Geotube Dewatering Best Practices: A Step-by-Step Guide for Optimal Results

Geotube dewatering has emerged as a distinctly environment friendly and low-priced answer for managing sludge and wastewater throughout numerous industries, which includes municipal wastewater treatment, mining, construction, and environmental remediation. By adhering to fantastic practices, operators can make sure most water removal, decrease processing time, and lengthen the lifespan of equipment. This complete step-by-step information delves into the fundamental levels of geotube dewatering, presenting actionable insights to obtain most beneficial results.

1. Site Preparation and Planning

1.1 Evaluate Site Conditions

Before initiating any geotube dewatering project, habits a thorough website assessment. Start by way of examining the topography—sloped areas might also require grading to create a flat surface, as uneven floor can purpose uneven stress distribution on the Dewatering Geotube, main to untimely failure. Test the soil bearing capacity; if the soil is tender or sandy, lay a layer of non-woven geotextile cloth below the tube to forestall sinking and beautify stability. Additionally, test for attainable boundaries such as rocks, debris, or sharp objects, which can puncture the geotube material. Clear the website online utterly to create a smooth, hazard-free base.

1.2 Plan for Water Disposal

Develop a unique water disposal approach to take care of the filtrate (the water expelled from the geotube). The filtrate may additionally incorporate hint contaminants, so it’s crucial to direct it to an excellent therapy facility, retention pond, or authorized discharge point. Install perimeter drainage channels round the geotube to accumulate the filtrate efficiently, making sure they have a minimal slope of 2% to stop pooling. For tasks in ecologically touchy areas, think about including a secondary filtration layer, such as geotextile dewatering bags, to similarly purify the filtrate earlier than release. Always confirm compliance with neighborhood environmental policies related to water discharge requirements to keep away from penalties.

2. Selecting the Right Dewatering Geotube

2.1 Match Size to Sludge Volume

Choosing the right Dewatering Geotube measurement is necessary for environment friendly operation. Calculate the whole extent of sludge to be processed, thinking about each the preliminary quantity and its moisture content. As a well-known rule, the geotube have to have a potential 1.5 to two instances the extent of the sludge to account for growth for the duration of filling. For example, if processing one hundred cubic meters of sludge with 95% moisture content, a geotube with a 150–200 cubic meter capability is ideal. Larger initiatives may also require a couple of interconnected tubes, but make sure there’s at least three meters of area between every tube for tools get right of entry to and airflow. Consult producer specifications, as specific fashions are designed to manage various sludge densities—heavier sludges (e.g., mining tailings) may additionally require strengthened tubes with greater tensile strength.

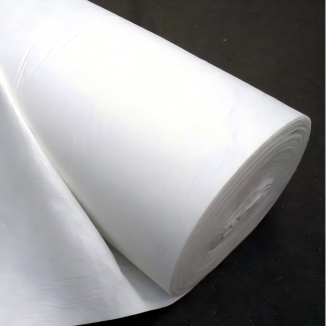

2.2 Choose Appropriate Fabric Type

Geotubes are built from both woven or non-woven geotextile fabrics, every with wonderful advantages. Woven fabrics, made from high-strength polypropylene threads, provide exceptional sturdiness and fast water drainage, making them appropriate for coarse sludges with large particles, such as development particles or sand-laden wastewater. Non-woven fabrics, composed of bonded polypropylene fibers, have smaller pores that efficaciously entice best particles, making them best for fine-grained sludges like municipal biosolids or industrial wastewater. For sludges with excessive natural content, decide for UV-stabilized fabric to withstand degradation from extended publicity to sunlight. This cautious resolution ensures each the geotube dewatering gadget and auxiliary geotextile dewatering luggage function at top efficiency.

3. Geotube Installation and Securing

3.1 Unfolding and Positioning

When unfolding the Dewatering Geotube, cope with it with care to keep away from detrimental the fabric. Use a forklift with soft-tipped tines or a crane with a spreader bar to elevate the tube, and decrease it gently onto the organized site. Never drag the tube throughout the ground, as this can abrade the cloth and compromise its integrity. Position the tube such that the filling ports are effortlessly on hand to pumping equipment, generally inside 5–10 meters. Ensure there’s sufficient house around the tube—at least 6 meters on all sides—to accommodate filling hoses, preservation personnel, and post-dewatering maintenance activities. For initiatives requiring a couple of tubes, organize them in a grid sample with equal spacing to facilitate uniform processing.

