious planning and meticulous installation. By appreciation and fending off these frequent mistakes—selecting the incorrect type, terrible web page prep, flawed overlap, backfill damage, and bad anchoring—you can make sure your material geotextile performs as intended.

Taking the time to deploy your polypropylene geotextile effectively is a small funding that will pay huge dividends in the longevity, stability, and success of your project. A job carried out proper the first time prevents steeply-priced repairs and ensures your shape stays strong for years to come.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province