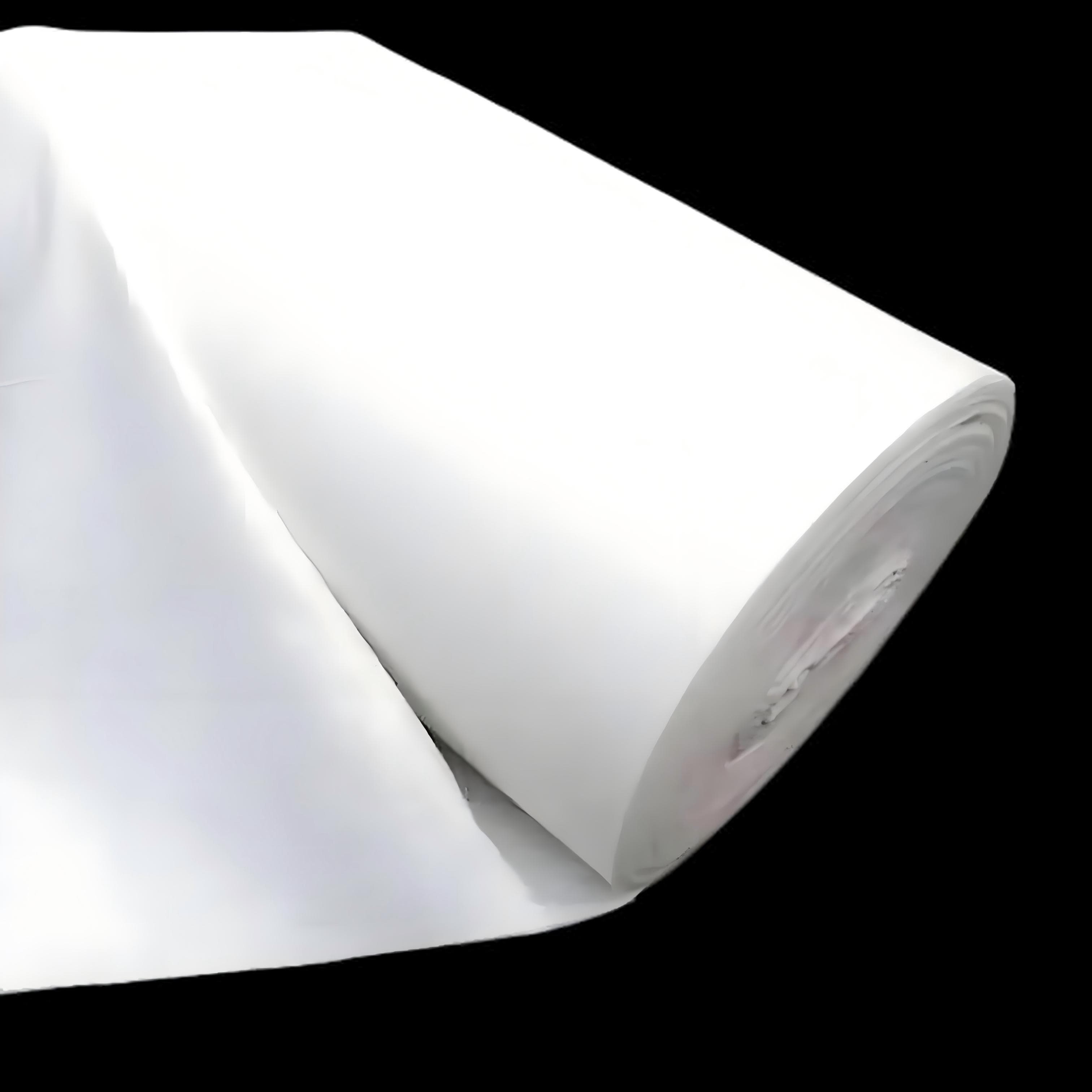

Geotextile Fabric under Concrete

1. Outstanding Strength and Stability: Utilizing a continuous filament yarn process, it boasts high tensile strength and can withstand engineering loads and deformation. The uniform fiber arrangement and robust structure ensure stable performance over long-term use.

2. Strong Weather and Corrosion Resistance: Resistant to high temperatures and UV rays, it resists damage during long-term outdoor use. Acid, alkali, and chemical corrosion resistance make it suitable for harsh working conditions such as landfills.

