Common Mistakes to Avoid When Using Cement Blankets

Common Mistakes to Avoid When Using Cement Blankets

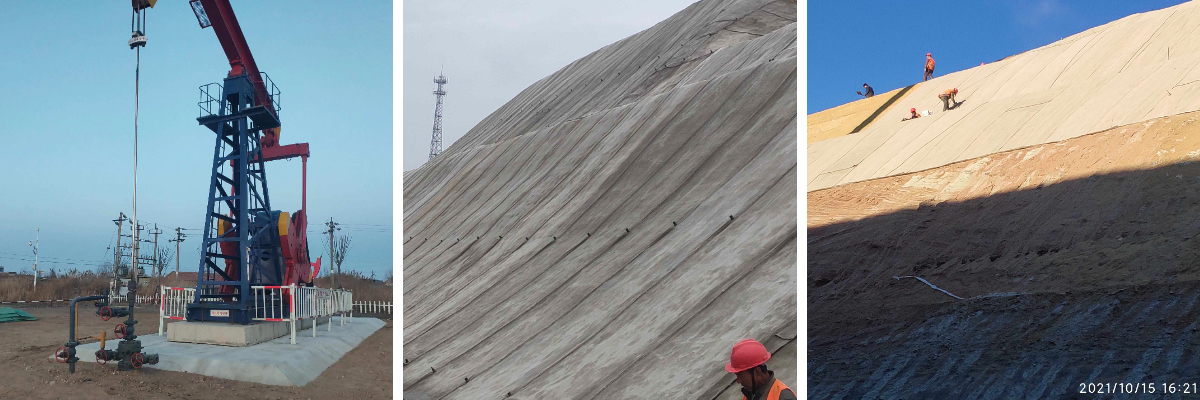

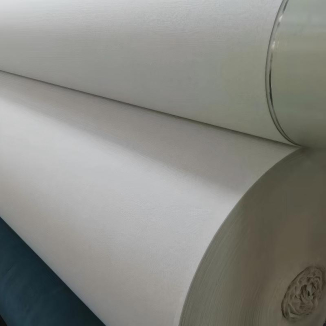

Cement blankets, such as specialised editions like Concrete Cloth and Cement Curing Blankets, have revolutionized construction, repair, and landscaping projects. Their ease of use, speedy setting, and sturdiness make them a go-to answer for the whole lot from erosion manipulate to emergency infrastructure repairs. However, even with their undemanding design, many authorities and DIY fans fall prey to frequent errors that compromise assignment quality, safety, and cost-effectiveness. In this guide, we’ll spoil down the most imperative mistakes to keep away from when working with cement blankets—whether you’re the usage of widespread Cement Canvas or application-specific preferences like Cement Curing Blankets—and how to make certain profitable effects each and every time.

1. Choosing the Wrong Type of Cement Blanket for the Project

One of the most foundational errors is choosing a one-size-fits-all cement blanket except matching it to the project’s special needs. Cement blankets come in more than a few formulations and designs, every optimized for precise applications. For example, Concrete Cloth is engineered for structural reinforcement and everlasting installations, such as preserving partitions or bridge abutments, whilst Cement Curing Blankets are designed to preserve finest moisture stages at some stage in the curing technique of freshly poured concrete, stopping cracking and making sure power development.

Many customers mistakenly use a fundamental cement blanket for curing applications, which fails to supply the vital moisture retention, main to vulnerable concrete and luxurious repairs. Conversely, the use of Cement Canvas for brief curing duties is overkill and wastes resources. Before starting, examine key factors: Is the venture everlasting or temporary? Does it require structural support, erosion control, or curing? What are the environmental prerequisites (e.g., excessive temperatures, excessive moisture)? Consulting product specs to suit the cement blanket’s properties—such as tensile strength, putting time, and water resistance—to your project’s necessities will keep away from this high priced error.

2. Inadequate Site Preparation Before Installation

Cement blankets operate pleasant on clean, stable, and suitable graded surfaces—but many customers omit integral website online practise steps, main to uneven installations, negative adhesion, and untimely failure. This mistake is in particular damaging when working with Concrete Cloth, which depends on a stable base to switch structural hundreds effectively.

Common website education oversights include: leaving particles (rocks, vegetation, or free soil) on the surface, ignoring floor grading (which reasons water pooling and uneven curing), and failing to compact the substrate. For example, if you’re putting in Cement Canvas for a slope stabilization project, an uncompacted base will shift over time, developing wrinkles or gaps in the blanket that compromise its erosion manage capabilities. For Cement Curing Blankets, a soiled or uneven floor can entice air pockets, main to inconsistent curing and vulnerable spots in the concrete.

