What to Look for When Buying Cement Blanket: Quality, Durability & Manufacturer Certifications

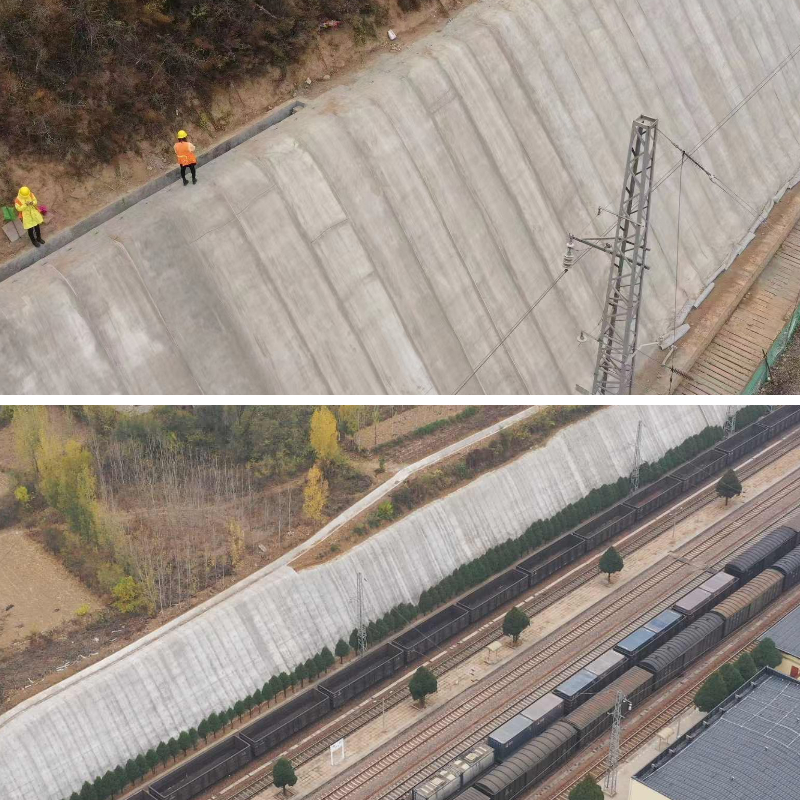

In construction, slope protection, and emergency restore projects, cement blanket (also acknowledged as cement canvas) has come to be a game-changer—offering speedy installation, excessive strength, and superb erosion resistance. However, low-quality cement blanket can lead to cracking, inadequate strength, and challenge failure, costing you time and money. As a buyer, understanding what to consider is indispensable to making a clever investment. This information breaks down 4 fundamental elements to consider, assisting you perceive high-performance cement blanket that meets your task needs.

1. Evaluate Core Quality Indicators: The Foundation of Reliable Cement Blanket

Quality is the cornerstone of any cement blanket—only merchandise with steady core warning signs can supply predicted performance. Focus on three non-negotiable metrics to examine excellent comprehensively:

1.1 Compressive Strength After Curing

Compressive electricity is the most fundamental indicator of a cement blanket’s load-bearing capacity, at once figuring out its suitability for structural or protecting projects. To confirm this, request the manufacturer’s check reviews or behavior on-site sampling tests: after curing the cement blanket pattern at 20℃ and 90% humidity for 28 days, use a compression trying out computer to measure its compressive strength. Industrial requirements require a minimal of 30 MPa for conventional construction; for high-demand situations like avenue base reinforcement or holding wall construction, the energy need to attain forty MPa or higher. A electricity under 25 MPa suggests inferior cement mixture or incorrect fiber-cement ratio—avoid such merchandise as they are inclined to crushing below pressure.