3. Multifunctional and Practical: It combines multiple functions, including isolation, filtration, and drainage, to trap soil particles and drain accumulated water. It enhances soil stability, prevents soil erosion, and is suitable for a variety of applications, including water conservancy projects and road construction.

4. Excellent Construction and Environmental Performance: Lightweight, highly flexible, and adaptable to cutting and splicing, its extra-wide width makes it easier to install. Contains no chemical additives, is non-toxic, and is an environmentally friendly engineering material.

Product Introduction:

Geotextile Fabric under Concrete is a new type of geosynthetic material for engineering applications, made from high-molecular-weight polymers through advanced processes such as spinning, needle punching, and thermal bonding. Made primarily from high-strength polypropylene or polyester, continuous filament spinning creates a uniform fiber network structure, allowing for flexible customization based on project requirements. This product combines excellent physical and mechanical properties with chemical stability, boasting exceptional tear and puncture resistance. It maintains stable performance in both high and low temperature ranges, exhibits excellent resistance to acidic and alkaline solutions, microorganisms, and UV rays, and is resistant to aging and degradation during long-term underground or exposed use.

In engineering applications, Filament Geotextile can simultaneously perform its five core functions: separation, filtration, drainage, reinforcement, and protection. For example, in highway subgrade construction, it can effectively isolate soil layers of different particle sizes to prevent particle mixing and subgrade subsidence. In water conservancy dam projects, its precise pore structure can intercept fine soil particles while rapidly draining seepage water, reducing the pore water pressure in the dam body. Filament Geotextile is also widely used in scenarios such as landfill anti-seepage layer protection, railway track base reinforcement, and slope ecological protection, providing key support for the stability and durability of engineering structures.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

Filament Geotextile, thanks to its versatility and stability, has found widespread and critical applications across a variety of engineering fields, including the following:

In highway and railway projects, it is a crucial auxiliary material for roadbed construction. When laid between the roadbed filler and the subgrade soil, it effectively separates the soil layers, preventing the mixing of particles of varying sizes that could cause deformation of the roadbed structure. Its excellent permeability also allows for rapid drainage of accumulated water within the roadbed, reducing erosion and enhancing its overall bearing capacity and stability, extending the service life of the road. When laid in the track base, it also acts as a buffer, reducing the impact of train traffic on the track structure.

Water conservancy and hydropower projects are another core application area. During dam construction, it is applied outside the dam's anti-seepage layer or between layers of fill. It not only traps fine soil particles, preventing seepage damage such as piping, but also drains excess water from within the dam, reducing pore water pressure and enhancing its anti-sliding stability. In river regulation and channel lining projects, it can be applied to river slopes or channel bottoms to protect the slope soil from erosion, reduce channel leakage, and improve water resource utilization efficiency.

Among environmental protection projects, landfill construction has a significant demand for Filament Geotextile. It is used as a protective layer in landfill anti-seepage systems, applied above and below the HDPE membrane. The upper layer prevents sharp objects in the landfill from piercing the membrane, while the lower layer prevents soil particles from damaging the membrane. It also guides the orderly discharge of landfill leachate, preventing it from contaminating the surrounding soil and groundwater. At sewage treatment plant sludge dumps, this product can also be applied to isolate sludge from the soil, reducing secondary pollution. In addition, in construction and municipal engineering, it can be used for the drainage layer of greening projects such as underground garage roofs and roof gardens. It works together with drainage boards to quickly drain the accumulated water in the greening soil layer and protect the building structure. In soft soil foundation treatment projects, it can be used in combination with geogrids and other materials to enhance the overall stiffness of the foundation, accelerate foundation consolidation and settlement, improve the foundation bearing capacity, and provide a stable foundation for upper building construction.

Filament Geotextile is widely used in various engineering fields due to its versatility and stability. In highway and railway projects, it is used for roadbed soil separation, drainage and erosion prevention, and track buffering. In water conservancy and hydropower projects, it helps prevent seepage and skid in embankments and protect rivers from soil leakage. In environmental protection projects, it acts as an anti-seepage membrane protective layer in landfills, guiding the discharge of leachate and isolating sludge from soil. In construction and municipal engineering, it can assist in drainage of greening projects and can be combined with other materials to enhance the stiffness of soft soil foundations.