Why Geocell is More Cost-Effective Than Traditional Methods

In current years, geocell has emerged as a famous preference in a extensive vary of development and civil engineering projects. This modern geosynthetic material, frequently made from excessive - density polyethylene (HDPE) in the shape of geocell HDPE, is a three - dimensional honeycomb - like structure. It has discovered its way into tasks such as avenue development (geocell road), slope stabilization, and erosion control. For instance, in areas with difficult terrains or vulnerable soil conditions, geocell has established to be an nice solution, which has led to its growing adoption throughout the globe.

Purpose of the Article

The intention of this article is to behavior a complete assessment between geocell and common strategies used in comparable engineering applications. By inspecting elements such as initial investment, lengthy - time period preservation costs, and overall performance efficiency, we will absolutely reveal why geocell is a extra fee - fine option. Whether you are a venture manager, an engineer, or a development enthusiast, appreciation the fee - effectiveness of geocell can assist you make greater knowledgeable selections for future projects.

What is Geocell?

Definition and Structure

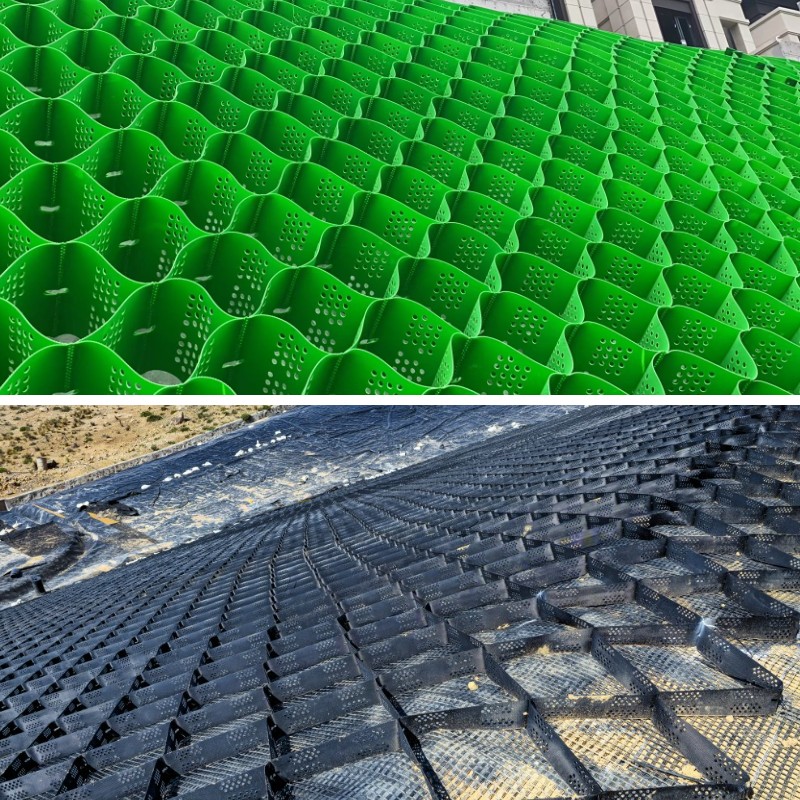

Geocell, quick for geosynthetic cell confinement system, is a progressive geosynthetic material. It is made up of excessive - electricity sheet substances that are joined collectively thru methods like ultrasonic welding to structure a three - dimensional honeycomb - like structure. This special honeycomb graph is the key to its great performance. Each cellphone in the geocell shape is interconnected, growing a community that can successfully confine and stabilize the substances positioned inside it.

For example, assume of it as a honeycomb - like framework. When stuffed with soil, gravel, or different materials, the geocell fabric, which types the partitions of the cells, restricts the lateral motion of these fill materials. This consequences in a extra steady and load - bearing composite structure. In a geocell avenue project, the geocell's shape helps to distribute the load of site visitors evenly throughout the underlying soil, lowering the chance of agreement and enhancing the ordinary sturdiness of the road.

