HDPE Geomembrane Welding Tips: Ensure Strong Seams for Leak-Proof Performance

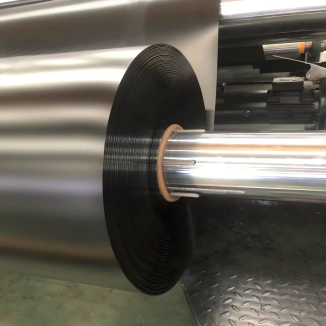

In building initiatives requiring water tightness—such as landfills, reservoirs, ponds, and wastewater therapy facilities—hdpe geomembrane stands out as a dependable barrier. However, even the highest-quality geomembrane fails if its seams are poorly welded. Seams are the most susceptible factors of any hdpe membrane installation, making perfect welding methods integral to reaching long-term leak-proof performance. Below are three core components to grasp for flawless HDPE geomembrane welding, alongside with actionable pointers to keep away from frequent pitfalls.

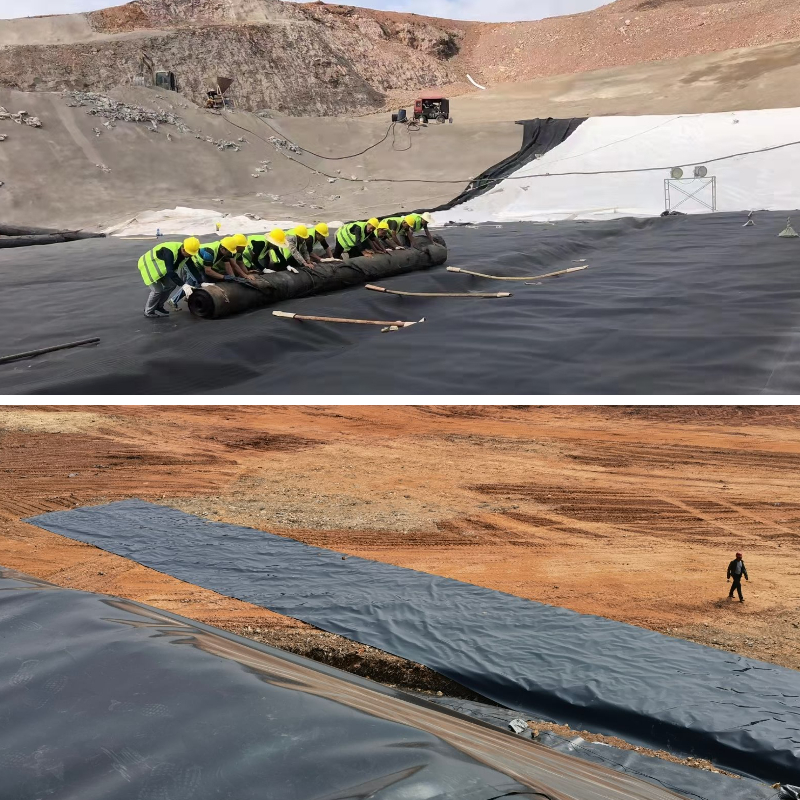

1. Pre-Welding Preparation: Lay the Foundation for Strong HDPE Membrane Seams

Rushing into welding except suitable practise is a main reason of vulnerable seams and future leaks. This stage ensures your hdpe geomembrane and work surroundings are optimized for bonding, stopping problems like terrible fusion or fabric damage.

1.1 Inspect HDPE Geomembrane Materials & Equipment

Before unrolling a single sheet of geomembrane, affirm that each the cloth and welding equipment meet task standards: take a look at the hdpe membrane itself for defects like cracks, pinholes, or floor illness (e.g., oil, dirt, or UV damage) and make certain its thickness and density healthy graph requirements, take a look at welding gear (e.g., warm wedge welders, extrusion welders) through calibrating them to producer guidelines, checking heating issue temperatures (typically 250–300°C for HDPE) and adjusting strain settings (15–25 psi for most seams) to keep away from underheating or overheating, and put together backup equipment like a handheld extrusion welder for repairing small gaps or reinforcing seams in hard-to-reach areas such as corners or round pipes.

1.2 Prepare the Installation Base for Geomembrane

A smooth, easy base prevents the hdpe geomembrane from moving throughout welding and avoids punctures that should compromise seams: stage the floor via putting off rocks, roots, or particles large than 25mm (even small sharp objects can create anxiety in the membrane, main to uneven seams) and the use of a curler to compact the base (e.g., sand or gravel) to decrease agreement over time, then smooth the 10–15cm overlap location of each hdpe membrane sheet with a lint-free material and isopropyl alcohol—oil, dust, or moisture right here will block fusion, ensuing in gaps between sheets.

1.3 Control Environmental Conditions

Weather and temperature without delay have an effect on HDPE welding results, so in no way weld hdpe geomembrane in excessive conditions: purpose for an perfect temperature vary of 10–30°C (below 10°C, HDPE will become brittle and seams crack easily; above 30°C, the membrane may additionally stretch or warp at some stage in handling) and keep away from welding when wind speeds exceed 10 km/h (wind can blow debris onto seams or cool heating factors too quickly) or when it rains or humidity is excessive (moisture prevents acceptable fusion), the use of a transient safe haven to cowl the work location if climate turns bad.

2. Choose the Right Welding Technique for HDPE Geomembrane: Tailor to Project Needs

No single welding technique works for all hdpe geomembrane installations. The method you choose relies upon on the membrane’s thickness, mission size, and web page constraints. Mastering these three frequent techniques ensures seams are robust and leak-proof.