To avoid this, comply with these steps: Clear the website of all debris, vegetation, and unfastened material. Grade the floor to make sure applicable drainage (away from buildings or touchy areas). Compact the substrate the usage of a tamping tool or compactor to create a firm, secure base. For uneven surfaces, use a skinny layer of sand or gravel to degree the vicinity earlier than laying the cement blanket.

3. Improper Watering: Too Little or Too Much Moisture

Cement blankets prompt and therapy with water, however reaching the proper moisture stability is critical—too little or too plenty water ruins the material’s properties. This is a everyday mistake throughout all cement blanket types, from Concrete Cloth to Cement Curing Blankets, and frequently stems from a lack of perception of the material’s water requirements.

Too little water skill incomplete activation: the cement matrix won’t thoroughly hydrate, main to weak, brittle consequences that without difficulty crack or crumble. On the different hand, immoderate water dilutes the cement paste, decreasing energy and inflicting segregation (where aggregates separate from the cement). For Cement Curing Blankets, overwatering can saturate the concrete, slowing curing and growing the danger of floor defects like efflorescence (white, powdery deposits).

The answer varies barely by way of product: For Concrete Cloth and general Cement Canvas, observe the manufacturer’s suggestions for water volume—typically, you want to absolutely moist the blanket till it’s uniformly saturated (no dry spots) however no longer dripping excessively. Use a low-pressure hose to keep away from detrimental the blanket’s fibers. For Cement Curing Blankets, the intention is to hold consistent moisture besides soaking the concrete; mist the blanket usually if it begins to dry out, in particular in warm or windy conditions.

4. Ignoring Environmental Conditions During Installation and Curing

Environmental factors—temperature, humidity, wind, and precipitation—have a considerable affect on cement blanket performance, but many customers proceed with set up regardless of conditions. This mistake is specially volatile with Cement Curing Blankets, which are designed to adjust curing conditions, however can’t overcome excessive environments on their own.

Extreme bloodless (below 40°F/4°C) slows or stops cement hydration, main to delayed putting and decreased strength. In hot, dry, or windy conditions, water evaporates too quickly, inflicting the cement blanket to dry out earlier than full curing—resulting in cracking, shrinkage, and vulnerable bonds. Rain or standing water all through set up can wash away cement paste, whilst extended moisture after set up can lead to mould or mildew on non-breathable blankets.

To mitigate environmental risks: Avoid putting in cement blankets in excessive temperatures (use heated enclosures in bloodless weather, or installation at some stage in cooler components of the day in warm weather). In windy or dry conditions, mist the vicinity round the blanket to make bigger humidity and sluggish evaporation. For Cement Curing Blankets, use extra insulation (like straw or foam boards) in bloodless climate to continue heat. If rain is expected, cowl the set up blanket with a water resistant tarp till it’s totally set.

5. Incorrect Cutting and Shaping of the Cement Blanket

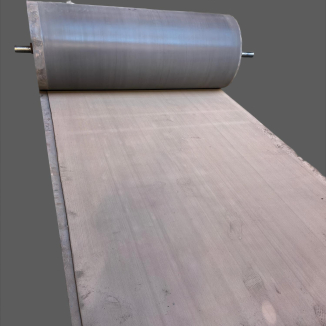

Cement blankets are frequently reduce or formed to suit irregular surfaces (e.g., pipes, corners, or uneven terrain), however unsuitable reducing methods can weaken the cloth and create vulnerabilities. This is a frequent mistake with Concrete Cloth, which has a bolstered fiber shape that, when damaged, loses its tensile strength.

Common reducing blunders include: the use of stupid equipment (which fray the fiber matrix), slicing the blanket after activation (when the cement is setting, main to uneven edges and cracking), and making overly small or jagged cuts that don’t in shape the floor properly. For example, slicing Cement Canvas with a stupid knife can go away unfastened fibers that don’t bond exact when activated, growing gaps that enable water penetration and erosion.

The right method is to reduce the cement blanket earlier than activation (while it’s dry) the use of sharp, serrated equipment (like a utility knife or hacksaw) for clean, straight edges. Measure twice and reduce as soon as to make certain a unique fit—leave a small overlap (1-2 inches) for seams to make certain full coverage. For curved surfaces (e.g., pipes), make small, evenly spaced slits alongside the curve to enable the blanket to conform except wrinkling. Avoid slicing the blanket into slim strips that can’t help their very own weight all through installation.