1.2 Setting Time Control

The putting time of cement canvas at once impacts development effectivity and quality. Too quickly putting leaves no time for shaping or adjustment, whilst too sluggish placing prolongs the building duration and increases the danger of rain damage. Standard necessities specify an preliminary putting time of 45-90 minutes and a last placing time of 6-12 hours. To check this, location a 30cm×30cm cement blanket pattern in a general surroundings (20℃, 60% humidity) and document the time when it no longer sticks to the finger (initial setting) and when it can endure a 1kg weight except deformation (final setting). Reputable producers will modify the placing time with retarders or accelerators in accordance to mission needs—for emergency repairs, pick out fast-setting variations (final putting inside four hours); for large-area laying, choose for normal-setting types.

1.3 Fiber Bonding Strength

Cement blanket’s power and flexibility remember on the tight bonding between reinforcing fibers and cement matrix—poor bonding reasons fiber detachment and floor peeling. To examine this, function a easy peel test: after curing a pattern for 7 days, use pliers to pull the floor fibers gently. Qualified cement blanket will have fibers that are hard to pull out, and the peeled vicinity will exhibit cement adhering to the fiber surface. If fibers come off without difficulty or the peeled floor is smooth, it capability the fiber therapy is insufficient or the cement paste is of bad quality. For out of doors initiatives uncovered to temperature changes, this trouble will irritate over time, main to usual structural failure.

2. Assess Durability: Ensure Long-Term Performance in Harsh Environments

Cement blanket frequently serves in harsh conditions—exposed to rain, sunlight, and chemical erosion. Durability trying out ensures it keeps overall performance for 10-20 years. Focus on three key resistance properties:

2.1 Water Resistance and Impermeability

Water resistance is integral for tasks like pond liners, canal repair, or slope protection. To take a look at a cement blanket’s impermeability, observe the hydrostatic stress method: seal a cured pattern in a strain chamber, observe water stress steadily (starting from 0.1 MPa, growing by way of 0.05 MPa each and every 30 minutes), and display for water seepage. Qualified merchandise ought to stand up to 0.3 MPa for 24 hours except leakage. For initiatives in water-rich areas, request a take a look at at 1/2 MPa. Additionally, test for water absorption rate—after soaking a 24-hour cured pattern in water for forty eight hours, its weight achieve have to no longer exceed 8%; immoderate absorption leads to inside growth and cracking.

2.2 UV and Weathering Resistance

Outdoor cement canvas is inclined to brittleness and floor spalling due to long-term UV exposure. To consider UV resistance, use a xenon arc weatherometer to simulate one thousand hours of out of doors daylight (equivalent to 10 years of herbal exposure). After testing, the sample’s compressive electricity have to keep at least 80% of its unique value, and there need to be no apparent peeling or cracking on the surface. Reputable merchandise add UV stabilizers (such as titanium dioxide) throughout production—ask for a cloth composition file to verify this. For wilderness or high-altitude areas with sturdy UV radiation, pick out merchandise with better UV protection.

2.3 Chemical Corrosion Resistance

In industrial zones, agricultural areas, or coastal projects, cement blanket might also come into contact with acidic/alkaline elements or saltwater. Test chemical resistance through immersing cured samples in frequent corrosive options (10% sulfuric acid, 20% sodium chloride, or nearby groundwater) for 30 days. After immersion, the pattern need to exhibit no apparent discoloration, swelling, or weight loss (≤±5%), and its compressive electricity retention have to be ≥90%. For industrial waste therapy web sites or coastal reclamation projects, pick out cement blanket with specialised anti-corrosion components to keep away from untimely degradation.

3. Verify Manufacturer Certifications: Avoid Counterfeit and Substandard Products

Certifications are a direct reflection of a manufacturer’s professionalism and product compliance. Never buy cement blanket barring legitimate certifications—they make sure the product meets enterprise requirements and protection requirements. Focus on these key certifications:

3.1 International and National Quality Standards

Look for certifications that align with world or regional standards. Internationally, the ISO 9001 Quality Management System certification ensures constant manufacturing quality, whilst ISO 14001 Environmental Management System certification shows eco-friendly manufacturing processes. In particular regions, take a look at for neighborhood certifications: CE certification for the European market, ASTM D7580 certification (specific to cement canvas) in the U.S., and GB/T 35172-2017 certification in China. These certifications require rigorous product trying out and manufacturing facility audits—products except them are in all likelihood to be unqualified.

