Case Study: Successful Large-Scale Water Reservoir Project Using HDPE Geomembrane

Every worthwhile large-scale infrastructure mission has a secret hero. In the world of water conservation and containment, that hero is regularly the High-Density Polyethylene (HDPE) geomembrane. This case study about delves into a hypothetical, however representative, large-scale water reservoir undertaking to divulge how this necessary fabric ensured the project's success, imparting a blueprint for future developments.

Introduction: The Challenge of Modern Water Storage

The demand for reliable, large-scale water storage preferences has with the aid of no skill been greater. Communities, agricultural sectors, and industries all matter on impenetrable reservoirs that cease water loss and defend the surrounding environment. The principal mission in placing up such reservoirs is developing a robust, long-lasting, and truely impermeable barrier. This is the area most useful engineering and specialised materials come into play. For this project, the reply used to be decided in a high-performance HDPE geomembrane, a fabric chosen for its unparalleled sturdiness and impermeability.

Project Overview: Ambitious Goals Require Superior Solutions

The task worried the improvement of a new, 200-hectare water reservoir designed to supply a regional agricultural neighborhood and provide emergency water storage. The site's geology, comprising porous sandy soils, brought a super threat of seepage. Traditional clay liners have been deemed insufficient due to the immoderate hazard of cracking and the sheer extent of fabric required. The predominant goals have been clear: obtain zero leakage, make sure a lifespan exceeding 50 years, and entire constructing internal a strict timeline. The desire of an impermeable geomembrane used to be no longer sincerely an option; it used to be a necessity for the project's viability.

Why HDPE Geomembrane Was the Optimal Choice

After a thorough distinction of all on hand lining materials, HDPE was once as soon as chosen as the definitive solution. The resolution used to be based totally absolutely on a multi-faceted comparison of its properties, which aligned flawlessly with the project's annoying requirements.

Superior Impermeability: The predominant characteristic of the liner is to end water from escaping. HDPE presents an notably low permeability coefficient, developing a in actuality impassable barrier for water and water-borne contaminants. This guaranteed that the reservoir would hold its valuable contents, making the HDPE geomembrane the coronary coronary heart of the containment system.

Exceptional Durability and Longevity: Engineered to stand up to harsh environmental conditions, this geomembrane material is notably resistant to ultraviolet (UV) radiation, chemical degradation, and extreme temperature fluctuations. Its sturdy nature ensures that the liner stays intact and realistic for decades, minimizing long-term safety expenses and concerns.

High Puncture and Tear Resistance: The subgrade of a huge reservoir can be unpredictable. The high-density polymer form of the HDPE geomembrane provides extraordinarily desirable resistance to punctures from sharp rocks or uneven settlement, retaining the integrity of the impermeable barrier at some factor of its issuer life.

Cost-Effectiveness and Installation Efficiency: While the preliminary fabric fee used to be competitive, the real value used to be realized in the set up phase. The availability of massive panels and most desirable welding techniques allowed for quick deployment, drastically accelerating the mission agenda in distinction to desire methods.

