Geocell Slope Protection: Key Specifications for Maximum Stability

Introduction: Why Specifications Matter for Geocell Slope Protection

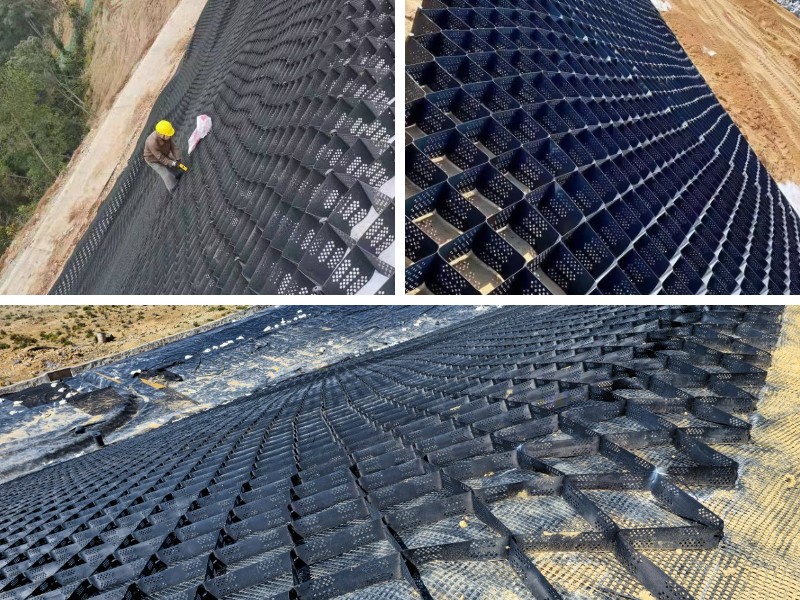

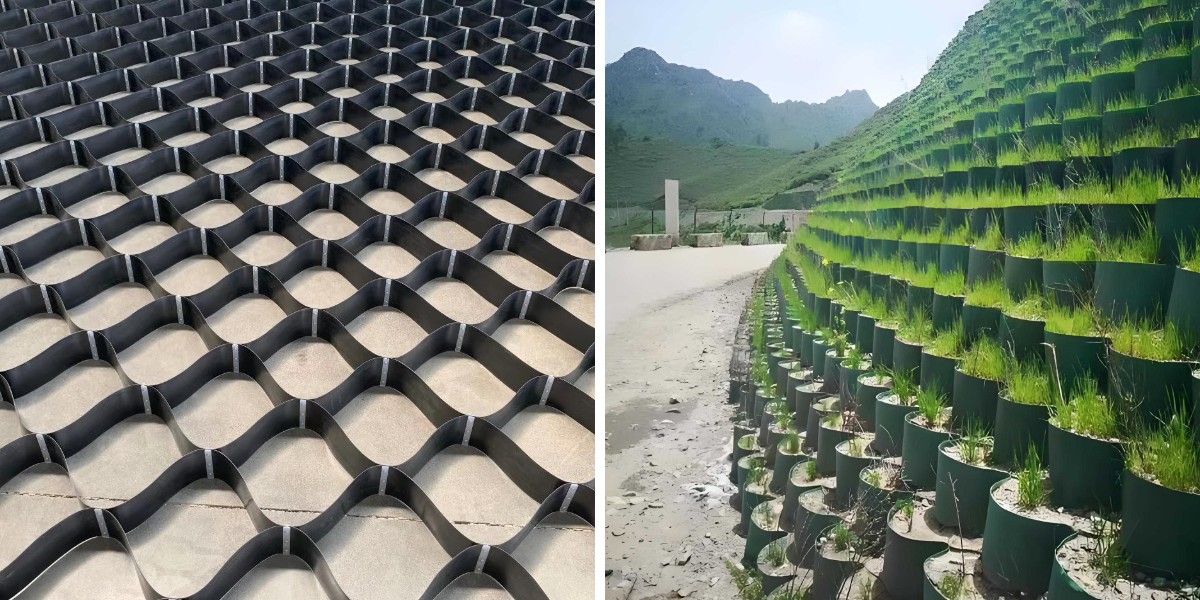

Geocell slope safety systems have revolutionized how we stabilize prone terrain, from highway embankments to mountainous slopes. These three-d honeycomb structures lock soil, aggregate, or vegetation in place, resisting erosion and landslides. However, their effectiveness hinges on key specifications—details like cloth strength, cell size, and thickness without delay impact stability. In this guide, we’ll destroy down the critical specs that make sure your geocell system gives you long-term slope protection.

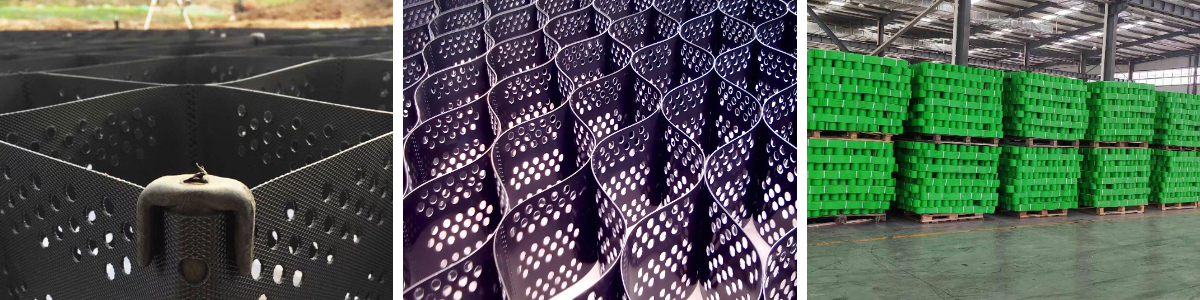

1. Geocell Material: The Foundation of Durability

The choice of geocell cloth determines resistance to environmental stress and load-bearing capacity:

