Woven Geotextile for Soil Separation: Preventing Mixing in Subgrades

Introduction: The Hidden Cost of Subgrade Contamination

Beneath each and every secure road, railway, or paved place lies a foundational principle: the integrity of wonderful soil layers. The subgrade—the native soil formation—and the overlying mixture base direction ought to continue to be separate to function their special functions. When these layers mix, a cascade of geotechnical disasters begins. Fine subgrade soils infiltrate the coarse aggregate, robbing it of its drainage and load-bearing properties, whilst combination particles sink into the gentle subgrade, developing ruts and voids. This illness leads to untimely pavement failure, continual renovation issues, and substantially shortened infrastructure lifespan. The engineered answer to this pervasive trouble is the strategic set up of a separation geotextile, with Reinforced Machine Woven Fabric standing as the ultimate desire for demanding, high-load scenarios. This article important points how woven geotextiles hold layer integrity, at once contributing to the success of Road Construction Woven Geotextile initiatives and long lasting Slope Stabilization Woven Geotextile applications.

The Mechanism of Separation: How Woven Geotextiles Create a Stable Barrier

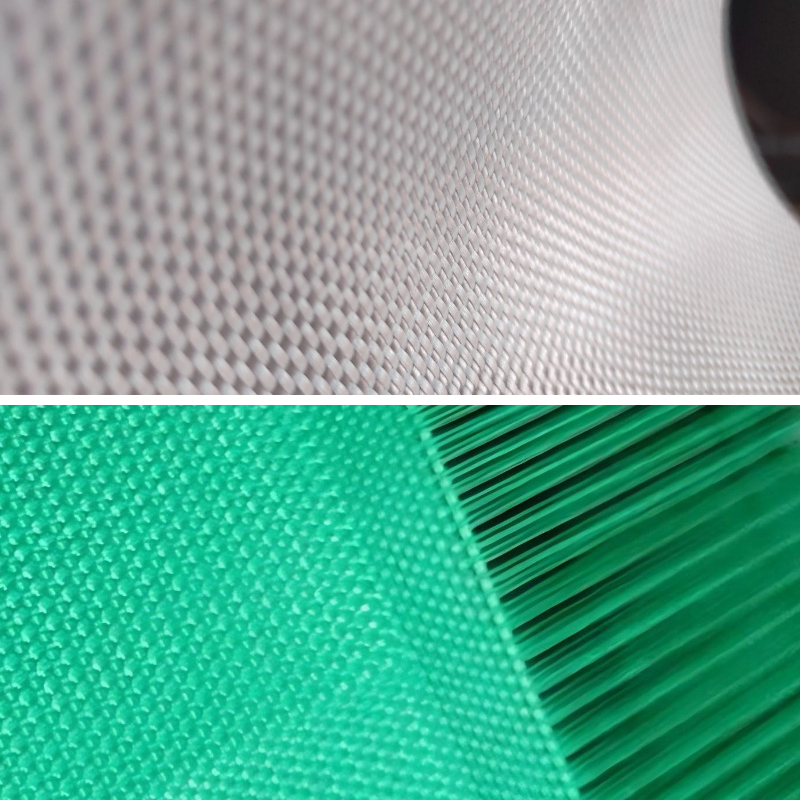

A woven geotextile is manufactured by using interlacing high-tenacity polypropylene or polyester yarns on industrial looms, developing a dimensionally secure material with excessive tensile strength. Its effectiveness as a separator stems from three concurrent mechanical actions:

Filtration and Soil Retention: The fabric's calibrated pore dimension (Apparent Opening Size) permits water to skip freely whilst bodily blockading the upward migration of quality soil particles into the combination layer. This prevents the "pumping" of fines below dynamic hundreds from traffic.

Tensile Reinforcement and Load Distribution: The excessive tensile power of a Reinforced Machine Woven Fabric allows it to face up to set up stresses and localized punctures. More importantly, it distributes wheel masses over a wider location of the subgrade. This "mattress effect" reduces factor stresses, stopping the mixture from being compelled down into the tender underlying soil.