2.1 Hot Wedge Welding: For Large-Area HDPE Membrane Installations

Hot wedge welding is the most environment friendly preference for long, straight seams in massive initiatives (e.g., reservoirs or landfills) with hdpe geomembrane thicknesses of 1.5–3mm, as it makes use of a heated metallic wedge to soften overlapping membrane edges and then applies stress with rubber rollers to fuse them; key pointers encompass retaining a regular welding pace (1.5–3 meters per minute) to keep away from overheating (which reasons bubbling) or underheating (which leads to vulnerable fusion), monitoring the wedge temperature intently (270–280°C for 2mm-thick geomembrane, 290–300°C for 3mm sheets) to make certain full melting, and inspecting the weld bead (the raised plastic line alongside the seam) as you go— a uniform, clean bead suggests appropriate fusion, whilst a lumpy or lacking bead capacity velocity or temperature wishes adjustment.

2.2 Extrusion Welding: For Thick HDPE Geomembrane & Repairs

Extrusion welding is designed for thicker hdpe membrane (3mm or more) and for repairing defects in present seams, working by using melting a separate HDPE rod and extruding it into the hole between two membrane edges to create a strong, strengthened bond; key recommendations consist of preheating the membrane edges with a warm air gun earlier than extruding to soften the base fabric (ensuring the weld rod fuses with the hdpe geomembrane instead of simply sitting on top), the usage of the right rod dimension (matching the rod’s diameter to the membrane’s thickness, e.g., 3mm rod for 3mm membrane) to keep away from inadequate hole filling or extra cloth buildup, and smoothing the weld with a trowel whilst it’s nonetheless heat to put off air pockets and make certain the seam is flush with the membrane surface.

2.3 Hot Air Welding: For Small, Detailed Geomembrane Work

Hot air welding is best for tight areas (e.g., round manholes or corners) and thin geomembrane (1–1.5mm), the use of a circulate of warm air to soften membrane edges that are then pressed collectively with the aid of hand or with a roller; key suggestions encompass preserving the warm air nozzle 5–10cm from the membrane floor (holding it too shut burns the material, too a long way prevents melting), the usage of a strain curler at once after heating to practice firm, even strain for 5–10 seconds (critical for thin hdpe membrane, which cools quickly) to make sure full fusion, and heading off overlapping welds via leaving a 2cm hole between passes for joints requiring more than one passes (prevents overheating and cloth degradation).

3. Post-Welding Quality Inspection: Verify Leak-Proof Performance of HDPE Membrane Seams

Even the high-quality welding work wants verification. Skipping post-weld inspection dangers lacking hidden leaks that solely grow to be obvious months or years later. Use these 4 strategies to verify your hdpe geomembrane seams meet enterprise requirements (e.g., ASTM D7004 for HDPE welding).

3.1 Visual Inspection: Catch Obvious Defects

Start with a thorough visible test of each and every seam—this takes little time however identifies easy-to-fix issues: seem to be for uneven weld beads, gaps between the membrane and weld, or signs and symptoms of burning (discolored plastic) (these point out negative temperature or pace manipulate at some stage in welding), test for "cold spots" (dull, unmelted areas) on the seam (cold spots mean hdpe membrane edges didn’t fuse accurate and will leak beneath pressure), and check out restore areas to make certain extrusion welds are smooth, cowl the whole defect, and have no cracks or air bubbles.

3.2 Air Pressure Test: Validate Seam Tightness

The air strain take a look at is the gold trendy for checking hdpe geomembrane seam integrity, working by using sealing a area of the seam and injecting air to measure strain retention; to function it, seal each ends of a 1–2 meter seam part with hermetic plugs, inject air till the strain reaches 20–25 psi (per venture specifications), then wait 10 minutes—if stress drops by using greater than 5%, the seam has a leak, so use soapy water to discover the leak (bubbles structure at the gap) and restore it with an extrusion welder.

3.3 Vacuum Box Test: For Large, Flat HDPE Membrane Seams

For vast seams (e.g., 30cm overlaps) or massive mission areas, the vacuum field check is greater environment friendly than air strain testing, the usage of a transportable vacuum container to create terrible strain over the seam and draw air via leaks; to function it, observe a soapy water solution to the seam, region the vacuum container over the seam and flip on the vacuum (create -5 to -10 kPa pressure), then watch for bubbles—any effervescent shows a leak, so mark the spot and restore it immediately.

3.4 Spark Test: Detect Pinholes in HDPE Membrane

Pinholes (tiny holes in the membrane or seam) are invisible to the bare eye however motive slow, continual leaks, and the spark check makes use of a high-voltage probe to observe these defects; to function it, floor the hdpe geomembrane to a metallic stake, ignore the spark probe (set to 10–15 kV) 1–2cm above the seam, and word if a spark jumps from the probe to the membrane—this suggests a pinhole, so mark the vicinity and patch it with a small piece of geomembrane welded in place.

Final Thoughts: Invest in Quality Welding for Long-Lasting HDPE Geomembrane Performance

A hdpe geomembrane’s leak-proof potential relies upon completely on its seams. By prioritizing pre-welding preparation, deciding on the proper approach for your project, and conducting rigorous post-weld inspections, you make certain your hdpe membrane installation stands the check of time—whether it’s defending a landfill from contaminating groundwater or maintaining a reservoir full.

For project-specific guidance, continually seek advice from the geomembrane manufacturer’s welding pointers and educate your crew on acceptable device use. Even small investments in coaching and guidance store high priced repairs and environmental dangers later.

If you want a customizable HDPE Geomembrane Welding Checklist to streamline your on-site process—including cloth inspection checkpoints and step-by-step take a look at procedures—let me create one for you. It will assist your group remain regular and keep away from neglected steps at some point of set up.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province