Cost Analysis: Is HDPE Geomembrane a Budget-Friendly Option for Reservoirs?

When planning a reservoir project, selecting the proper waterproofing fabric is crucial—not solely for structural integrity however additionally for long-term price range management. Among the a range of selections available, HDPE geomembrane has won good sized attention. But is it honestly a reasonable choice? This article dives into a distinctive fee evaluation of the usage of HDPE geomembrane in reservoirs, exploring its preliminary expenses, set up costs, upkeep requirements, and long-term savings. We’ll additionally spotlight the position of lay geomembrane waterproofing techniques, hdpe geomembrana specifications, and geomembrana in hdpe purposes to assist you make an knowledgeable decision.

Understanding HDPE Geomembrane for Reservoirs

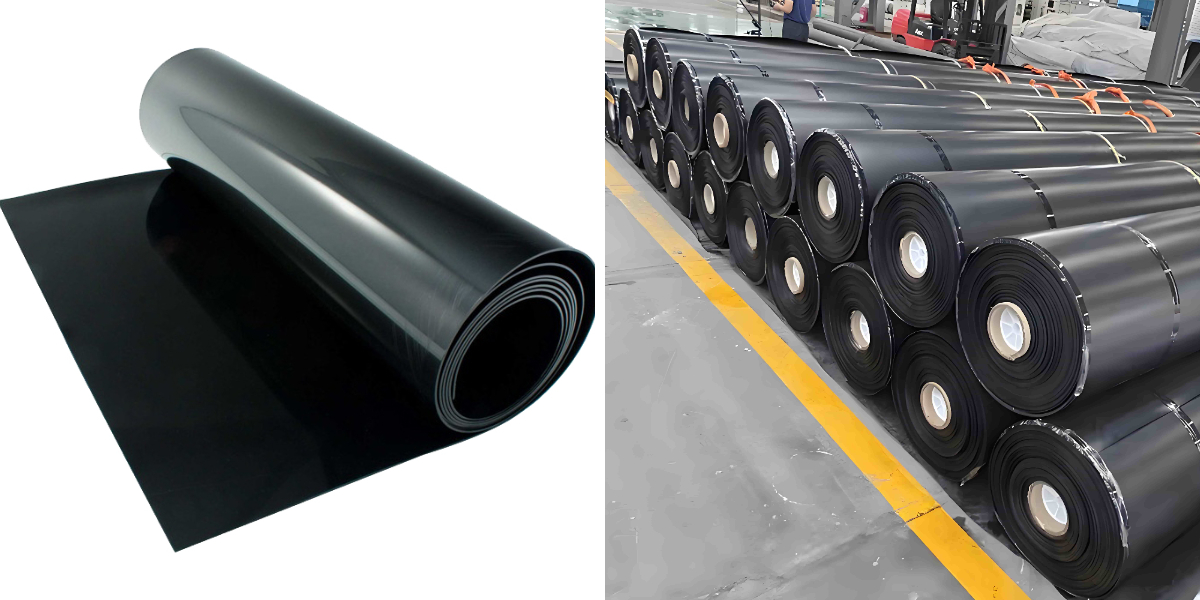

HDPE (High-Density Polyethylene) geomembrane is a artificial waterproofing fabric recognised for its durability, chemical resistance, and low permeability. Geomembrana in hdpe is engineered to create a dependable barrier towards water leakage, making it best for reservoirs, which require strict waterproofing to stop water loss and guard surrounding soil.

Hdpe geomembrana comes in a number thicknesses (typically 0.5mm to 3mm) and sizes, with rolls that can cowl massive areas—reducing the variety of seams at some point of installation. Its flexibility approves it to adapt to minor floor movements, whilst its UV resistance ensures toughness even in direct sunlight. These residences make it a robust candidate for reservoir projects, however how do they translate into costs?

Initial Material Costs: HDPE vs. Alternatives

The first step in value evaluation is evaluating the preliminary cloth costs of HDPE geomembrane with different waterproofing options, such as concrete, clay liners, or PVC geomembranes.

HDPE Geomembrane: The value of hdpe geomembrana levels from (1.50 to 3.50) per rectangular foot, relying on thickness and quality. Thicker sheets (2mm+) price greater however provide better puncture resistance—critical for reservoirs with rocky substrates.

Concrete Liners: Concrete can value (5 to 10) per rectangular foot, now not such as reinforcement or sealing agents. It’s susceptible to cracking over time, requiring widespread repairs.

Clay Liners: Clay is less expensive upfront (0.50 to 2) per rectangular foot) however requires particular compaction and can also fail in high-water-pressure environments, main to steeply-priced rework.

PVC Geomembranes: PVC charges (2 to 4) per rectangular foot, comparable to HDPE, however is much less UV-resistant and extra inclined to chemical degradation in agricultural reservoirs.