Containment and Interface Stability: The cloth creates a permanent, easy boundary between the two layers. By confining the subgrade and encapsulating the aggregate, it keeps the diagram thickness and composition of the structural base course. This containment is equally necessary for Slope Stabilization Woven Geotextile systems, the place it prevents the erosion of fill material.

Critical Application: Road Construction Woven Geotextile

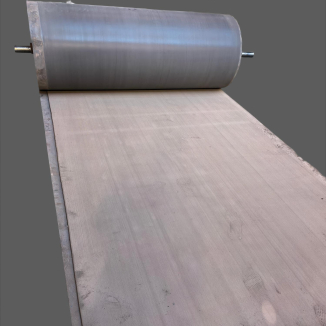

In Road Construction Woven Geotextile applications, the cloth is positioned at once on the organized subgrade earlier than the mixture base route is spread. Its position is foundational:

Preserving Base Course Integrity: It ensures the overwhelmed stone or gravel base stays free of fines, retaining its excessive permeability for drainage and its frictional residences for structural stability. This at once prevents rutting and pothole formation.

Reducing Aggregate Thickness: By stopping illness and subgrade weakening, the geotextile frequently permits for a reduction in the required depth of high-priced imported aggregate, main to vast fabric value savings.

Extending Service Life: A separated device dramatically reduces differential agreement and structural degradation, which interprets into fewer renovation cycles and a longer lifespan for the pavement. The use of a high-strength Reinforced Machine Woven Fabric is integral right here to live on the compaction and high-stress surroundings in the course of building and service.

Critical Application: Slope Stabilization Woven Geotextile

For Slope Stabilization Woven Geotextile projects, separation is a key characteristic inside a large reinforcement system. On slopes, the geotextile is established between distinct fill layers or between the fill and the native soil:

Preventing Internal Erosion: It stops finer soils from washing out via coarser drainage layers, which should in any other case lead to interior voids, piping, and eventual slope failure.

Creating a Stable Working Platform: During development of bolstered soil slopes, the material affords instantaneous separation, permitting for desirable compaction of fill layers and making sure the integrity of the strengthened zone.

Enhancing Composite Behavior: When used with geogrids or as the reinforcing aspect itself, the separation characteristic ensures that the reinforcing cloth interacts correctly with a clean, able fill material, maximizing the composite structure's strength.

Selection Criteria: Choosing the Right Woven Geotextile

Not all woven fabric are equal. Selecting the right Road Construction Woven Geotextile or Slope Stabilization Woven Geotextile requires evaluating key properties:

Tensile Strength and Modulus: The material ought to have excessive closing tensile electricity and low elongation (high modulus) to supply the crucial reinforcement and stability. This is the hallmark of a authentic Reinforced Machine Woven Fabric.

Puncture and Tear Resistance: It should continue to exist the placement and compaction of sharp combination besides damage.

Permittivity and AOS: The material should permit free water waft (high permittivity) whilst conserving soil particles (appropriate Apparent Opening Size). Clogging need to be avoided to make sure long-term drainage.

Durability: Resistance to UV degradation all through set up and long-term chemical/biological resistance in the soil are imperative for design-life performance.

Conclusion: An Investment in Long-Term Structural Integrity

The price of a woven geotextile separator is minimal in contrast to the long-term price of rehabilitating a failed subgrade. By putting in a sturdy Reinforced Machine Woven Fabric, engineers proactively forestall the mechanisms that lead to pavement misery and slope instability. It is a simple, single-layer answer that provides profound benefits: retaining cloth properties, decreasing lifecycle costs, and making sure the designed overall performance of the overlying structure.

Whether exact as a Road Construction Woven Geotextile for a motorway or as a Slope Stabilization Woven Geotextile for an embankment, its function is persistently critical. It is the unsung guardian of layer integrity, a testomony to the precept that in geotechnical engineering, now and again the most effective options are these that forestall issues from beginning in the first place. For any challenge constructed on granular fill over gentle subgrade, woven geotextile separation is no longer simply an option—it is a critical engineering necessity.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province