6. Poor Seam and Overlap Installation

Seams and overlaps are the weakest factors in any cement blanket installation, but many customers rush this step, main to water intrusion, erosion, and structural failure. This mistake is fundamental for each Concrete Cloth (used in structural applications) and Cement Curing Blankets (where gaps can expose concrete to drying out).

Common seam mistakes include: inadequate overlap (less than the manufacturer’s advocated 6-12 inches), failing to seal seams properly, and overlapping in the incorrect route (e.g., in opposition to the glide of water, which permits water to seep underneath the blanket). For example, when putting in Cement Canvas on a slope, overlapping the top blanket over the lower one (instead of the different way around) creates a “shingle effect” that diverts water away from seams. Failing to do this can lead to water pooling beneath the blanket, washing away the substrate and inflicting the set up to shift.

To make certain robust seams: Follow the manufacturer’s overlap pointers (typically 6-12 inches for horizontal seams, 12 inches for vertical seams on slopes). For Concrete Cloth, use a like minded cement-based sealant on seams to beautify adhesion. For Cement Curing Blankets, make sure overlaps are tight and tightly closed (use stakes or weights if needed) to stop wind from lifting the edges and exposing the concrete. Always overlap in the route of water float (uphill to downhill) to forestall water intrusion.

7. Rushing the Curing Process

Cement blankets require time to wholly treatment and boost their most strength, however many customers rush to put the vicinity into use—compromising the material’s long-term durability. This mistake is specially frequent with Cement Curing Blankets, the place customers might also dispose of the blanket too early, questioning the concrete is set.

Cement blankets (including Concrete Cloth and Cement Canvas) normally require 24-48 hours of curing time underneath most excellent stipulations (70°F/21°C, reasonable humidity) to attain enough strength. In cooler or drier conditions, curing time may additionally double. Removing Cement Curing Blankets too early, or putting weight on newly set up Concrete Cloth, can motive cracking, indentations, or even entire failure.

To keep away from speeding curing: Plan your assignment to permit sufficient curing time—avoid scheduling heavy use or extra development on the place till the blanket is totally cured. For Cement Curing Blankets, go away the blanket in vicinity for at least 7 days (or as encouraged by way of the concrete manufacturer) to make sure full energy development. In bloodless weather, lengthen curing time and use insulation to hold regular temperatures. Avoid strolling or riding on newly set up cement blankets till they’re utterly set.

8. Neglecting Post-Installation Inspection and Maintenance

Many customers anticipate that as soon as the cement blanket is hooked up and cured, the job is done—but neglecting post-installation inspection and protection can lead to minor troubles turning into principal problems. This is a mistake that applies to all cement blanket types, from Concrete Cloth used in structural initiatives to Cement Curing Blankets used in residential concrete work.

Common post-installation oversights include: failing to look at for cracks, gaps, or free edges; ignoring water pooling round the installation; and no longer addressing minor harm promptly. For example, a small crack in Concrete Cloth can enlarge over time due to water intrusion and freeze-thaw cycles, main to structural instability. A unfastened facet on a Cement Curing Blanket (if left in region in the course of curing) can create a vulnerable spot in the concrete that cracks beneath pressure.

To keep your cement blanket installation: Conduct a thorough inspection 24-48 hours after curing—check for cracks, gaps, free edges, or symptoms of water intrusion. Seal small cracks or gaps with a well matched cement-based sealant. For large troubles (e.g., full-size cracks or shifting), seek advice from a expert to restore or substitute the affected area. Regularly check out the set up after extreme climate (heavy rain, frost, or excessive winds) and tackle any harm immediately.

Conclusion: Avoid These Mistakes for Successful Cement Blanket Projects

Cement blankets—including Concrete Cloth, Cement Curing Blankets, and Cement Canvas—offer unparalleled comfort and overall performance when used correctly. By keeping off these frequent mistakes—choosing the incorrect type, insufficient website online preparation, incorrect watering, ignoring environmental conditions, flawed cutting, terrible seams, dashing curing, and neglecting maintenance—you can make sure your challenge is strong, durable, and cost-effective.

Remember, the key to success with cement blankets is preparation, following producer guidelines, and endurance for the duration of curing. Whether you’re a expert contractor or a DIY enthusiast, taking the time to keep away from these blunders will end result in a undertaking that stands the take a look at of time. For greater pointers on the use of cement blankets and different building materials, continue to be tuned to our blog.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province