Materials Used (Highlight HDPE)

Geocells are commonly manufactured from a range of materials, with excessive - density polyethylene (HDPE) being one of the most famous choices. HDPE is a thermoplastic polymer acknowledged for its remarkable bodily properties. It has a excessive energy - to - weight ratio, which potential that geocells made from HDPE can face up to great hundreds whilst last enormously lightweight. This makes them convenient to transport and install, decreasing labor prices at some point of construction.

HDPE geocells additionally showcase great resistance to abrasion and chemical corrosion. Whether it is in contact with acidic or alkaline soils, or in harsh environmental conditions, HDPE - made geocell hdpe can preserve its integrity over lengthy periods. This sturdiness is fundamental for purposes such as geocell avenue construction, the place the geocell will be exposed to regular visitors loads, weathering, and workable chemical contaminants from automobile emissions. Additionally, HDPE is resistant to ultraviolet (UV) radiation, making sure that the geocell does now not degrade when uncovered to daylight throughout its provider life.

Geocell in Road Construction (Geocell Road)

Traditional Road Construction Methods and Their Costs

Traditional street building strategies normally depend on substances like sand, gravel, and cement. The procurement of these substances can be costly. For example, excessive - first-class gravel wishes to be quarried, which includes extraction costs, and then transported to the building site. The transportation costs can add considerably to the usual cost, specially if the quarry is a long way from the venture location.

Cement manufacturing is strength - intensive, and its fee is additionally influenced with the aid of elements such as uncooked cloth prices and market demand. In the building process, a massive quantity of these substances is required. For a popular - sized street project, heaps of sand, gravel, and cement are needed. Additionally, labor prices for usual street building are high. Workers are wanted for duties such as excavating the foundation, laying the base layers, and pouring the cement or asphalt. Specialized gear like bulldozers, graders, and concrete mixers are additionally essential, and their condo or buy costs, alongside with gasoline consumption and maintenance, make a contribution to the standard expense.

How Geocell Improves Road Construction Economically

Geocell provides various monetary benefits in street construction. First, it appreciably enhances soil stability. When used in a geocell avenue project, the geocell confines the soil inside its cells, decreasing the chance of soil displacement underneath visitors loads. This capability that the street can stand up to heavy site visitors barring the want for immoderate base layers. As a result, the quantity of common fill substances like gravel and sand can be reduced.

The set up of geocell is enormously straightforward. It can be without problems unrolled and anchored in place, which reduces the want for a giant wide variety of distinctly - professional workers. This cuts down on labor costs. The building time is additionally shortened in contrast to normal methods. For instance, in some small - scale avenue restore projects, the usage of geocell can whole the work in a fraction of the time it would take with regular reconstruction methods. This no longer solely saves labor hours however additionally approves the street to be opened to site visitors sooner, minimizing disruptions to transportation and probably producing monetary advantages earlier.

Cost Comparison Examples

Let's reflect onconsideration on a hypothetical avenue development project. For a 1 - kilometer long, 6 - meter broad avenue with a diagram lifestyles of 20 years. Using normal methods, the price breakdown may be as follows: cloth charges for gravel, sand, and cement ought to quantity to \(200,000, labor prices for development over a length of three months should be \)100,000, and tools charges (including condo and fuel) should be \(50,000. So the preliminary development fee is \)350,000. Over the 20 - yr lifespan, the estimated preservation cost, which include periodic resurfacing and patching due to put on and tear, is around \(150,000. So the complete value over 20 years is \)500,000.

Now, if we use geocell in the identical project. The value of geocell hdpe fabric would possibly be \(120,000. Since geocell simplifies the building process, labor prices should be decreased to \)60,000, and gear expenses to \(30,000, ensuing in an preliminary development price of \)210,000. Due to the more suitable sturdiness supplied via geocell, the upkeep price over 20 years is estimated to be solely \(50,000. So the complete fee over 20 years is \)260,000. This instance definitely suggests that the use of geocell can lead to sizeable fee financial savings in avenue development projects.

