Successful HDPE Geomembrane Project: Large-Scale Reservoir Lining for a Municipal Utility

Municipal water furnish structures are the lifeline of city operations, and large-scale reservoirs, as core water storage facilities, without delay decide the steadiness and security of water supply. In a latest large-scale reservoir renovation venture for a municipal utility, the utility of HDPE Geomembrane in reservoir lining has done awesome results, successfully fixing the troubles of water seepage, soil erosion and structural getting old of the authentic reservoir. This article will deeply dissect the key hyperlinks of the project, focusing on the benefits of Geomembrane materials, the important points of Geomembrane Installation, best manage measures and challenge value, to supply treasured reference for comparable municipal water conservancy projects.

1. Project Background: Urgent Needs for Anti-Seepage Renovation of Municipal Reservoirs

The goal reservoir of this undertaking is a key municipal water storage facility with a storage capability of five million cubic meters, challenge the water grant challenge for extra than 300,000 residents and dozens of industrial corporations in the region. After long-term operation, the authentic reservoir lining shape had serious hidden dangers: the concrete lining used to be cracked, and the soil at the backside of the reservoir used to be eroded through water, ensuing in an annual seepage loss of almost 10% of the complete storage capacity. This now not solely wastes valuable water sources however additionally threatens the structural security of the reservoir dam.

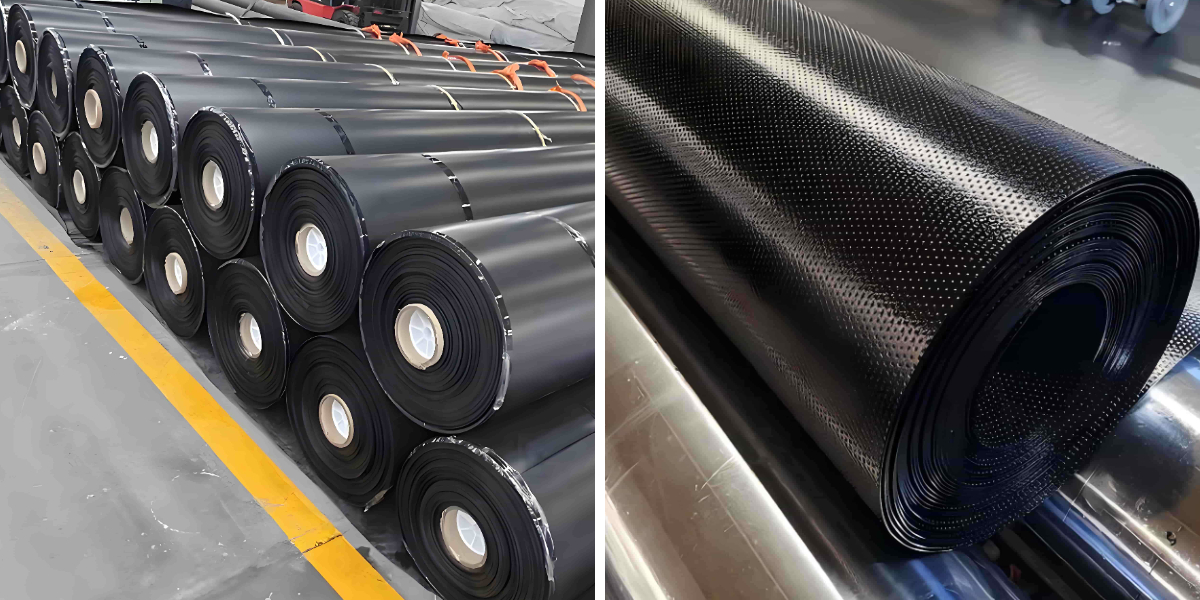

To remedy these problems, the municipal utility launched a complete renovation project, and the core mission is to pick out a high-performance anti-seepage cloth for reservoir lining. After repeated demonstrations and comparisons via expert teams, HDPE Geomembrane used to be subsequently decided as the core lining material. Compared with standard anti-seepage substances such as concrete and clay, HDPE Geomembrane has obvious blessings in anti-seepage performance, carrier lifestyles and building efficiency, which can entirely meet the long-term steady operation wishes of large-scale municipal reservoirs. The choice of this cloth has laid a stable foundation for the success of the project, and additionally displays the essential function of notable Geomembrane in present day water conservancy anti-seepage projects.

2. Core Advantage: Why HDPE Geomembrane Becomes the First Choice for Reservoir Lining

In this municipal reservoir lining project, the preference of HDPE Geomembrane is no longer accidental. Its special fabric houses and overall performance benefits make it stand out in many alternatives. First of all, HDPE Geomembrane has terrific anti-seepage performance. Its dense molecular shape can totally block the penetration of water molecules, and the seepage coefficient is as low as 10-12 cm/s, which is a ways most efficient to normal concrete and clay anti-seepage materials. This is quintessential for decreasing water loss in the reservoir and making sure the wonderful storage capacity.

