Solving the Slope Problem: How Cement Blankets Prevent Hillside Erosion

Introduction: The Hidden Danger of Hillside Erosion and the Need for Strong Slope Protection

Hillside erosion threatens communities, infrastructure, and ecosystems globally—triggered by means of heavy rain, wind, or human things to do like construction. It strips topsoil, weakens slopes, and reasons landslides, whilst regular Slope Protection (concrete pouring, stone masonry) is steeply-priced and disruptive. Cement blankets (concrete blankets) provide a higher solution: flexible, quick to install, and durable, they supply instant Slope Protection and combine with polyethylene ditch liner and ditch lining systems. This article breaks down their functionality, installation, and purposes to assist tackle erosion effectively.

Why Hillside Erosion Happens: Causes and Consequences Demanding Proactive Slope Protection

Erosion happens when soil’s inside electricity can’t face up to gravity, worsened by:

Rainfall: Intense downpours dislodge soil, growing runoff that carves gullies.

Wind: Dry, uncovered soil blows away, lowering slope cohesion.

Human Activity: Overgrading, deforestation, or negative drainage quickens damage.

Consequences consist of infrastructure injury (undermined roads/foundations), environmental damage (sediment-clogged waterways), and protection dangers (landslides). Proactive Slope Protection—like cement blankets paired with polyethylene ditch liner and ditch lining systems—is essential to tackle erosion and drainage (a pinnacle reason of slope failure).

What Are Cement Blankets? The Innovative Slope Protection Solution

Cement blankets are prefabricated, bendy mats: a cementitious core (cement, aggregates, additives) sandwiched between geotextile layers (polypropylene/polyester). Activated with water, the core treatment options into a challenging concrete barrier. Key advantages for Slope Protection:

Flexibility: Conforms to uneven slopes for full coverage.

Speed: Installed in hours, treatments in 24–48 hours (vs. days for usual concrete).

Durability: Resists weathering/UV, presenting 20+ years of Slope Protection with maintenance.

Cement blankets don’t substitute drainage—they work with ditch lining structures (including polyethylene ditch liner) to manipulate runoff and stop slope saturation.

Cement Blankets vs. Traditional Slope Protection: Why They Excel

Traditional strategies fall brief in effectivity and cost. Here’s how cement blankets compare, with a center of attention on polyethylene ditch liner and ditch lining structures integration:

Concrete Pouring: Needs heavy equipment, expert labor, and lengthy curing times. It cracks on slopes, and pairing with ditch lining structures provides complexity. Cement blankets are lightweight, crack-resistant, and pair without problems with prefabricated ditch lining systems.

Stone Riprap: Gaps permit erosion, and stones can puncture polyethylene ditch liner. Cement blankets create a seamless barrier, pairing safely with polyethylene ditch liner to channel runoff.

Vegetative Covers: Only work for slight erosion. Cement blankets provide immediately Slope Protection, can be seeded post-curing, and use ditch lining structures to control extra water.

Combining cement blankets with polyethylene ditch liner and ditch lining structures creates a holistic Slope Protection answer for erosion and drainage.

Cement Blankets and Supporting Systems: Integrating Slope Protection with Ditch Lining Systems

Water administration is necessary for slope stability. Ditch lining structures (with polyethylene ditch liner) acquire and redirect runoff, stopping soil saturation. Here’s their synergy with cement blankets:

1. Ditch Lining Systems: Slope Drainage Backbone

Ditch lining structures (above/below ground) give up gully formation and limit water pressure. Polyethylene ditch liner is best for hillsides: lightweight, chemical-resistant, and flexible, it won’t crack beneath soil movement—ensuring long-term drainage efficiency.

2. Cement Blankets + Ditch Lining Systems: Synergistic Protection

Surface Shield: Cement blankets cowl slopes, blocking off raindrop have an impact on and soil displacement (core Slope Protection).

Runoff Channeling: Ditch lining structures (lined with polyethylene ditch liner) set up at slope bases/contours, accumulating blanket runoff and directing it to protected discharge points.

Edge Sealing: Blanket edges anchor to ditch lining systems, stopping water seepage below the blanket and hidden erosion.

This integration ensures complete Slope Protection for floor and subsurface issues.