The Role of Geocell Fabric

Understanding Geocell Fabric

Geocell material is an fundamental section of the geocell structure. It is generally made from materials such as excessive - density polyethylene (HDPE), polypropylene (PP), or polyester. The cloth varieties the walls of the geocell's honeycomb - like cells. It has countless key traits that make contributions to the normal overall performance of the geocell system.

Firstly, geocell material has excessive strength. This energy approves it to face up to the lateral stress exerted by way of the fill substances inside the cells and the exterior masses utilized to the geocell structure. For example, in a geocell - stabilized slope, the cloth ought to be sturdy ample to maintain the soil in place, stopping it from sliding down the slope due to gravitational forces.

Secondly, it has desirable water permeability. This property is indispensable as it permits the drainage of water thru the geocell system. In avenue development (geocell road), for instance, water can freely omit thru the geocell fabric, lowering the danger of waterlogging and the related injury to the avenue structure. Waterlogging can weaken the soil below the road, main to contract and cracking. The permeability of the geocell cloth helps to hold the balance of the street by means of permitting water to escape.

Moreover, geocell material serves more than one features such as separation, reinforcement, and protection. As a separator, it prevents the mixing of one of a kind soil layers or fill materials, making sure that every layer performs its supposed function. In reinforcement, it presents extra electricity to the soil or fill materials, bettering the universal load - bearing potential of the structure. And as a protector, it shields the underlying soil from erosion, chemical attacks, and mechanical damage.

Cost - saving Aspects in Applications

In quite a number applications, geocell cloth performs a full-size position in price - savings. In erosion manage projects, the geocell fabric, alongside with the geocell structure, correctly reduces soil erosion. By confining the soil inside the cells, it minimizes the loss of soil due to water and wind erosion. This skill that there is no want for universal re - grading or alternative of eroded soil, which saves each cloth and labor expenses over time.

In avenue building (geocell road), the geocell material contributes to fee - financial savings in countless ways. Since it improves the balance of the avenue base, it reduces the frequency of maintenance. For example, the want for normal patching and resurfacing is reduced due to the fact the geocell - strengthened street can higher face up to the stresses from traffic. The lengthy - time period value of retaining a geocell - based totally avenue is an awful lot decrease in contrast to a usual avenue barring geocell reinforcement. Additionally, in initiatives the place the soil stipulations are poor, geocell material can be used to enhance the soil's properties, disposing of the want to import giant quantities of excessive - great fill substances from far-off sources, which cuts down on transportation and fabric procurement costs.

Advantages of HDPE Geocell (Geocell HDPE)

Superior Physical Properties of HDPE Geocell

HDPE geocell (geocell HDPE) stands out due to its magnificent bodily properties. Its excessive tensile energy allows it to endure heavy hundreds except considerable deformation. In a geocell avenue application, the excessive tensile power of HDPE geocell ensures that it can cope with the non-stop stress from traffic. For example, in areas with a excessive extent of heavy - responsibility trucks, the geocell HDPE can keep its structural integrity, stopping the street from cracking or collapsing underneath the weight.

The resistance of HDPE geocell to chemical corrosion is any other incredible feature. In industrial areas the place the soil can also be contaminated with chemical substances from industrial waste, HDPE - made geocells can guard the underlying soil and avenue shape from the corrosive results of these chemicals. Whether it is publicity to acidic materials from battery leaks or alkaline runoff from positive manufacturing processes, the geocell hdpe stays stable, making sure the lengthy - time period overall performance of the infrastructure.

Moreover, HDPE geocell has wonderful climate resistance. It can undergo severe temperature variations, from the sweltering warmth of deserts to the freezing bloodless of polar regions. UV - resistant HDPE ensures that the geocell does no longer degrade when uncovered to daylight for prolonged periods. This climate resistance is integral for functions such as slope stabilization, the place the geocell can also be wholly uncovered to the factors for years.