3.2 Specialized Application Certifications

For tasks with particular requirements, affirm specialised certifications. For example, slope safety initiatives require anti-erosion certification (such as the U.S. NRCS certification), whilst emergency flood manage initiatives want rapid-setting overall performance certification. For food-related initiatives (e.g., farm pond lining), make sure the cement blanket has food-grade protection certification to keep away from heavy steel leaching. Ask the producer to furnish unique certification archives (not simply copies) and confirm their validity thru reliable channels—counterfeit certifications are frequent in the low-end market.

3.3 After-Sales and Quality Guarantee Certificates

Reliable producers furnish best warranty certificates and after-sales provider commitments. The assurance duration ought to be at least five years, overlaying problems like power loss, cracking, or peeling induced by means of product defects. Additionally, test if the producer presents technical support—such as on-site set up education or customized product formulations for particular projects. Avoid producers that refuse to supply warranty certificates or solely provide temporary ensures (less than three years)—they regularly lack self belief in their product quality.

4. Check Construction Adaptability: Ensure Smooth On-Site Application

Even super cement blanket will fail if it’s incompatible with your development scenario. Evaluate building adaptability to keep away from on-site wastage and delays:

4.1 Flexibility and Shaping Performance

Cement blanket wishes to adapt to irregular surfaces (e.g., curved slopes, pipeline surroundings). Test flexibility via putting an uncured cement canvas pattern on a 30cm-diameter cylindrical mold—qualified merchandise need to wrap round the mildew besides cracking or folding. For initiatives with complicated shapes (e.g., tunnel lining), pick merchandise with excessive fiber content material (≥15%) as they provide higher flexibility. Avoid overly inflexible cement blanket, as it’s hard to form and inclined to cracking at bends.

4.2 Installation Efficiency and Compatibility

Consider the product’s weight, roll size, and set up requirements. Standard cement blanket rolls are 3m extensive and 10m long, weighing 20-30kg per rectangular meter—suitable for guide or mechanical laying. For high-altitude or narrow-space projects, pick light-weight editions (≤25kg/m²) for less difficult transportation. Additionally, take a look at compatibility with set up materials: if the usage of nails or anchors for fixing, make certain the cement blanket has ample tear resistance (≥5 kN/m) to keep away from injury throughout installation. Ask the producer for set up manuals and on-site coaching help if needed.

4.3 Storage and Transportation Stability

Cement blanket is touchy to moisture—poor storage leads to untimely curing. Check the manufacturer’s packaging: certified merchandise use moisture-proof plastic movie and water-proof woven bags, with a shelf existence of 6 months beneath dry conditions. During transportation, make certain the rolls are now not pressed or soaked in water. If the product arrives with damp packaging or hardening at the edges, it’s already broken and ought to be rejected. Reputable producers will furnish storage recommendations to prolong the product’s shelf life.

Before purchasing, verify these key factors to keep away from mistakes:

1.Quality indicators: Compressive power ≥30 MPa (28 days), preliminary putting time 45-90 minutes, fiber bonding electricity (no convenient peeling).

2.Durability: Impermeability ≥0.3 MPa (24h), UV energy retention ≥80%, chemical weight exchange ≤±5%.

3.Certifications: ISO 9001, regional requirements (e.g., CE, ASTM), specialised utility certifications.

4.Construction adaptability: Flexible sufficient for task shapes, weight appropriate for installation, moisture-proof packaging.

Conclusion: Choose Wisely for Project Success

Buying cement blanket is no longer simply a purchase—it’s an funding in your project’s protection and longevity. By focusing on core best indicators, durability, producer certifications, and building adaptability, you can keep away from faulty cement canvas and limit long-term renovation costs. Always pick out authentic producers with obvious check reviews and complete after-sales service. Remember: a small funding in great verification these days can shop you from big losses brought about by means of product failure tomorrow.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province