While geomembrana in hdpe isn’t the most inexpensive upfront, its stability of charge and overall performance offers it an facet over alternatives, specifically for large-scale reservoirs the place long-term reliability matters.

Installation Costs: Efficiency of lay geomembrane waterproofing

Installation charges play a good sized function in the whole task budget. lay geomembrane waterproofing for HDPE is fantastically straightforward, however suitable method is key to averting greater costs.

Labor Costs: Installing hdpe geomembrana requires skilled crews to unroll, seam, and anchor the sheets. Labor prices vary from (0.75 to 1.50) per rectangular foot, decrease than concrete (3 to 5) per rectangular foot) due to quicker installation. A 10-acre reservoir can be lined with HDPE in 2–3 weeks, in contrast to 4–6 weeks for concrete.

Seaming Technology: Heat fusion is the preferred approach for becoming a member of HDPE sheets, growing watertight seams that add (0.20 to 0.50) per rectangular foot. This is greater low cost than concrete’s joint-sealing costs, which frequently exceed $1 per rectangular foot.

Site Preparation: lay geomembrane waterproofing requires a smooth, debris-free base. While this provides \(0.50 to \)1 per rectangular foot for grading, it’s much less than the (2–3) per rectangular foot wished for clay compaction or concrete formwork.

Overall, HDPE set up expenses are 30–50% decrease than concrete, making it a budget-friendly preference for time-sensitive projects.

Long-Term Maintenance: Savings Over Time

A material’s real fee extends past installation—it consists of protection and restore prices over its lifespan. Geomembrana in hdpe excels here, thanks to its durability.

Lifespan: HDPE geomembrane lasts 20–30 years with minimal maintenance, outperforming PVC (10–15 years) and clay (10–20 years). Concrete liners frequently require foremost repairs after 10–15 years due to cracking.

Repair Costs: Minor punctures in hdpe geomembrana can be patched for \(5–\)10 per repair, whilst concrete cracks may additionally value \(50–\)100 per linear foot to fix. Clay liners regularly want re-compaction, costing \(1–\)2 per rectangular foot each 5–7 years.

UV and Chemical Resistance: HDPE’s resistance to daylight and agricultural chemical compounds (e.g., fertilizers) reduces the want for shielding coatings, saving \(0.10–\)0.30 per rectangular foot yearly in contrast to PVC, which requires UV stabilizers.

Over a 20-year lifespan, HDPE’s whole upkeep fees are 60–70% decrease than concrete and 40–50% decrease than PVC, offsetting any moderate upfront fee differences.

Water Loss Prevention: Hidden Savings

Reservoirs lose water via seepage, which interprets to economic losses—especially in arid areas or for irrigation reservoirs. Hdpe geomembrana minimizes this loss, supplying hidden price savings.

Seepage Rates: HDPE has a permeability charge of much less than 1x10^-12 cm/s, some distance decrease than clay (1x10^-7 cm/s) or concrete (1x10^-8 cm/s). A 10-acre reservoir with a clay liner can lose 50,000–100,000 gallons monthly, whilst an HDPE-lined reservoir loses much less than 1,000 gallons.

Water Replacement Costs: For agricultural reservoirs, changing misplaced water expenses \(0.005–\)0.01 per gallon. Over 20 years, an HDPE liner saves \(60,000–\)120,000 for a 10-acre mission in contrast to clay.

These financial savings by myself can justify selecting geomembrana in hdpe for water-strapped regions.

When Is HDPE Geomembrane Not the Best Budget Option?

While HDPE is comparatively cheap for most reservoirs, there are exceptions:

Small, Shallow Reservoirs: For ponds beneath 1 acre, clay liners can also be more cost-effective upfront, even though HDPE nonetheless gives higher long-term value.

Extreme Temperature Fluctuations: In areas with regularly occurring freeze-thaw cycles, thicker HDPE (2mm+) is needed, growing costs. However, its flexibility nonetheless makes it higher than inflexible concrete.

Temporary Projects: For reservoirs with a 5–10 12 months lifespan, PVC or transient clay liners may also be cheaper, however HDPE stays a safer guess for warding off early alternative costs.

Conclusion: HDPE Geomembrane—A Budget-Friendly Choice for Most Reservoirs

When factoring in preliminary fabric costs, set up efficiency, long-term maintenance, and water loss prevention, hdpe geomembrana emerges as a budget-friendly choice for most reservoir projects. Its stability of sturdiness and affordability, mixed with applicable lay geomembrane waterproofing techniques, ensures that geomembrana in hdpe can provide robust returns over its 20–30 yr lifespan.

For engineers, task managers, and finances planners, selecting HDPE capacity investing in a answer that minimizes upfront fees and avoids luxurious surprises down the line. Whether for municipal water storage, agricultural irrigation, or environmental reservoirs, HDPE geomembrane proves that first-rate and cost-effectiveness can go hand in hand.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province