3.2 Securing the Tube

Properly securing the geotube is integral to stop transferring throughout filling and dewatering. For small to medium-sized tubes, pressure 12-inch metal stakes round the perimeter, spacing them 1–2 meters apart, and anchor the tube’s edges to the stakes the usage of heavy-duty nylon straps. For large tubes or tasks in windy areas, use sandbags (each weighing 30–50 pounds) positioned alongside the edges, overlapping them by means of 50% to create a impenetrable seal. When connecting a couple of tubes, use interlocking anxiety straps rated for at least 5,000 kilos of pressure to make sure they continue to be aligned. Regularly investigate the securing machine all through filling—if straps start to loosen, tighten them at once to forestall leaks or uneven bulging.

4. Sludge Filling and Chemical Conditioning

4.1 Control Filling Rate and Pressure

Maintaining specific manipulate over the filling procedure is key to profitable geotube dewatering. Use a nice displacement pump with a variable velocity controller to adjust the go with the flow rate, aiming for 50–100 gallons per minute (GPM) for most standard-sized tubes. Never exceed a stress of 30 psi, as excessive stress can reason the geotube to rupture or the seams to split. Fill the tube in layers of 1–2 feet, permitting every layer to dewater for 24–48 hours earlier than including the next. This incremental filling approves water to drain gradually, decreasing inner strain and enhancing solids retention. During filling, display the tube’s shape—if it starts offevolved to bulge excessively in one area, pause filling and regulate the pump’s role to distribute sludge greater evenly.

4.2 Optimize Chemical Conditioning

For sludges with excessive viscosity or quality particles (e.g., activated sludge, clay-rich mining waste), chemical conditioning is fundamental to beautify dewatering efficiency. Polymers and flocculants are the most regularly used additives—anionic polymers work nice for inorganic sludges, whilst cationic polymers are extra high-quality for natural sludges. Conduct jar checks to decide the gold standard dosage: combine 1 liter of sludge with various polymer concentrations (typically 0.1–1.0 grams per liter) and look at floc formation. The best dosage will produce large, dense flocs that settle quickly. Add the polymer to the sludge movement the use of a metering pump, making sure thorough mixing earlier than it enters the geotube. Avoid over-conditioning, as extra polymer can coat the geotube’s pores, lowering water permeability—a frequent trouble that additionally influences geotextile dewatering bags.

5. Dewatering Monitoring and Post-Processing

5.1 Track Dewatering Progress

Implement a each day monitoring events to tune the geotube dewatering process. Inspect the tube for symptoms of leaks, such as moist spots round the base or tears in the fabric—address leaks right now by means of patching with geotextile restore tape. Measure the filtrate waft price the usage of a drift meter; a surprising drop in glide can also point out clogged pores, requiring a discount in polymer dosage. Use a moisture meter to check the sludge’s solids content material at a couple of factors on the tube—dewatering is commonly whole when the solids content material reaches 20–40%, relying on the sludge type. For municipal biosolids, goal for 25–30% solids, whilst mining sludges can frequently attain 35–40%. Keep a log of day by day measurements to perceive traits and regulate tactics as needed.

5.2 Handle and Dispose of Solids Safely

Once dewatering is complete, safely dispose of and dispose of the solidified sludge. Use a utility knife with a rounded tip to reduce the geotube fabric, making incisions parallel to the seams to keep away from unfavourable the structural integrity of the tube (if reuse is planned). Load the dewatered solids into sealed containers or vans for transport, making sure they meet neighborhood disposal regulations—some sludges may also require trying out for heavy metals or pathogens earlier than disposal. If reusing the geotube, smooth it totally with high-pressure water (2,000–3,000 psi) to do away with residual solids, then check out for tears or wear. Small holes can be patched with geotextile restore kits, whilst severely broken tubes must be changed to keep dewatering efficiency.

By following these particular first-class practices, geotube dewatering operations can reap ultimate results, from quicker water elimination to decreased operational costs. Whether making use of a Dewatering Geotube for large-scale industrial tasks or geotextile dewatering baggage for smaller applications, interest to element at each and every stage ensures dependable overall performance and long-term success.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province