Installing Cement Blankets: Step-by-Step for Max Slope Protection

Proper set up unlocks cement blankets’ potential—especially with polyethylene ditch liner and ditch lining systems. Follow these steps:

1. Site Preparation

Assess Slope: Measure gradient (1:1 to 3:1 works for blankets) and map drainage paths.

Clear Debris: Remove rocks/roots for a easy floor (uneven terrain reasons curing gaps).

Install Ditch Lining Systems: Dig contour/base ditches (size based totally on runoff), line with polyethylene ditch liner, and impenetrable with stakes to make certain appropriate slope towards discharge points.

2. Prepare the Cement Blanket

Cut to Size: Measure slope, reduce blanket with a utility knife (add 10–15cm overlap for adjoining sections—gaps minimize Slope Protection).

Unroll Carefully: Transport to slope top, unroll downward (use ropes for steep slopes) to keep away from slipping.

3. Secure and Activate

Anchor Edges: Use 60–80cm metal stakes (drive 30cm deep, 50–75cm apart) to invulnerable top/bottom/sides. For ditch-adjacent edges, anchor at once to polyethylene ditch liner (use well matched adhesives if needed).

Hydrate Evenly: Use low-pressure hose to moist the blanket—dry spots won’t cure. Cures in 24–48 hours; keep away from foot traffic.

4. Post-Installation Checks

Fix gaps/loose stakes immediately.

Ensure ditch lining structures (with polyethylene ditch liner) glide freely—clear clogs to stop runoff buildup.

Real-World Applications: Where Cement Blankets Deliver Slope Protection

Cement blankets, paired with polyethylene ditch liner and ditch lining systems, work for various hillside projects:

1. Highway/Railway Slopes

Road/rail corridors reduce via hillsides, risking erosion. Cement blankets provide quick Slope Protection to decrease delays; ditch lining structures (with polyethylene ditch liner) channel runoff away from tracks/roads, stopping washouts.

2. Residential Hillsides

Homeowners face landslide risks. Cement blankets guard yard slopes/foundations; polyethylene-lined ditch lining structures control rooftop/driveway rainwater. Blankets’ low profile preserves aesthetics.

3. Mine Reclamation

Mining creates steep, barren slopes. Cement blankets supply necessary Slope Protection; ditch lining structures (with chemical-resistant polyethylene ditch liner) redirect acidic runoff to treatment. Post-curing, blankets can be seeded.