HDPE Geocell(https://www.cggeosynthetics.com/hdpe-geocell/): High-density polyethylene (HDPE) is the industry standard. It gives exceptional tensile electricity (10-20 kN/m), UV resistance, and flexibility—even in extreme temperatures (-40°C to 60°C). HDPE geocell is best for permanent tasks (20+ years) like road reduce slopes, as it withstands freeze-thaw cycles and chemical exposure from soil.

PP Geocell: Polypropylene geocells are lighter and more cost-effective but much less UV-stable, making them suitable for brief slopes (5-10 years) such as construction web site embankments.

Composite Materials: Some geocells blend HDPE with reinforcing fibers to increase puncture resistance, critical for slopes with rocky soil.

For most stability, prioritize HDPE geocell—its durability outperforms different materials in high-stress environments.

2. Cell Dimensions: Size and Shape for Slope Angles

Cell dimension (height, width, and depth) must in shape the slope’s steepness and soil type:

Height: Typically 5-30 cm. Steeper slopes (30°+) require taller cells (15-30 cm) to anchor deeper soil layers. Gentle slopes (10-20°) work with 5-10 cm cells, reducing fabric costs.

Width/Length: Standard cell dimensions vary from 20x20 cm to 60x60 cm. Larger cells (40x40 cm+) are better for holding aggregate or vegetation, whilst smaller cells (20x20 cm) excel at stabilizing fine-grained soils.

Aspect Ratio: The ratio of height to width (e.g., 1:2) influences load distribution. A 1:3 ratio balances flexibility and rigidity, ideal for slopes inclined to minor shifting.

Mismatched cell dimensions can lead to soil slippage—always align specs with slope attitude and soil particle size.

3. Tensile Strength and Modulus: Resisting Slope Movement

Tensile strength (resistance to stretching) and modulus (stiffness) are non-negotiable for steep slopes:

Tensile Strength: Minimum 10 kN/m for low-risk slopes; 15+ kN/m for high-risk areas (e.g., close to highways). HDPE geocell often exceeds 20 kN/m, withstanding lateral soil stress during heavy rain or earthquakes.

Secant Modulus: Measures rigidity—300-500 MPa is common for HDPE. Higher modulus (500+ MPa) prevents cell deformation underneath constant load, imperative for slopes with heavy vegetation or traffic vibration.

These specs make certain the geocell doesn’t stretch or collapse when the slope shifts.

4. UV Resistance and Chemical Compatibility

Slopes are uncovered to sunlight and soil chemicals, so resistance to degradation is key:

UV Stabilization: Look for HDPE geocell with 2-3% carbon black additive, which blocks UV rays. This extends lifespan from 5 years (unstable PP) to 25+ years in sunny climates.

Chemical Resistance: HDPE resists acids, alkalis, and natural compounds in soil, unlike PP, which can also degrade in industrial or agricultural slopes with fertilizer runoff.

For coastal slopes, choose HDPE geocell with saltwater resistance to keep away from corrosion.

5. Installation Compatibility: Matching Terrain and Fill Material

Specs must align with set up methods and fill type:

Fill Material:

Soil/vegetation: Use 10-15 cm cells with porous HDPE to enable root growth (paired with geoweb erosion manage mats for extra support).

Aggregate (gravel): Larger cells (20-30 cm) with greater tensile strength (15+ kN/m) stop rock displacement.

Slope Preparation: Rough, uneven slopes need bendy HDPE geocell (elongation rate 15-25%) to conform to terrain besides tearing.

Proper compatibility ensures the geocell integrates seamlessly with fill, minimizing installation errors.

6. Connection Strength: Keeping Panels Secure

Geocell panels are joined with clips or welds—weak connections spell failure:

Clip Strength: Metal or HDPE clips have to withstand 3-5 kN of pressure to resist panel separation at some point of soil compaction.

Welded Seams: For large slopes, heat-welded seams (tensile energy 80% of base material) offer most desirable durability over clips.

Weak connections create gaps the place soil can escape—prioritize specs that guarantee panel integrity.

7. Comparison: HDPE Geocell vs. Traditional Solutions

HDPE geocell outperforms picks like concrete net or rock gabions in key areas:

Lower weight (easier transport for remote slopes).

Flexibility to adapt to slope motion (reducing cracking).

Compatibility with vegetation (supporting eco-friendly erosion control).

When paired with geoweb erosion control systems, HDPE geocell creates a synergistic barrier that stabilizes slopes whilst promoting plant growth.

Conclusion: Prioritize These Specs for Stable Slopes

To make certain maximum stability, center of attention on:

HDPE geocell for durability and UV resistance.

Cell top (15-30 cm) for steep slopes; 5-10 cm for gentle terrain.

Tensile energy (15+ kN/m) and UV stabilization (25-year rating).

Compatibility with fill material and impervious connections.

By aligning these specifications with your slope’s special challenges—whether extreme weather, heavy loads, or vegetation needs—you’ll create a geocell(https://www.cggeosynthetics.com/hdpe-geocell/) gadget that stands the test of time.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province