Secondly, HDPE Geomembrane has sturdy corrosion resistance and environmental adaptability. The reservoir water carries a range of chemical substances, and the surrounding soil surroundings is complex. HDPE Geomembrane can face up to the erosion of acids, alkalis, salts and other chemical media, and can also adapt to the temperature modifications in the herbal surroundings (-60℃ to 80℃) except getting old or cracking. In addition, HDPE Geomembrane has excessive tensile energy and elongation at break, which can adapt to the mild deformation of the reservoir basis besides damage. The light-weight traits of the cloth additionally decrease the load on the reservoir foundation, which is of awesome importance for defending the authentic shape of the reservoir.

It is really worth bringing up that HDPE Geomembrane is a inexperienced and environmentally pleasant material, non-toxic and harmless, which will no longer pollute the reservoir water and the surrounding ecological environment. This is in line with the municipal utility's thought of "ecological water conservancy" and additionally meets the necessities of current environmental safety projects. The remarkable complete overall performance of HDPE Geomembrane has been wholly established in this project, supplying a dependable cloth warranty for the long-term anti-seepage impact of the reservoir.

3. Key Link: Standardized Geomembrane Installation Ensures Project Quality

The overall performance of HDPE Geomembrane can solely be wholly exerted via scientific and standardized Geomembrane Installation. In this large-scale reservoir lining project, the development crew formulated a strict set up sketch based totally on the proper state of affairs of the reservoir, and strictly applied every set up manner to make certain the set up quality.

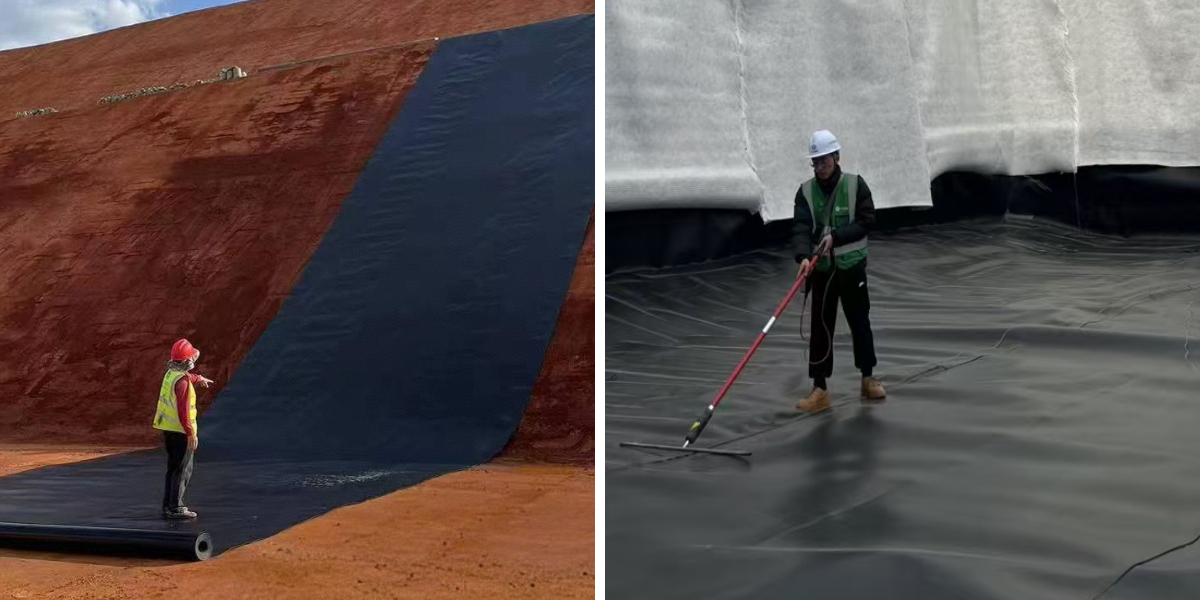

The first step of Geomembrane Installation is the cure of the base surface. The development crew first cleaned up the debris, stones and sharp objects at the backside and facet slopes of the reservoir to keep away from piercing the Geomembrane. Then, the base floor used to be leveled and compacted to make sure that the base floor was once flat and firm, and the unevenness error used to be managed inside 2cm/m. This step is the foundation of the whole set up work, and any carelessness will have an effect on the subsequent set up impact and anti-seepage performance.

Next is the laying of HDPE Geomembrane. The laying adopts the approach of "from pinnacle to bottom, horizontal laying", and the overlap width between adjoining Geomembrane sheets is managed at 10-15cm. During the laying process, the development group prevented dragging the Geomembrane forcibly to forestall the fabric from being broken via friction. At the identical time, the Geomembrane used to be laid tightly to keep away from air bubbles and wrinkles. For the nook and facet components of the reservoir, the Geomembrane was once reduce and laid in accordance to the genuine form to make certain that it suits intently with the base surface.

