Cement Blanket vs. Traditional Concrete: Which Saves Time & Cost for Your Project?

In construction, time and fee are non-negotiable priorities—delays and finances overruns can derail even the most well-planned projects. When it comes to structural reinforcement, waterproofing, or erosion control, two substances dominate: Cement Blanket (also recognised as concrete cloth) and ordinary concrete. But which one provides higher time and price savings? This information compares them throughout 4 necessary areas, highlighting how Cement Blanket and concrete fabric outperform regular concrete in key scenarios—while additionally noting the place normal mixes continue to be the higher choice.

1. Installation Efficiency: Cement Blanket Cuts Project Timelines Dramatically

How Cement Blanket Streamlines Installation

Cement Blanket (a flexible, fiber-reinforced concrete cloth) redefines pace in construction. Here’s why it saves weeks of undertaking time:

No formwork required: Unlike ordinary concrete, which wishes wood or metal varieties to maintain its shape, Cement Blanket is self-supporting. Unroll it without delay over the goal surface—whether it’s a slope, trench, or structure—and impenetrable it with stakes or fasteners.

Rapid curing: Concrete fabric prompts with water (hose it down or let rain do the work) and treatments in 24–48 hours. Traditional concrete requires 7–28 days of curing earlier than it can undergo weight, delaying subsequent phases.

Single-step application: A small group can set up 100+ rectangular ft of Cement Blanket in hours. Traditional concrete needs mixing, pouring, smoothing, and formwork removal—all labor-intensive and time-consuming.

For example, lining a 50-foot drainage trench with Cement Blanket takes 1–2 days total. The identical venture with regular concrete may want to take 1–2 weeks, which includes formwork setup, curing, and teardown.

Traditional Concrete’s Installation Limitations

Traditional concrete’s multi-step technique creates unavoidable delays:

Formwork fabrication and elimination add 3–5 days to most projects.

Mixing requires specific water-to-cement ratios, and pouring needs cautious smoothing to keep away from cracks.

Curing is non-negotiable—rushing the procedure leads to weak, brittle concrete that requires pricey repairs.

For time-sensitive initiatives (e.g., emergency erosion control, post-storm repairs), usual concrete’s sluggish set up makes it impractical.

2. Material & Transportation Costs: Lightweight Concrete Cloth Saves Money

Cement Blanket’s Cost Advantages in Transport & Storage

Cement Blanket’s light-weight plan (typically 2–4 lbs per rectangular foot) interprets to enormous price savings:

Lower transportation costs: A single truck can lift ample concrete material to cowl 10,000+ rectangular feet. Traditional concrete weighs a hundred and fifty lbs per cubic foot—transporting the identical insurance requires 5–10x extra trucks, growing gas and labor costs by using 30–50%.

Minimal storage costs: Cement Blanket rolls are compact and stackable, requiring no distinct storage. Traditional concrete requires on-site mixing stations, silos, or ready-mix deliveries that incur condominium prices and waste (unused concrete hardens and is discarded).

Reduced waste: Concrete material is reduce to dimension on-site, with minimal scraps. Traditional concrete frequently outcomes in 5–10% waste due to over-mixing or spillage.

Traditional Concrete’s Hidden Material Costs

Traditional concrete’s upfront fabric fees may additionally appear lower, however hidden prices add up:

Formwork substances (wood, steel) and disposal charges enlarge budgets with the aid of 15–20%.

Ready-mix concrete fees fluctuate with gas and uncooked fabric costs, main to surprising price range hikes.

Waste disposal expenses for extra concrete and formwork add to long-term costs.

For far off tasks or web sites with constrained access, transportation expenses by myself make standard concrete 2–3x extra highly-priced than Cement Blanket.

3. Construction Complexity & Labor Costs: Cement Blanket Reduces Skill Requirements

Cement Blanket’s Low-Barrier Installation

Cement Blanket requires minimal training, slicing labor fees and decreasing errors:

No specialised abilities needed: General workers can set up concrete cloth—no want for licensed concrete finishers. Traditional concrete requires expert employees to mix, pour, and end the material, which prices 25–40% greater in labor.

Fewer employees required: A group of 2–3 human beings can manage Cement Blanket installation. Traditional concrete desires 5–6 people for mixing, pouring, and formwork, doubling labor expenses.

Fewer equipment needed: Cement Blanket solely requires primary equipment (scissors, stakes, a hose). Traditional concrete wants mixers, trowels, vibrators, and formwork tools—rental expenses for this tools add up quickly.