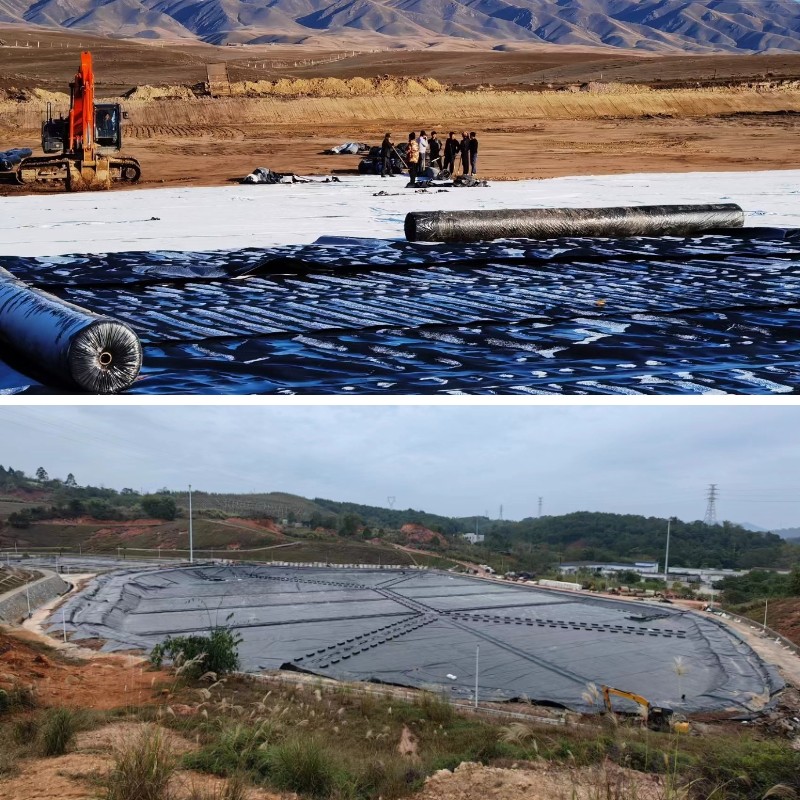

The Installation Process: Precision from Ground Up

The worthwhile implementation of the HDPE geomembrane liner used to be a meticulously deliberate operation. The manner was once as soon as damaged down into a range of essential tiers to make certain flawless performance.

1. Subgrade Preparation: The foundation is paramount. The native soil was once as soon as cautiously graded and compacted to create a smooth, tightly closed flooring free of sharp protrusions. This step used to be quintessential to cease any stress elements that ought to compromise the impermeable geomembrane after installation.

2. Panel Deployment and Welding: Large rolls of the HDPE geomembrane had been deployed for the duration of the prepared subgrade. The core of the set up used to be as soon as the welding process. Certified technicians used dual-hot wedge welders to fuse the panels together, creating continuous, monolithic seams. Every inch of these welds was once as soon as non-destructively examined to make positive they have been as sturdy and impermeable as the guardian cloth itself.

3. Quality Assurance and Protection: A rigorous best manipulate protocol was once as soon as maintained throughout. Once the geomembrane material was once as soon as entirely welded and tested, a defending layer of non-woven geotextile used to be as soon as regularly placed on pinnacle to cushion the liner from any incidental harm in the direction of subsequent operations or from the hydraulic stress of the water.

Overcoming Project Hurdles

No project of this scale is without its challenges. Unpredictable local weather threatened to prolong the sensitive welding process. This used to be mitigated via deploying mobilephone local weather shelters and adjusting work schedules. Furthermore, the large location required a pretty geared up logistics plan to sequence the transport and placement of the HDPE geomembrane rolls besides inflicting congestion or damage on-site. The mission team's proactive planning and the adaptable nature of the geomembrane material set up allowed them to navigate these hurdles effectively.

Measurable Outcomes and Lasting Benefits

The completion of the reservoir marked a resounding success, with blessings that had been besides lengthen apparent and will be sustained for generations.

Zero Leakage Performance: Post-commissioning monitoring set up that the reservoir maintained its water diploma with no measurable loss, validating the ordinary overall performance of the impermeable geomembrane system.

Environmental Safeguarding: By stopping seepage, the liner moreover protects the close by groundwater from any potential contamination, aligning with the project's sturdy environmental stewardship goals.

Economic Efficiency: The rapid set up of the HDPE geomembrane led to the venture being carried out in develop of schedule, ensuing in huge fee savings. The long-term economic benefit lies in the minimal preservation required and the guaranteed water safety for the region.

A Model for Future Projects: The success of this assignment has hooked up a new benchmark for related large-scale water containment projects, showcasing the HDPE geomembrane as the industry-standard solution.

Conclusion: A Blueprint for Water Security

This case research about powerfully illustrates that the want of lining material can make or smash a main water containment project. The choice to make use of a top notch HDPE geomembrane used to be as soon as the cornerstone of this project's success. Its set up impermeability, daring durability, and surroundings pleasant set up approach right away translated into a reliable, cost-effective, and environmentally sound reservoir. For any entity questioning of a large-scale water storage project, the proof is clear: specifying a sturdy geomembrane material like HDPE is now now not in easy phrases a technical detail—it is the most essential funding in the project's long-term viability and success.

Ready to find out how an ideal geomembrane reply can tightly closed your subsequent project? Contact a specialist these days to speak about your special requirements and make certain a watertight future.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province