Geomembrane Liner for Landfills: Key Features to Ensure Leakage Prevention

Landfills are fundamental for waste management, however they pose great environmental dangers if no longer desirable contained. Leaks from landfills can contaminate soil, groundwater, and close by ecosystems, making nice containment structures non-negotiable. A super geomembrane liner is the first line of defense, designed to stop hazardous leachate from escaping. In this guide, we’ll discover the key elements of landfill geomembranes that make certain dependable leakage prevention, with a center of attention on impermeable geomembrane liner and geomembrane waterproofing technologies.

1. Material Composition: The Foundation of Impermeability

The desire of cloth immediately affects a geomembrane liner’s capability to stop leaks. For landfills, two substances stand out for their finest performance:

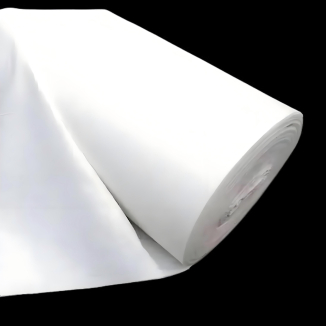

High-Density Polyethylene (HDPE) Geomembranes

HDPE is the most broadly used cloth for landfill liners, valued for its incredible chemical resistance and low permeability. A fine geomembrane liner made from HDPE elements a dense molecular shape that blocks liquid and gasoline penetration, even when uncovered to aggressive leachate containing acids, solvents, and heavy metals. Its flexibility permits it to conform to uneven landfill terrain, lowering gaps that ought to lead to leaks.

Impermeable Geomembrane Liner: Beyond Basic Barriers

An impermeable geomembrane liner regularly consists of strengthened layers or components to beautify performance. For example, textured HDPE liners add friction, stopping slippage on steep landfill slopes—a frequent motive of liner injury and subsequent leaks. Some liners additionally comprise UV stabilizers to withstand degradation from sunlight, making sure long-term integrity in uncovered landfill caps.

Compatibility with Waste Types

Different landfills deal with various waste streams, from municipal strong waste to industrial hazardous waste. A dependable geomembrane liner should be chemically like minded with the precise waste it contains. For instance, liners for hazardous waste landfills require greater thickness and chemical-resistant formulations to face up to corrosive leachate, whilst these for non-hazardous waste can stability overall performance with fee efficiency.

2. Thickness and Durability: Withstanding Landfill Stress

A geomembrane liner’s thickness and sturdiness are quintessential for resisting the bodily stresses of landfill operations.

Optimal Thickness for Long-Term Protection

Landfill geomembranes generally vary from 0.75mm to 2.0mm in thickness, with thicker liners used in high-risk areas. A thicker geomembrane liner provides higher puncture resistance, defending towards sharp objects in waste, heavy gear traffic, and settling of the landfill base. For example, a 1.5mm HDPE liner can face up to increased compressive forces than a thinner alternative, lowering the danger of tears that motive leaks.

Resistance to Wear and Tear

Landfills are dynamic environments, with consistent waste deposition, compaction, and settlement. A long lasting impermeable geomembrane liner should withstand abrasion from waste movement, punctures from debris, and stress from soil or waste weight. Reinforced geomembranes, which mix polymer layers with material meshes, add tensile strength, stopping stretching and tearing throughout landfill enlargement or settlement.

3. Seam Integrity: The Critical Link in Waterproofing

Even the great geomembrane cloth fails if seams are poorly constructed. Geomembrane waterproofing depends closely on seamless or expertly welded joints to do away with leakage points.

Advanced Welding Techniques

Thermal fusion welding is the gold general for becoming a member of geomembrane panels in landfills. Hot air or extrusion welding melts the liner edges, developing a molecular bond that is as sturdy as the liner itself. Properly welded seams have zero permeability, making sure leachate can't seep via gaps. Automated welding machines preserve steady warmness and pressure, decreasing human error in contrast to guide methods.

Seam Testing and Quality Control

After welding, each and every seam should endure rigorous checking out to affirm integrity. Non-destructive checks like air stress checking out or vacuum checking out notice tiny leaks that should compromise the liner. For high-risk areas, damaging trying out of pattern seams ensures weld electricity meets enterprise standards. This meticulous nice manipulate is why a well-installed geomembrane liner with top examined seams has a leakage charge as low as 0.001 liters per rectangular meter per day.

4. Design Adaptability: Custom Solutions for Landfill Terrain

Landfills hardly ever have uniform terrain, making sketch adaptability a key function of high-quality geomembrane liners.

Conformability to Irregular Surfaces

A first-class impermeable geomembrane liner ought to flex and conform to slopes, depressions, and contours in the landfill base. This adaptability prevents bridging—where the liner pulls away from the ground, growing voids that acquire leachate. Textured liners enhance grip on slopes, whilst pre-fabricated panels decrease the wide variety of seams needed, minimizing leak dangers in complicated terrain.

Compatibility with Composite Systems

Landfill liners regularly work in tandem with different components, such as geotextiles, drainage layers, and clay liners, to shape a composite barrier. A geomembrane liner have to combine seamlessly with these materials. For example, a non-woven geotextile positioned underneath the geomembrane protects it from punctures, whilst an overlying drainage layer collects leachate, lowering stress on the liner and decreasing leak risks.

5. Regulatory Compliance: Meeting Standards for Safety

Adherence to enterprise requirements is non-negotiable for making sure geomembrane liners stop leaks.

Global and Local Standards

Reputable geomembrane liner producers comply with requirements like ASTM D6397 (for HDPE liners) or EN 13592 (European standards), which specify overall performance necessities for thickness, tensile strength, and permeability. Landfill operators have to additionally observe nearby regulations, which regularly mandate minimal liner thickness, welding standards, and post-installation trying out to defend groundwater resources.

Third-Party Certification

Independent certification ensures geomembranes meet or exceed security benchmarks. Look for liners licensed with the aid of companies like the Geosynthetic Institute (GSI) or International Organization for Standardization (ISO), which confirm that geomembrane waterproofing claims are backed by way of rigorous testing.

Conclusion: Investing in Quality for Leak-Free Landfills

A geomembrane liner is the cornerstone of landfill containment, and its capacity to stop leaks relies upon on cloth quality, thickness, seam integrity, sketch adaptability, and regulatory compliance. By prioritizing an impermeable geomembrane liner with superior geomembrane waterproofing features, landfill operators can guard ecosystems, keep away from steeply-priced environmental fines, and prolong landfill lifespans. When it comes to leakage prevention, slicing corners on geomembrane great is by no means well worth the risk—invest in a liner that gives you reliability, durability, and peace of mind.