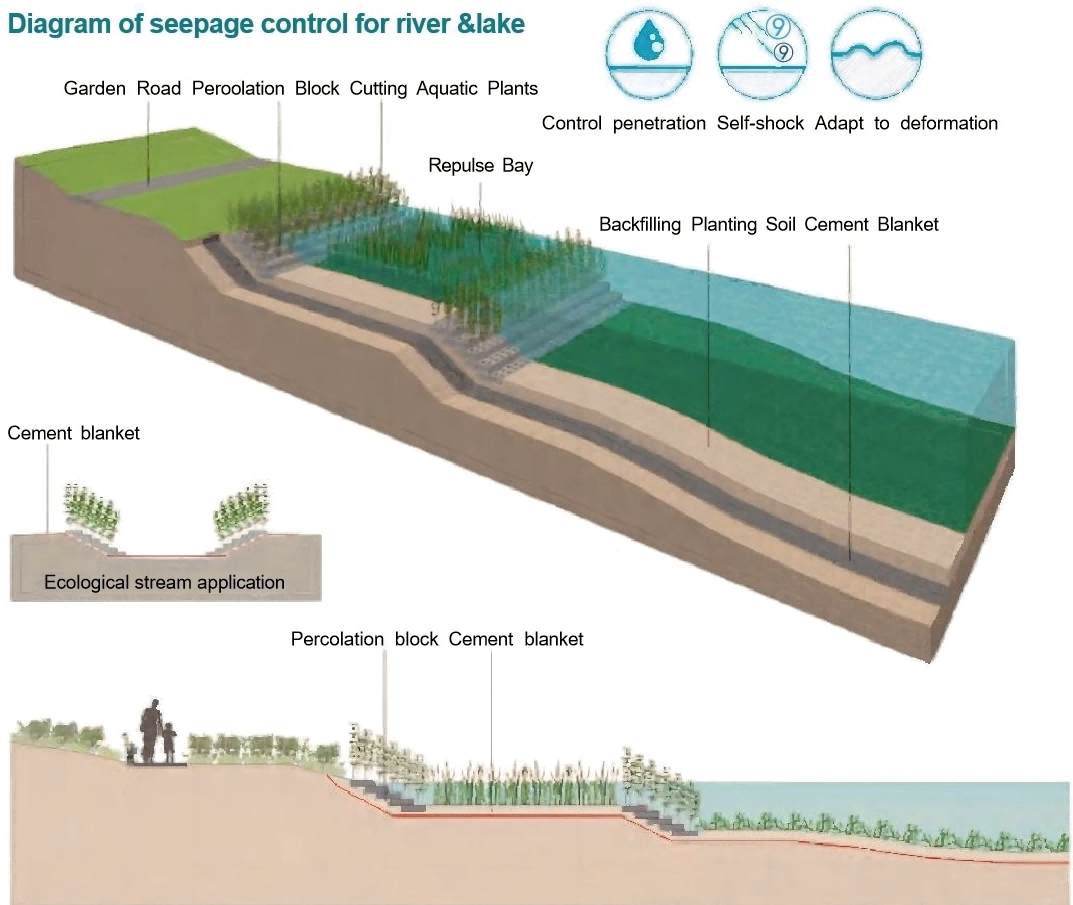

4. Riverbank Hillsides

Riverbanks erode from currents/floods. Cement blankets line slopes above waterlines; ditch lining structures (with polyethylene ditch liner) gather upstream runoff to stop worsening erosion.

Environmental Benefits of Cement Blankets for Slope Protection

Cement blankets (with polyethylene ditch liner and ditch lining systems) are eco-friendlier than usual concrete:

Lower Carbon Footprint: Uses 30% much less cement, reducing emissions. Polyethylene ditch liner is recyclable.

Minimal Disturbance: Lightweight, no heavy equipment—preserves vegetation/wildlife.

Water Conservation: Ditch lining structures minimize runoff, recharging groundwater.

Longevity: Lasts decades, decreasing substitute waste.

How to Choose the Right Cement Blanket and Supporting Systems

Select merchandise for most effective Slope Protection by using considering:

1. Slope Gradient/Erosion Severity

Mild (1:3 slope): Thin blankets (10–15mm) + wellknown polyethylene ditch liner (0.5mm).

Severe (1:1 slope): Thick blankets (20–25mm) + heavy-duty polyethylene ditch liner (1–1.5mm) + bolstered ditch lining systems.

2. Climate/Runoff Volume

High Rainfall: Water-resistant blankets + huge ditch lining systems; UV-stabilized polyethylene ditch liner.

Cold Climates: Freeze-thaw resistant blankets; polyethylene ditch liner (no frost cracking) for ditch lining systems.

3. Compatibility with Ditch Lining Systems

Ensure blankets’ side plan works with your ditch lining structures (e.g., built-in flaps for polyethylene ditch liner attachment to quit seepage).

FAQs About Cement Blankets for Hillside Slope Protection

Q1: How lengthy do cement blankets furnish Slope Protection?

A1: 20+ years. Paired with polyethylene ditch liner (15–20 years), the gadget works a long time with minimal maintenance.

Q2: Can they pair with different Slope Protection methods?

A2: Yes—seed over cured blankets for aesthetics, or use geogrids for steep slopes. They combine with ditch lining structures and polyethylene ditch liner.

Q3: Is polyethylene ditch liner necessary?

A3: Recommended for most projects. Ditch lining structures (with polyethylene liner) manipulate runoff— a pinnacle purpose of slope failure, even with blankets.

Q4: Can I installation them DIY?

A4: Small initiatives (residential yards) can be DIY, however steep/large initiatives want professionals. Poor ditch lining gadget setup reduces Slope Protection.

Q5: Resistant to plant roots?

A5: Yes—cured blankets block roots. Seed over (not under) blankets for vegetation.

Conclusion: Cement Blankets—The Future of Sustainable Slope Protection

Hillside erosion is complex, however cement blankets—paired with polyethylene ditch liner and ditch lining systems—offer a simple, nice solution. They supply immediate, long lasting Slope Protection, manipulate runoff, and reduce environmental impact, outperforming ordinary methods.

Whether defending highways, homes, or mines, this device grants long-term results. As erosion dangers develop with local weather change, investing in these options is vital to shield communities and ecosystems. Start by using assessing your site’s erosion severity, selecting well matched products, and hiring specialists for integral projects—turn unstable slopes into resilient landscapes.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province