The welding of HDPE Geomembrane is the core of Geomembrane Installation. The undertaking adopts thermal wedge welding technology, and the welding temperature and pace are strictly managed (the temperature is 200-230℃, and the velocity is 2-3m/min). Before formal welding, the development group performed a welding take a look at on the take a look at piece to decide the optimum welding parameters. After the welding is completed, the welding seam is inspected one via one the use of the air strain check method. The take a look at stress is 0.2MPa, and the stress is maintained for 30 minutes. If there is no strain drop, the welding seam is qualified. For the unqualified welding seams, the building crew will re-weld them in time and re-inspect till they are qualified. This strict welding and inspection method ensures the integrity and anti-seepage impact of the HDPE Geomembrane lining system.

4. Quality Control: Multi-Level Supervision to Ensure Long-Term Operation of the Project

For municipal water conservancy projects, excellent is the lifeline. In this HDPE Geomembrane reservoir lining project, the municipal utility has mounted a multi-level pleasant manage system, protecting the complete method from cloth incoming inspection to building procedure supervision and post-construction acceptance, to make certain that the challenge first-class meets the format necessities and applicable countrywide standards.

In phrases of fabric incoming inspection, the development crew strictly assessments the high-quality certificate, inspection document and different files of the HDPE Geomembrane. At the equal time, it randomly samples the incoming Geomembrane and assessments the key indications such as tensile strength, elongation at smash and seepage coefficient. Only the substances that skip all the assessments can enter the building site. This ensures that the HDPE Geomembrane used in the venture is of excessive satisfactory and dependable performance.

In the development technique supervision, the task supervision crew conducts full-time on-site supervision, focusing on the key hyperlinks such as base floor treatment, Geomembrane laying and welding. For every process, the supervision personnel will behavior strict inspection earlier than the subsequent technique can be carried out. For example, after the base floor treatment, the supervision personnel will test the flatness and compactness of the base surface; all through the welding process, they will randomly test the welding parameters and welding seam pleasant to make certain that the building technique is standardized and controllable.

In the post-construction acceptance, the challenge crew carried out a complete inspection of the complete HDPE Geomembrane lining system, inclusive of visible inspection, air stress take a look at and water filling test. The visible inspection ordinarily tests whether or not there are damages, wrinkles and different defects on the floor of the Geomembrane; the air strain check rechecks the welding seam quality; the water filling take a look at simulates the true operation nation of the reservoir, and video display units the seepage loss for seventy two hours. The check effects exhibit that the seepage loss of the reservoir after renovation is much less than 0.5% of the complete storage capacity, which totally meets the format requirements. The multi-level fantastic manage measures make certain the long-term steady operation of the project.

5. Project Value: Economic, Ecological and Social Benefits Win-Win

The profitable completion of this HDPE Geomembrane large-scale reservoir lining venture has performed wonderful economic, ecological and social benefits, and has been rather identified via the municipal utility and the normal public.

In phrases of monetary benefits, the mission efficiently reduces the water seepage loss of the reservoir. Calculated by means of the authentic annual seepage loss of 10%, the annual water saving is about 500,000 cubic meters, which saves a lot of water assets and reduces the value of water grant for the municipal utility. At the identical time, the provider lifestyles of HDPE Geomembrane is extra than 50 years, which is a great deal longer than that of normal anti-seepage materials. This reduces the frequency of later renovation and renovation, and saves long-term renovation prices for the municipal utility.

In phrases of ecological benefits, the utility of HDPE Geomembrane avoids the environmental air pollution brought about by way of the building of standard concrete lining. The cloth itself is non-toxic and harmless, and will now not have an effect on the water nice of the reservoir and the surrounding ecological environment. At the equal time, lowering water seepage helps to preserve the water degree of the reservoir, guard the surrounding wetland ecosystem and the residing surroundings of aquatic organisms, and promote the stability of the ecological environment.

In phrases of social benefits, the challenge ensures the steady water furnish of the municipal water furnish system, solves the trouble of water scarcity for residents and businesses in the region, and improves the pleasant of lifestyles of residents and the manufacturing effectivity of enterprises. In addition, the secure and secure operation of the reservoir additionally enhances the city's flood manipulate and drought resistance capacity, presenting a robust warranty for the steady improvement of the city.

Conclusion

The profitable exercise of this HDPE Geomembrane large-scale reservoir lining challenge for a municipal utility has proved that HDPE Geomembrane is an best anti-seepage cloth for large-scale water conservancy projects. Scientific cloth selection, standardized Geomembrane Installation and strict satisfactory manipulate are the key to the success of the project. With the non-stop improvement of urbanization, the demand for municipal water conservancy initiatives will proceed to increase. It is believed that HDPE Geomembrane will be greater broadly used in future water conservancy anti-seepage projects, making larger contributions to the rational utilization of water sources and the secure improvement of cities

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province