Long - time period Cost - effectiveness

These brilliant bodily residences of HDPE geocell translate into lengthy - time period value - effectiveness. The excessive tensile power and sturdiness suggest that the geocell requires fewer replacements over its lifespan. In a normal avenue construction, substances may also want to be changed each and every few years due to put on and tear. However, with geocell HDPE in a geocell street project, the street can remaining lots longer, decreasing the frequency of highly-priced reconstruction projects.

The resistance to chemical corrosion and weathering additionally contributes to fee - savings. Since the geocell is much less possibly to be broken by way of chemical contaminants or harsh climate conditions, the renovation charges related with defending the avenue or shape from these elements are substantially reduced. For instance, there is no want to usually practice chemical - resistant coatings or operate emergency repairs due to climate - brought about damage. This effects in a decrease standard fee of ownership, making HDPE geocell a extra price - fine preference in the lengthy run, specially for tasks with a lengthy format existence and in difficult environmental conditions.

Installation and Maintenance Cost Comparison

Easier Installation of Geocell

The set up manner of geocell is a principal issue contributing to its fee - effectiveness. Geocell, whether or not it is made of geocell HDPE or different materials, is designed for simplicity in installation. It can be without problems unrolled and laid out on the organized surface. For example, in a geocell street building project, the geocell can be shortly placed alongside the roadbed, and then stuffed with the fantastic fill substances such as soil or gravel.

Compared to standard methods, geocell requires fewer specialised skills. Workers with simple building understanding can be educated to set up geocell in a quick time. In contrast, common street development or different engineering techniques frequently demand exceptionally - knowledgeable employees for duties like unique concrete pouring or complicated soil compaction procedures. This distinction in ability necessities capacity that the labor price for geocell set up is typically lower.

Moreover, the set up of geocell generally requires much less equipment. There is no want for giant - scale and steeply-priced equipment such as heavy - responsibility concrete mixers or massive - tonnage bulldozers. Smaller tools like hand - held equipment for anchoring the geocell in vicinity and easy filling tools are commonly sufficient. This reduces gear condominium or buy costs, as properly as gasoline consumption and gear preservation expenses. Additionally, the simplified set up procedure of geocell drastically shortens the development period. In a busy city area, for instance, a avenue development assignment the use of geocell can be performed lots faster, minimizing visitors disruptions and the related monetary losses precipitated by using site visitors congestion.

Lower Maintenance Requirements

Geocell's shape and the substances used, such as geocell material and geocell HDPE, endow it with low preservation requirements, which is any other factor of its value - effectiveness. The honeycomb - like shape of geocell efficaciously distributes loads, decreasing the stress attention on any single phase of the structure. In a geocell - strengthened road, this capability that the street floor is much less in all likelihood to enhance cracks or potholes over time due to visitors loads.

The excessive - fantastic substances of geocell, specifically HDPE, are resistant to more than a few environmental factors. They do now not corrode without difficulty in the presence of moisture, chemical substances in the soil, or publicity to sunlight. This sturdiness ensures that the geocell continues its integrity and overall performance over a lengthy period. In contrast, regular development substances might also degrade extra unexpectedly below the identical environmental conditions. For example, common asphalt roads may also want to be resurfaced each and every few years due to put on and tear, oxidation, and the results of weather, whilst a geocell - primarily based avenue can hold its pleasant for a a whole lot longer time with solely minimal maintenance, such as occasional cleansing of the floor and inspection of the anchoring points.

Furthermore, in functions like slope stabilization, geocell's capacity to stop soil erosion reduces the want for conventional re - grading and soil replacement. Once installed, the geocell cloth holds the soil in place, defending it from the erosive forces of water and wind. This lengthy - term balance consequences in substantial price financial savings over the existence cycle of the project, as the charges related with repeated protection and restore work are significantly reduced.

