Geotextile Fabric for Leach Field

1.Cost - Effective Solution

Reduces reliance on expensive materials like concrete and steel. It cuts down construction time and labor costs while maintaining project performance, offering a high cost - benefit ratio for large - scale civil engineering projects.

2.Excellent Durability

Resistant to UV radiation, chemical corrosion (acids, alkalis, and salts), and biological degradation (mold, bacteria, and rodent damage). It can maintain structural integrity for over 20 years in harsh outdoor environments.

3.High Permeability & Drainage

Its porous structure allows water and air to pass through freely, effectively draining excess groundwater from soil. This prevents soil saturation and reduces hydrostatic pressure on engineering structures.

4.Easy Installation & Handling

Lightweight, flexible, and available in large rolls, geotextile can be quickly cut, laid, and fixed on construction sites. It requires no special equipment, making it suitable for projects with tight schedules.

5.Environmentally Friendly

Made from recyclable polymer materials, it does not release toxic substances during use. It also helps with soil and water conservation, aligning with green construction standards.

Products Introduction:

Geotextile is a flexible, permeable polymer - based construction material made from polypropylene (PP), polyester (PET), or polyethylene (PE) fibers. It is manufactured through weaving, needle - punching, or heat - bonding processes, forming a stable, porous structure that bridges the gap between traditional civil engineering materials and modern geosynthetics. Widely used in infrastructure, environmental protection, and hydraulic engineering projects, geotextile acts as a multifunctional solution to enhance soil stability, improve drainage efficiency, and extend the service life of construction facilities.

Product Features:

1.Mechanical FeaturesHigh tensile strength, tear resistance, and puncture resistance; can withstand heavy loads and soil deformation without breaking.

2.Hydraulic FeaturesUniform pore size distribution, stable permeability coefficient, and good filtration performance; prevents soil particle loss while allowing water to flow.

3.Physical FeaturesLightweight (80–1000 g/m²), flexible, and resistant to high and low temperatures (-20℃ to 80℃).

4.Chemical FeaturesInert to most chemicals; suitable for use in coastal, industrial, and agricultural areas with complex soil conditions.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

Road & Railway Engineering

Placed between subgrade soil and pavement to separate different soil layers, prevent intermixing, and avoid pavement cracking or subsidence.

Used as a drainage layer in roadbeds to discharge groundwater and improve road stability.

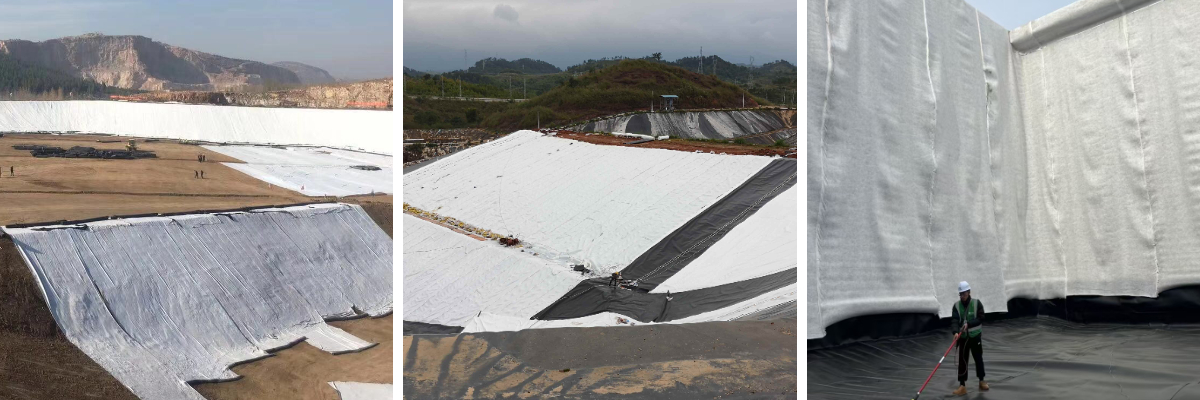

Hydraulic & Coastal Engineering

Lined in riverbanks, dams, and reservoirs for erosion control; prevents soil scouring by water flow.

Applied in coastal reclamation projects as a filter layer to protect dikes and seawalls.

Landfill & Environmental Engineering

Serves as a key component in landfill liners (combined with geomembranes) to filter leachate, prevent soil and groundwater contamination.

Used in sludge dewatering and wastewater treatment systems to separate solid and liquid phases.

Agricultural & Landscape Engineering

Laid under greenhouse soil or farmland to control root growth and prevent soil compaction.

Applied in slope greening projects to stabilize soil and assist vegetation growth.

Mining Engineering

Used in tailings dams and mine waste disposal sites to filter and drain, reducing the risk of dam failure.

Geotextile Fabric for Leach Field focuses on the special environment and core requirements of leachate sites, with the core advantages of "high-precision filtration to prevent clogging, strong corrosion resistance and degradation resistance, high strength adaptability to deformation, isolation and protection to protect the environment", providing reliable material support for leachate collection and treatment systems. Whether it is the large-scale application of landfills or high-risk scenarios in hazardous waste disposal centers, targeted performance design can balance the two goals of "system smoothness" and "environmental safety".

The product combines functionality and durability, which can reduce the maintenance cost of the leachate system and effectively prevent environmental pollution risks. It is a key material for achieving "safe disposal and green protection" in modern environmental engineering, providing important technical support for waste disposal and ecological environment protection.