Advanced Geotextile Cloth Installation Techniques for Complex Terrains (Steep Slopes, Wet Soils)

Complex terrains like steep slopes and waterlogged soils pose extensive challenges to geosynthetic installation. Poorly hooked up Geotextile Cloth fails to supply erosion control, soil stabilization, or drainage benefits—leading to pricey repairs and challenge delays. Geotextile materials, when deployed with superior strategies tailor-made to difficult conditions, end up a dependable answer for infrastructure, landscaping, and environmental projects. This information breaks down 4 vital factors of putting in Geotextile Cloth on complicated terrains, making sure long-lasting performance.

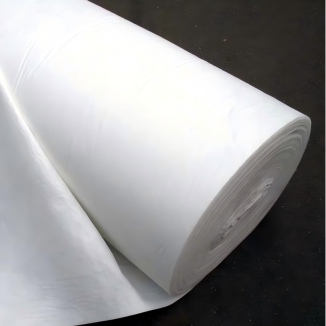

1. Pre-Installation Assessment & Geotextile Cloth Selection

Success on complicated terrains starts offevolved with focused evaluation and the proper Geotextile choice—one-size-fits-all processes assurance failure. Skipping this step dangers the use of a fabric that can’t stand up to slope shear forces or moist soil’s hydrostatic pressure.

For pre-installation assessment, focal point on key terrain metrics: behavior slope evaluation via measuring gradient (steepness over 30° requires bolstered Geotextile Cloth) and soil concord with a clinometer to map angles and unstable zones, plus shear power assessments for slopes over 45°; signify moist soils by using checking out moisture content material (target <30% for installation) and bearing capability with a penetrometer to pick out tender layers wanting pre-compaction, whilst mapping drainage patterns to keep away from water trapping; and be aware environmental elements like rainfall depth (high-precipitation areas want high-permeability Geotextile Cloth) and UV publicity (outdoor tasks require UV-stabilized materials). When deciding on Geotextile Cloth, fit homes to terrain: pick out woven Geotextile Cloth with tensile electricity ≥200 kN/m (e.g., polyester or polypropylene blends) for steep slopes, strengthened with geogrids for slope creep resistance; decide for non-woven Geotextile with permeability ≥10⁻³ cm/s for moist soils to facilitate drainage, averting fine-pore substances and the use of hydrophilic remedies for clay-heavy soils; and pick multi-layer Geotextile Cloth (woven core + non-woven filter layers) for slopes with continual moisture to stability energy and drainage.

2. Advanced Geotextile Cloth Installation on Steep Slopes

Steep slopes demand methods that forestall Geotextile slippage in the course of set up and withstand long-term gravitational forces. Traditional unrolling techniques regularly lead to fabric bunching or tearing.

For superior Geotextile Cloth set up on steep slopes, begin with slope practise by way of putting off rocks, roots, and particles to create a clean base (sharp objects puncture Geotextile materials), making use of a 5cm layer of compacted gravel or transient erosion manage blankets for free soil, and putting in drainage ditches at the slope top to redirect runoff and forestall mid-installation soil saturation; then use managed deployment methods to keep away from guide unrolling (risky for slopes >30°), such as winch-assisted unrolling (securing a winch at the pinnacle to decrease the Geotextile Cloth roll with 2-3 people guiding to keep away from wrinkles) or segmented set up (cutting into 3-5m sections, putting in bottom-up with 30cm overlaps and anchoring every section first); finally, use impervious anchoring structures (standard stakes fail here) which includes pinnacle area anchors (30cm-deep trenches for the Geotextile Cloth edge, backfilled with compacted soil or concrete), intermediate anchors (15cm metal rebar stakes at 1.5m intervals, or spiral anchors screwed 60cm deep for slopes >45°), and backside part anchors (20cm trenches or attachment to concrete toe partitions to forestall runoff uplift).

3. Geotextile Installation in Wet Soil Conditions

Wet soils minimize bearing capacity, making Geotextile Cloth set up messy and inclined to cloth misalignment. The aim is to decrease soil disturbance and make certain suited drainage to keep away from Geotextile saturation.

When putting in Geotextile in moist soil prerequisites (which limit bearing capability and purpose misalignment), first stabilize soil and prep drainage by using putting in 10cm-diameter perforated drainage pipes in 15cm trenches (adding 3cm sand above for clay soils to stop clogging) to redirect standing water, and compacting with a 1-2 ton vibratory curler (avoiding over-compaction) whilst the use of brief plywood for extraordinarily tender areas to distribute weight; next, use moist soil set up methods like roll safety (elevating Geotextile Cloth rolls on pallets and the usage of forklifts/cranes to keep away from dragging throughout moist soil), slip-resistant placement (cleated boots for workers, track-mounted installers for giant areas), and overlap sealing (waterproof adhesive on 30cm overlaps, weighted with gravel baggage till curing); finally, make certain post-installation drainage with the aid of including 60cm-deep vertical gravel drainage wells each and every 5m to launch hydrostatic strain and overlaying the Geotextile with 10cm coarse gravel inside 24 hours for safety and improved drainage.

4. Quality Control & Long-Term Maintenance

Complex terrains increase the have an effect on of set up errors. Rigorous fine assessments and proactive protection make sure Geotextile Cloth performs as meant for its 10-20 12 months lifespan.

For great manipulate and long-term upkeep (critical as complicated terrains extend errors), habits integral set up inspections which includes anxiety checking out (handheld meters to make sure Geotextile is taut however no longer overstretched, 10-15% of max tensile energy for slopes), overlap and anchoring assessments (verifying ≥30cm overlaps and impervious anchors, checking out adhesive bonds in moist soils), and injury evaluation (repairing small holes with 5cm-larger Geotextile patches and adhesive, changing sections with harm >10cm); put into effect long-term preservation practices like quarterly inspections (checking for Geotextile Cloth cracks from slope motion or standing water from drainage blockages, with immediately assessments after heavy rain) , annual drainage preservation (clearing particles from pipes/wells, flushing moist soil pipes), and restore protocols (replacing corroded/loose anchors, covering UV-damaged Geotextile as an alternative of full alternative for fee financial savings on steep slopes) to make certain 10-20 yr lifespan.

Conclusion: Master Complex Terrains with Expert Geotextile Installation

Steep slopes and moist soils don’t have to derail your project—with centered assessment, perfect Geotextile Cloth selection, and superior set up techniques, you can gain dependable soil stabilization and erosion control. The key is prioritizing terrain-specific prep, the usage of specialised deployment methods, and investing in satisfactory checks. Whether you’re working on a dual carriageway embankment, wetland restoration, or residential landscaping, Geotextile substances supply long lasting consequences when hooked up with these quality practices. Ready to handle your complicated terrain project? Start with a thorough website online evaluation to healthy the proper Geotextile Cloth to your special challenges.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province