Traditional Concrete’s Labor-Intensive Process

Traditional concrete’s complexity drives up labor costs:

Skilled concrete finishers command greater wages (often $25–$40 per hour, vs. $15–$20 for popular labor).

Formwork meeting and removal require extra people and time.

Curing monitoring (moisture control, temperature checks) provides ongoing labor hours.

For small to mid-sized projects, labor charges for common concrete can exceed fabric costs—something Cement Blanket avoids entirely.

4. Application Scenarios & Long-Term Value: Which Fits Your Project?

When Cement Blanket (Concrete Cloth) Delivers Maximum Time/Cost Savings

Cement Blanket shines in eventualities the place pace and accessibility count most:

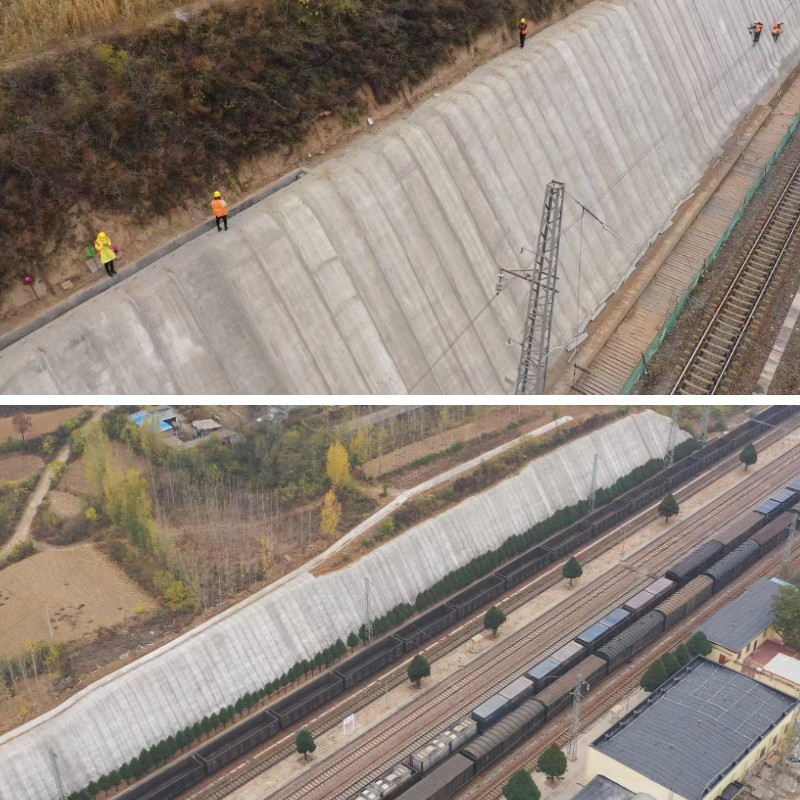

Emergency projects: Flood control, slope stabilization, or transient repairs—concrete material can be hooked up in hours and cured in days.

Remote or hard-to-reach sites: Mountainous areas, rural construction, or tasks with restrained street access—lightweight Cement Blanket avoids pricey heavy-equipment transport.

Erosion manipulate & lining projects: Drainage ditches, ponds, culverts, or preserving walls—no formwork and speedy curing keep weeks.

Small to mid-sized structures: Walkways, patios, or utility trenches—labor and time financial savings outweigh any minor overall performance tradeoffs.

When Traditional Concrete Is More Cost-Effective Long-Term

Traditional concrete stays the higher preference for:

Large-scale structural projects: Bridges, skyscrapers, or foundations—its greater compressive power (3,000–5,000 psi vs. Cement Blanket’s 2,000–3,000 psi) ensures long-term durability.

High-traffic or load-bearing surfaces: Highways, industrial floors, or parking garages—traditional concrete resists put on and tear higher over decades.

Custom shapes or finishes: Architectural factors or ornamental concrete—traditional mixes provide extra flexibility in texture and design.

While standard concrete expenses extra upfront, its most suitable electricity makes it less expensive over 20+ years for high-stress applications.

Final Thoughts: Choosing Between Cement Blanket and Traditional Concrete

Cement Blanket (concrete cloth) is the clear winner for initiatives the place time, labor, and transportation fees are pinnacle priorities—especially emergency repairs, faraway sites, or erosion control. It cuts set up time with the aid of 70% and reduces labor/transport prices via 30–50% in contrast to regular concrete. For large-scale, load-bearing structures, however, common concrete’s sturdiness justifies its greater upfront costs.

Want to make the proper preference for your unique project? I can create a customized time-and-cost evaluation guidelines tailor-made to your task size, location, and requirements—just let me understand if you want it!

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province