Why Is My HDPE Geomembrane Leaking? Troubleshooting Common Issues

HDPE geomembrane is a versatile, long lasting cloth extensively used in waterproofing initiatives throughout industries like waste management, agriculture, water conservation, and civil engineering. Its excessive chemical resistance, puncture strength, and flexibility make it a pinnacle preference for developing impermeable barriers. However, even the most dependable HDPE geomembrane can boost leaks, compromising the integrity of the whole system. Understanding the root motives of leaks is necessary to resolving problems correctly and defending your mission investment. Below, we destroy down the most frequent culprits at the back of HDPE geomembrane leaks and how to troubleshoot them effectively.

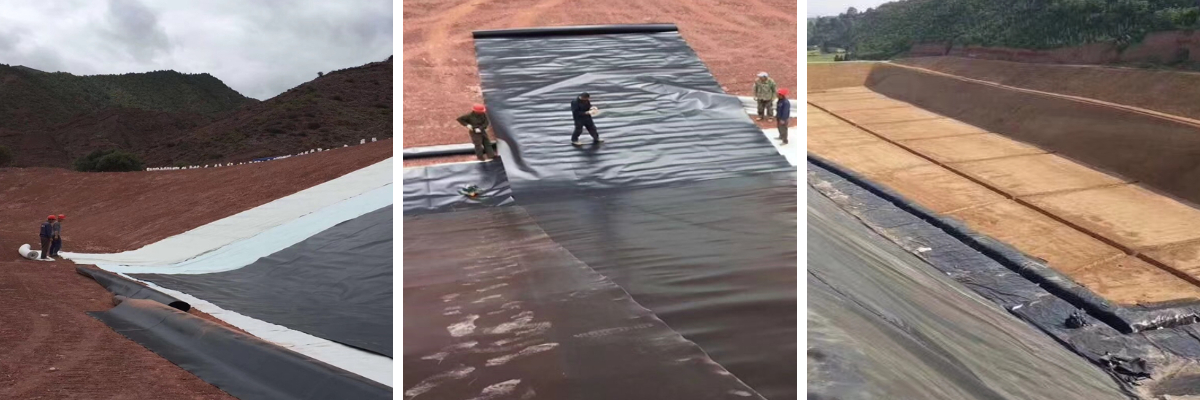

1. Improper Geomembrane Installation: The Leading Cause of Leaks

Most HDPE geomembrane leaks hint returned to improper geomembrane set up practices. Even splendid substances will fail if no longer mounted in accordance to enterprise standards. Installation blunders regularly show up due to insufficient training, rushed workflows, or brush aside for site-specific conditions, leading to vulnerable factors that enable water penetration over time.

1.1 Poor Seam Fusion or Bonding

Seams are the most prone section of any HDPE geomembrane system, as they join separate sheets of material. HDPE geomembrane seams are commonly joined the use of thermal fusion (hot wedge or extrusion welding) or chemical bonding, and each strategies require precision. If the welding temperature is too low, the fabric won’t fuse properly; if too high, it can degrade the HDPE, developing brittle seams. Additionally, soiled or damp seam surfaces stop applicable adhesion, leaving gaps for water to seep through.

To troubleshoot, habits non-destructive checking out (NDT) like air strain checking out or vacuum field checking out on all seams post-installation. Air stress checking out includes sealing a area of the seam and introducing air—if stress drops, a leak exists. For small leaks, re-weld the affected location after cleansing and drying the surface. For full-size seam failure, seek advice from a expert to do away with and re-install the frustrating section, making sure compliance with geomembrane waterproofing standards.

1.2 Inadequate Site Preparation Before Installation

Geomembrane set up requires a smooth, debris-free substrate to keep away from punctures and uneven stress. Rocks, roots, sharp gravel, or uneven terrain can pierce the HDPE geomembrane at some stage in set up or after the machine is loaded. Even small particles left below the membrane can create stress points, main to gradual put on and leaks.

Before putting in HDPE geomembrane, clear the web site of all sharp objects and stage the substrate. Use a geotextile underlayment to add an greater layer of safety towards punctures. If leaks are suspected due to negative web site prep, investigate the membrane for seen punctures—small holes can be patched with HDPE restore patches, whilst large harm can also require reducing out the affected location and putting in a new panel with desirable seam welding.