Environmental Benefits and Indirect Cost Savings

Reduced Material Consumption

One of the enormous environmental advantages of geocell is its decreased fabric consumption. In normal building methods, giant portions of substances like sand, gravel, and cement are required. For example, in avenue construction, a giant quantity of gravel is used to construct the base layers. However, when the use of geocell in a geocell street project, the quantity of these typical substances can be extensively reduced.

The geocell's shape efficiently confines and stabilizes the soil, permitting for a thinner layer of fill materials. This now not solely cuts down on the direct price of buying and transporting these substances however additionally reduces the environmental fee related with their extraction. Mining sand and gravel can lead to habitat destruction, soil erosion, and disruption of water systems. By the usage of less of these substances in construction, geocell helps to mitigate these terrible environmental impacts, making it a extra sustainable and fee - high-quality alternative in the lengthy run.

Long - time period Sustainability and Cost

Geocell - primarily based tasks provide lengthy - time period sustainability, which in flip leads to fee savings. In the case of a geocell - strengthened avenue (geocell road), its more suitable sturdiness skill that it requires fewer repairs and reconstructions over time. Traditional roads frequently want to be resurfaced or even totally rebuilt due to put on and tear, site visitors loads, and environmental factors. These repeated restore and reconstruction initiatives are now not solely highly-priced in phrases of substances and labor however additionally purpose disruptions to visitors and monetary activities.

For example, a standard street in an region with heavy site visitors might also want to be resurfaced each and every 5 - 7 years. Each resurfacing venture includes the use of substances such as asphalt, tools like pavers, and a large quantity of labor. In contrast, a geocell - based totally avenue can preserve its integrity for 15 - 20 years with solely minor maintenance. This lengthy - time period sustainability reduces the standard price of avenue ownership, along with each direct building and upkeep expenses as properly as oblique fees such as the financial losses brought on by way of site visitors disruptions at some stage in avenue repairs. In addition, the decreased want for widespread avenue work additionally skill much less power consumption and fewer emissions related with development equipment, similarly contributing to its environmental and value - effectiveness advantages.

Conclusion

Recap of Key Points

Throughout this article, we have explored the a variety of components that make geocell a extra price - wonderful choice in contrast to ordinary methods. In phrases of materials, geocell, specifically geocell HDPE, gives most excellent bodily houses such as excessive tensile strength, chemical corrosion resistance, and climate resistance. These homes make certain its lengthy - time period durability, decreasing the want for widespread replacements.

In avenue development (geocell road), geocell simplifies the development process, reduces the demand for usual fill materials, and shortens the building time. The set up of geocell is less complicated and requires much less specialised labor and equipment, which leads to sizeable fee financial savings in both the quick and lengthy term. Geocell fabric, an quintessential section of the geocell structure, contributes to value - financial savings thru features like separation, reinforcement, and protection, and via decreasing protection desires in purposes such as avenue building and erosion control.

Moreover, geocell's environmental benefits, consisting of decreased cloth consumption and lengthy - time period sustainability, translate into oblique price savings. The decrease upkeep necessities of geocell - primarily based tasks in addition beautify its price - effectiveness over the existence cycle of the infrastructure.

Encouragement for Further Adoption

Given the severa value - positive benefits of geocell, it is fairly encouraged that engineers, venture managers, and development authorities reflect onconsideration on geocell for a large vary of infrastructure projects. Whether it is constructing new roads, stabilizing slopes, or controlling erosion, geocell can furnish a greater environment friendly and sustainable solution. By deciding on geocell, no longer solely can we obtain considerable fee savings, however we can additionally make a contribution to greater environmentally pleasant building practices, main to a win - win state of affairs for each the economic system and the environment. As the development enterprise continues to evolve, geocell is set to play an an increasing number of necessary position in shaping the future of infrastructure development.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province