2. Material Defects and Degradation Over Time

While HDPE geomembrane is quite durable, cloth defects or environmental degradation can lead to leaks. These troubles might also no longer show up right away however can irritate over months or years, mainly in harsh conditions.

2.1 Manufacturing Defects

Rarely, HDPE geomembrane may additionally have inherent manufacturing defects, such as skinny spots, pinholes, or inconsistent thickness. These defects are regularly undetectable at some stage in visible inspection and can solely be recognized thru great manage trying out earlier than installation. Using low-quality or non-certified HDPE geomembrane will increase the threat of such defects, as producers may additionally reduce corners on uncooked substances or manufacturing processes.

To mitigate this, usually supply HDPE geomembrane from respectable suppliers with third-party certification. Conduct pre-installation inspections, which include thickness assessments and visible scans for pinholes. If a leak is traced to a manufacturing defect, contact the dealer for alternative and make sure the new cloth undergoes rigorous checking out earlier than geomembrane installation.

2.2 Environmental and Chemical Degradation

HDPE geomembrane is resistant to most chemicals, however extended publicity to intense temperatures, UV radiation, or harsh elements can degrade the material. UV rays, for example, can damage down the polymer shape over time, making the membrane brittle and susceptible to cracking. In industrial applications, publicity to focused acids, bases, or natural solvents might also additionally weaken the HDPE, main to leaks.

For outside projects, use UV-stabilized HDPE geomembrane and cowl the membrane with a protecting layer (e.g., soil, geotextile) to defend it from sunlight. In chemical applications, make certain the HDPE geomembrane is well matched with the resources being contained—consult a fabric professional to choose the proper grade. If degradation is detected, change the affected sections and replace the geomembrane waterproofing machine to higher face up to environmental stressors.

3. Mechanical Damage and Improper Maintenance

Mechanical injury to HDPE geomembrane can show up throughout installation, post-installation activities, or due to lack of maintenance. Even minor harm can enhance into great leaks if left unaddressed.

3.1 Punctures and Tears from Machinery or Foot Traffic

During geomembrane installation, heavy equipment (e.g., excavators, trucks) can by accident puncture the membrane if now not operated carefully. Post-installation, foot traffic, building of secondary structures, or even animal recreation can purpose tears. These damages are regularly seen however may additionally be left out in large-scale projects, particularly in hard-to-reach areas.

To stop mechanical damage, avoid get admission to to the HDPE geomembrane floor after installation—use walkways or protecting mats for critical foot traffic. Conduct normal inspections the usage of infrared cameras or leak detection structures to perceive hidden punctures. Small tears (less than five cm) can be repaired with HDPE patches, whilst large tears require changing the broken panel and re-welding seams. Always make certain repairs are like minded with the current geomembrane waterproofing system.

3.2 Neglecting Routine Maintenance

HDPE geomembrane structures require everyday upkeep to notice and get to the bottom of minor troubles earlier than they turn out to be predominant leaks. Neglecting inspections, permitting particles to accumulate, or ignoring symptoms of put on (e.g., cracking, peeling seams) can lead to machine failure. In initiatives like landfills or ponds, sediment buildup can disguise leaks, making them tougher to notice till water loss will become significant.

Establish a movements protection schedule: investigate the HDPE geomembrane quarterly for seen damage, smooth particles from the surface, and take a look at seams yearly the usage of NDT methods. For submerged systems, use leak detection sensors to reveal water degrees and perceive anomalies. Promptly tackle any problems found—delayed repairs can end result in high priced water loss, environmental damage, and the want for full gadget replacement.

Conclusion: Preventative Measures for Long-Term Performance

Leaks in HDPE geomembrane structures are regularly avoidable with desirable planning, expert geomembrane installation, and everyday maintenance. By addressing set up errors, choosing exceptional materials, and defending in opposition to environmental and mechanical damage, you can make certain the durability of your geomembrane waterproofing system. When leaks do occur, immediate troubleshooting the use of industry-standard checking out strategies will reduce downtime and restore costs.

Remember, investing in licensed materials, educated installers, and activities inspections is a long way extra most economical than addressing leaks after they’ve compromised your project. For complicated problems or large-scale systems, seek advice from a geomembrane expert to make sure correct prognosis and wonderful repairs.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province